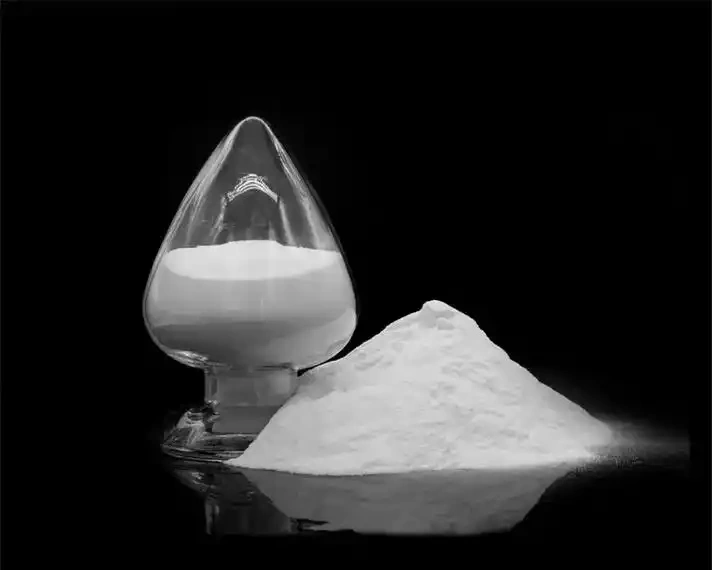

White carbon black is modified silicon dioxide, which is a general term for white powdered X-ray amorphous silicic acid and silicate products. It mainly refers to precipitated silica, fumed silica and ultrafine silica gel. It also includes powdered synthetic aluminum silicate and calcium silicate. White carbon black is a porous substance, composed of SiO2·nH2O. Here, nH2O exists in the form of surface hydroxyl groups. It dissolves in caustic alkali and hydrofluoric acid, but insoluble in water, solvents, or acids (except hydrofluoric acid). It is heat-resistant, non-combustible, odorless, and has excellent electrical insulation properties.

Element

White carbon black is mainly divided into precipitated and fumed silica based on production methods. Fumed silica is a white, amorphous, translucent, gel-like nanoparticle (particle size less than 100nm). It is non-toxic and has a huge specific surface area. Fumed silica is pure nano-silica with up to 99% purity and particle size of 10-20nm. However, its preparation process is complex and expensive.

Precipitated silica is divided into traditional and special precipitated silica. The traditional method uses sulfuric acid, hydrochloric acid, CO2, and water glass as basic raw materials.

Special methods include supergravity technology, sol-gel, chemical crystallization, secondary crystallization, and reverse micelle methods.

Precipitated silica is mainly used as a reinforcing agent for natural and synthetic rubber, and as a toothpaste abrasive. Fumed silica is mainly used as a reinforcing agent for silicone rubber, coatings, and unsaturated resin thickeners. Ultrafine silica gel and aerogel are mainly used as matting agents, thickeners, and plastic film opening agents.

As an environmentally friendly and excellent additive. White carbon black is mainly used in rubber products (including high temperature vulcanized silicone rubber), textiles, papermaking, pesticides, and food additives.

The main method of making white carbon black

The traditional method of preparing white carbon black uses sodium metasilicate, silicon tetrachloride, and tetraethyl orthosilicate as silica sources. Except for sodium metasilicate, the other materials are costly. The new method uses inexpensive non-metallic minerals as silica sources, significantly reducing production costs.

White carbon black is generally divided into precipitated silica and fumed silica based on production methods. Fumed silica is a white, amorphous, flaky, translucent solid gel-like nanoparticle (particle size less than 100nm), non-toxic, with a huge specific surface area. Fumed silica is entirely nano-silica, with a product purity of up to 99% and particle size of 10-20nm. However, its preparation process is complex, and it is expensive.

Precipitated silica is further divided into traditional and special precipitated silica. The traditional method uses sulfuric acid, hydrochloric acid, CO2, and water glass as basic raw materials to produce silica. Special methods include supergravity technology, sol-gel, chemical crystallization, secondary crystallization, and reverse micelle methods. Precipitated silica is mainly used as a reinforcing agent for natural and synthetic rubber, and as a toothpaste abrasive. Fumed silica is mainly used as a reinforcing agent for silicone rubber, coatings, and unsaturated resin thickeners. Ultrafine silica gel and aerogel are mainly used as matting agents, thickeners, and plastic film opening agents.

New method for making white carbon black

The new method mainly uses non-metallic minerals and their derivatives as silica sources, employing the precipitated silica method. The key technology is converting crystalline silica and silicates into amorphous silica. The raw materials include wollastonite, opal, halloysite, olivine, serpentine, kaolin, hard kaolin, coal gangue, and fly ash.

Difference Between Silica and Carbon Black

In fact, white carbon black and carbon black are completely different substances. The name “white carbon black” is mainly due to its similar reinforcing function to carbon black. White carbon black’s main component is silica, but it is different from ordinary silica. White carbon black is silica that has been physically and chemically modified to increase its activity.

Uses of white carbon black

Rubber products

White carbon black is used in colored rubber products to replace carbon black for reinforcement, meeting the need for white or translucent products. White carbon black also has exceptional adhesion, tear resistance, and heat-aging resistance, so it can replace some carbon black in black rubber products. This helps achieve high-quality rubber products, such as off-road tires, engineering tires, and radial tires.

Agricultural chemicals

In agricultural chemicals, such as pesticides and high-efficiency spray fertilizers, white carbon black is used as a carrier, diluent, or disintegrant. When used as a disintegrant in water-dispersible granules (WDG), it improves suspension rate, with a recommended content of about 10%. It maintains long-lasting effectiveness because its ultra-high surface area provides strong adsorption, excellent suspension, good affinity, and chemical stability. Even under rain, washing, and heat conditions, it can remain unchanged for a long time.

Daily chemical products

White carbon black is used as a filler and abrasive in transparent colored and opaque toothpastes. These toothpastes have good flexibility, dispersibility, smooth and soft paste, and excellent abrasiveness, without damaging the toothpaste tube. It helps maintain the stability of medicinal toothpaste. Especially, it has good compatibility with fluorides, avoiding the formation of insoluble salts when using calcium salts as abrasives.

Binder

Used in adhesives made of natural rubber or synthetic rubber, it provides thixotropy and reinforcement. At the same time, due to its stretchability, it can also improve adhesion. It is of high quality and low price.

Anti-caking agent

White carbon black can be used in various products to improve free flow. Such as lawn fertilizers, fungicides, grinding wheel abrasives, laundry bleaches, phenolic injection-molded urotropine, phenol and urea plastic products, and rubber vulcanization and anti-caking mixtures.

Papermaking filler

Using white carbon black as a paper filler can improve ink penetration resistance and mechanical strength, increase whiteness, and reduce unit weight. It effectively achieves lightweight paper, lowers production costs, and enhances paper performance.

Additionally, it can be used in many industries, including fire retardants, feed, cosmetics, matting agents, pigments, and paints.

Gas Phase Applications

Fumed silica is one of the most important high-tech ultrafine inorganic new materials. Due to its small particle size, it has a large specific surface area, strong adsorption, and high surface energy.

It has high chemical purity, good dispersibility, and special properties in heat resistance and electrical resistance. With superior stability, reinforcement, thickening, and thixotropic properties, it has unique characteristics in many fields.

Fumed silica, also known as “nano white carbon black,” is widely used in various industries as an additive and catalyst carrier. It is used in petrochemical, decolorizing agents, matting agents, rubber reinforcement, plastic fillers, ink thickeners, and more. It serves as a metal polishing agent, insulation filler, high-end cosmetic filler, and coating material. It is also used in pharmaceuticals, environmental protection, and other fields. It provides new material foundations and technical guarantees for the development of related industries. Fumed silica has unique functions in magnetism, catalysis, light absorption, heat resistance, and melting points compared to conventional materials.

Conclusion

In the future, white carbon black will focus more on functional modifications, such as the development of flame-retardant, magnetic, and high thermal conductivity white carbon black to meet specific industrial needs. At the same time, environmentally friendly production methods and smart manufacturing will be important directions for future development. In summary, white carbon blacks play a crucial role in the rubber industry.

Its strong reinforcement capability and wide applicability make it an indispensable material.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !