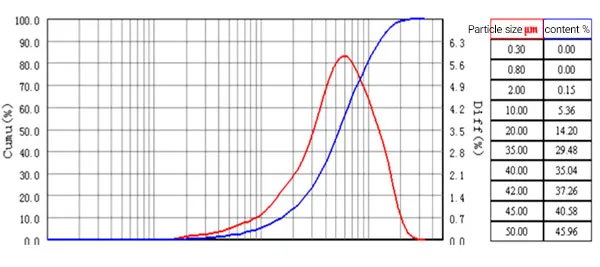

Powder laser particle size analysis is a complex method. It determines the size distribution of powdered materials. This method uses laser diffraction to measure how particles scatter laser light. It can accurately and quickly measure particle sizes in a medium. This technique can analyze particles from nanometers to millimeters. It is invaluable in industries like pharmaceuticals, cosmetics, and materials science.

Particle size analyzers from different manufacturers and models often have different designs. They have different optical designs. For example, linear and folded paths, pre/post-Fourier transform, and laser size. They also have Fourier lenses of different sizes and focal lengths. And different numbers and distributions of detectors. Plus, different specs for sensitivity, noise, and optical parts. These differences cause differences in the light energy distribution of the same particle.

Similarly, changes to the optical path or devices of the powder laser will also cause errors.

Let’s take a look at the reasons that may affect the deviation of the powder laser particle size analyzer.

Light energy distribution inversion algorithm affects particle size test results

In actual tests, the instrument’s signal is composite. One detection’s signal is the result of many particle signals being added together. The algorithm separates the mixed signal. It does this based on how light energy is distributed among particles. The particles have different sizes. This separates the detected particle’s size from the composite signal.

The signals of different detectors differ a lot. For example, the light intensity of large particles is much greater than that of small ones. Also, there are factors like unstable light sources and background noise. So, the software algorithms need to be very good. The models have different optical designs and detector distributions. So, the software algorithms must also differ. This will lead to different results in the inversion calculation process.

Despite the above two main reasons, different analyzers use spherical standard materials. These include glass beads and latex particles with known sizes. These should be able to accurately measure true particle sizes.

However, particles in nature are usually irregular, that is, non-standard spherical. The conditions for particle size equivalence are different in instruments with different hardware. The inversion algorithms also differ. This will lead to different results.

In general, different instruments measure different particle sizes. They get different results for the same sample. These results are normal if they are in the credible range. They are abnormal if they are standard spherical samples. They reflect the sample’s true size.

Different test conditions affect the particle size test results

In the actual test of the powder laser particle size analyzer, many human factors affect it. These include: representativeness in sampling, centering of the instrument, optical settings, the sample cycle, the medium for dispersion, choice of dispersant, processing of the sample, and the quality of the stabilizer. There are also objective factors, like temperature, power supply, and vibration. These factors cause differences in results.

In summary: Non-spherical objects have no true size. Their “true size” varies by definition. When choosing a particle size analyzer, users care about accuracy first. But, as mentioned above, particle size measurement has no concept of “accuracy”.

Summarize

Powder laser particle size analysis offers several advantages over traditional sizing methods. It yields quick results, high reproducibility, and requires little sample prep. Also, this technique can be adapted for dry and wet samples. It is versatile for different applications. Knowing the particle size distribution can help manufacturers. It can optimize processes and improve product quality. It will also help them meet industry standards.

Qingdao Epic Powder Machinery Co., Ltd. is a professional powder equipment manufacturer. The products include: jet mills, ball mill, air classifiers and modifiers. Surface coating equipment from Qingdao Epic includes: pin- mill modifier, turbo- mill modifier, three-roller modifier and multi-rotor -mill modifier.

If you have any related needs or questions, please contact Qingdao Epic directly.