The negative electrode material is one of the core materials of lithium-ion battery, it determines the rate performance of lithium-ion battery, it also affects the efficiency of initial charge and discharge and stability of battery cycle. Natural graphite negative electrode material is made from natural flake graphite. Through process of grinding, spheroidization, grading, purification and surface modification, natural graphite anode material is obtained. It has advantages of low price, large storage capacity, non-toxicity and good conductivity.

Spherical graphite has become a popular replacement for lithium-ion battery anodes. It has good conductivity, high crystallinity, low cost, and a long cycle life. It also has a low and flat charge and discharge potential. We have developed a new negative electrode material for lithium-ion batteries. It uses natural flake graphite, a modified form of spherical graphite. The lithium-ion battery industry has entered a new era.

Why use spherical graphite?

Due to characteristics of good conductivity and high crystallinity, natural graphite is still the most widely used negative electrode material. However, natural graphite also has some shortcomings: low specific capacity, fast attenuation, poor cycle performance and insufficient rate performance.

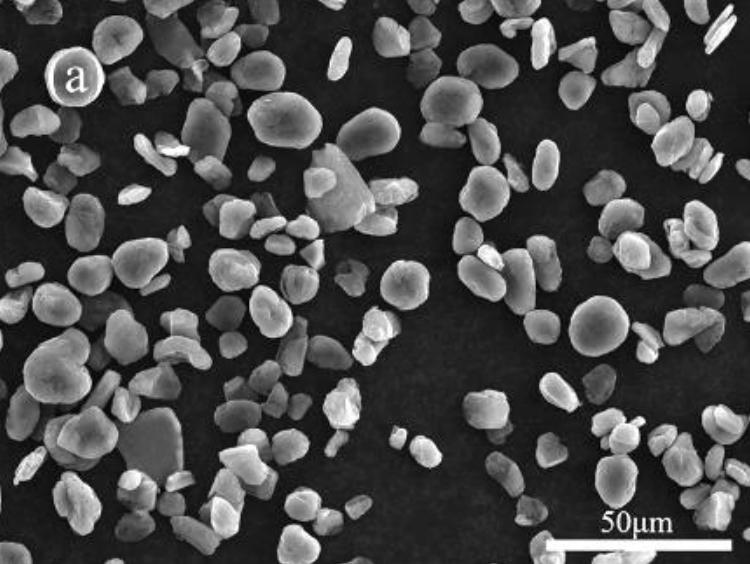

Modify graphite to optimize the performance of anode material can solve these problems. One of the main modification methods at present is spheroidization. Spheroidized natural graphite material have a smaller specific surface area and a higher tap density, these advantages make lithium-ion battery have higher first coulomb efficiency, higher reversible charge and discharge capacity, and better cycle stability.

How to get spherical graphite?

Spherical graphite is made with high-quality high-carbon natural flake graphite as raw material. By adopting advanced processing technology, we can obtain spherical graphite with different fineness and ellipsoidal shape.

The specific methods include wet method and dry method.

In wet method, graphite particles gradually become spherical or ellipsoidal through collision, impact force and shear force during grinding. In wet method, jet mill can be adopted.

The dry method mainly refers to depolymerization and surface modification. The modification equipment promotes the spheroidization of graphite, and make particle surface smooth. The dry method is more efficient than the wet method.

Graphite spheroidization related products

Qingdao Epic Powder Machinery Co., Ltd. has been committed to the research and development of powder processing equipment for many years. It has various types of powder machinery, including the mills, classifiers and modifiers. Among them, the spiral jet mill is suitable for processing spherical graphite. It uses high-speed airflow to achieve grinding of stone-to-stone and material-to-material, thus production efficiency is improved. Moreover, grinding and shaping at the same time improves the yield rate. What’s more, Qingdao Epic has developed four continuous modifiers, including: pin-mill modifier, turbo-mill modifier, three-roller modifier and multi-rotor–mill modifier.

If you have any related needs or questions, please contact Qingdao Epic directly.