Calcium carbonate is a vital inorganic chemical. It is widely used in industries like plastics, rubber, coatings, and papermaking. In recent years, the use of synthetic resins and chemicals has kept growing. So, energy use has increased daily. In the plastics, rubber, and other industries, people are considering adding fillers. But these are inorganic fillers. These fillers are rich in resources and cheap. They are added to synthetic polymers. We want to add as much inorganic filler (like calcium carbonate) as we can to plastics and rubbers. But, we must still keep the physical and mechanical properties of the products.

Plain calcium carbonate is an example of an ordinary inorganic filler. It is hard to meet these requirements. They need to be changed to improve their overall performance. The composite material industry is experiencing rapid growth. Calcium carbonate is now a filler and an important modifier.

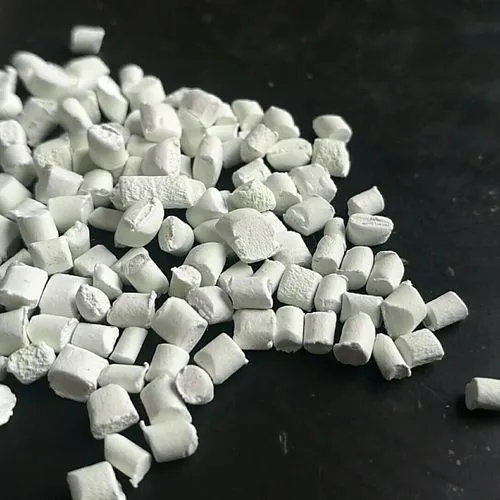

Active calcium carbonate has a great filling ability in plastic. It can cut costs. It can improve the hardness, stiffness, size stability, and heat stability of products. We modify regular calcium carbonate to get active calcium carbonate. This way, it can fill and modify composite products. These include changes to the crystal form, particle size, and size range. They also change the surface properties of calcium carbonate.

Calcium carbonate modification method

One is to change the particle size so that the calcium carbonate particles are fine or ultra-fine. This includes changing the crystal form and size range of the particles. Using fine or ultra-fine calcium carbonate helps. It has different crystal forms. This improves its ability to spread resin. It also provides reinforcement effect in plastics, rubber, and other products. These products have tiny particles and a large surface area.

This method requires updating the old process. It needs better carbonization, pulverization, and drying of calcium carbonate. The production process is complicated. When mass-producing, it’s hard to dry the items and they cost a lot to make.

The second is to improve the surface of calcium carbonate. This will make it go from inorganic to organic. This will increase its compatibility with organic resins. This change will also improve the making and quality of products.

This method mainly uses amphiphilic molecules. They have both inorganic and organic groups. These include surfactants, long-chain acids, and coupling agents. They use them to modify the surface of calcium carbonate. Its process and equipment are relatively simple and easy to implement. The coupling agent is new. It treats calcium carbonate of various sizes. The modification is very good. It has been used more and more in making composite materials. These materials include plastics and rubber. This is an effective way to expand the new varieties of calcium carbonate fillers.

Organic matter suitable for calcium carbonate modification

Many substances can change the surface of calcium carbonate. But, past research has mostly focused on using organic acids. They use them to make active calcium carbonate. Organic acid’s role on the surface of calcium carbonate is mainly physical adsorption. It provides lubrication between the interface of calcium carbonate and resin. Adding organic acid can change the rheological and processing properties of the material. But, it barely helps the physical properties of the product.

Recent studies have shown that when calcium carbonate is treated with a coupling agent, the agent’s inorganic and organic ends can react with its surface. They can also react with organic resins. At the same time, they can get tangled up with organic resin. In the presence of a crosslinking agent, crosslinking can also occur. This effect changes the surface polarity of calcium carbonate. This also increases the adhesion between calcium carbonate and organic resin. So, adding a coupling agent can enhance the processing of calcium carbonate-filled products. It can also improve the products’ physical and mechanical properties.

Titanate and aluminate coupling agents are better. They modify the surface of calcium carbonate. However, calcium carbonate treated with titanate coupling agents will change its color. This happens due to oxidation when used in some polymers. During storage or processing, the organic end of the titanate molecule can break apart. This can happen due to hydrolysis or alcoholysis. At the same time, the thermal decomposition temperature of titanate is lower than that of aluminate. So, it is better to use aluminate coupling agents. They are used to treat calcium carbonate.

Calcium carbonate activates with aluminate coupling agents. The molecules of these agents are amphiphilic. They have one inorganic-philic end and one organic-philic end. The coupling agent acts on the surface of calcium carbonate. The calcium and carbonate ions on the surface of the particles meet water in the air and hydrolyze. This creates an alkaline, oleophobic hydroxyl surface.

The surface hydroxyl groups of calcium carbonate can bond with the inorganic-philic end of the aluminate coupling agent. This combination produces surface-modified calcium carbonate particles. These calcium carbonate particles have a modified surface. They are blended with resins. The organic ends of the coupling agent molecules can tangle with the resin molecules. The coupling agent activates the calcium carbonate. This improves its affinity with organic resin. It modifies and strengthens the resin.