Barium Sulfate, or BaSO₄, is an inorganic compound. It is found widely in nature. It is a key raw material in the chemical and pharmaceutical industries, and many others. Barium sulfate’s unique properties make it very valuable in many applications.

Basic properties of barium sulfate

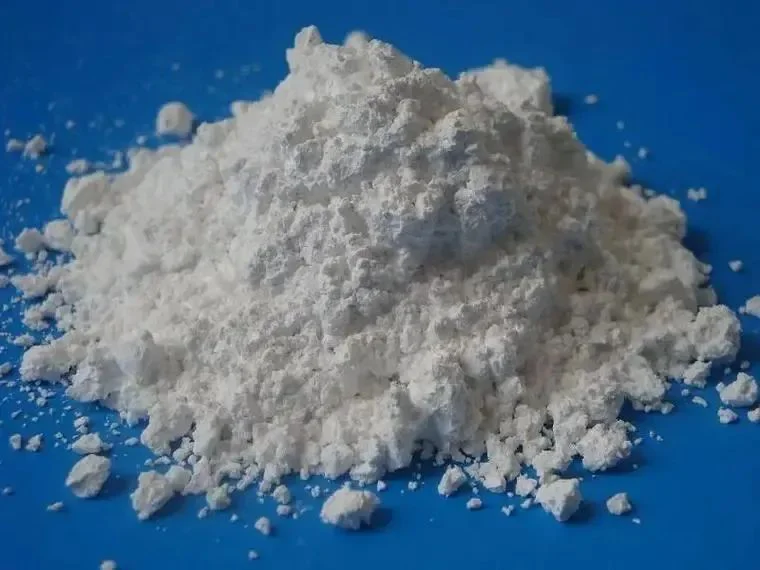

Barium sulfate is a white or colorless crystalline powder. It is odorless, tasteless, and has a high density of about 4.50g/cm³. It is poorly soluble in water, acids (except HF), and alcohol. It is slightly soluble in hot, concentrated sulfuric acid. This property makes barium sulfate very popular. It is stable and insoluble in common solvents. Also, BaSO₄ has a melting point of 1580°C. This shows good thermal stability and expands its uses.

Barium sulfate is stable and does not react easily with other substances. Its strong ionic bonds make it so. However, under certain conditions, the stability of BaSO₄ may be affected. These include a high-temperature molten state or a strong acid, except hydrofluoric acid. Barium sulfate is used as an X-ray contrast agent in medicine. Its insolubility in water and acid is crucial for safety and accuracy in exams.

The main application areas of barium sulfate

Barium sulfate, also known as barite, is a metal sulfate with the molecular formula BaSO₄. It is a white or light yellow, odorless powder or small crystals. It is almost insoluble in water at room temperature. Barium sulfate has many uses, due to its unique properties.

Paper Industry

In the papermaking industry, BaSO₄ plays an important role. Barium sulfate is often used as a filler in white and coated paper. This filler can improve the paper’s whiteness and coverage. It can also enhance its printing performance, making the prints more vivid.

Plastics Industry

The plastics industry uses barium sulfate as a filler for ABS raw materials. It greatly improves the plastic’s gloss. It also enhances its strength and wear resistance. Also, BaSO₄ can be used as a separator in plastics. It reduces the amount of pigments and saves about 10% in costs.

Paints and coatings

Barium sulfate is also widely used in the field of paints and coatings. To make paints, mix barium sulfate with raw materials. These include titanium dioxide and silica. This controls the paint’s adhesion and color, making it shinier. In coatings, BaSO₄ is ideal for pigment topcoats and varnishes. It has low cohesion, low light dispersion, and fine particles. It also has excellent chemical and weather resistance. Barium sulfate has a high filling property. It is suitable for various coatings, such as primers and thick primers. It can maintain good uniformity and smoothness even with high filling.

Medical field

In the medical field, BaSO₄ is mainly used as a contrast agent for X-ray or CT examinations. Barium sulfate can absorb X-rays in the intestines. It can clearly show the intestinal structure. It is a common material for digestive tract imaging. After using contrast agents, patients need to drink more water. It will help metabolize the agents in their bodies.

Oil and gas drilling

Barium sulfate is also an important weighting agent for oil and gas drilling muds. BaSO₄, in the mineral barite, is dense and soft. It has stable chemistry. So, it is an ideal weighting material. It helps increase the density and stability of drilling fluids.

Building Materials and Construction

In building materials, barium sulfate makes radiation-proof cement, mortar, and concrete. These materials use barium sulfate to absorb X-rays. They replace lead plates in nuclear reactors, labs, and X-ray-proof buildings. Also, barium sulfate makes drainage pipes and speakers. It isolates noise and murmurs.

Other applications

BaSO₄ is also widely used in rubber, ink, and pigments. It’s in cosmetics and other industries too. In the rubber industry, BaSO₄ is a filler. It can increase the hardness of silicone rubber and reduce its elasticity. In ink applications, barium sulfate’s low wear and high gloss make it ideal for high-quality inks. Its color stability is a plus. In cosmetics, barium sulfate is used as a filler, such as one of the ingredients in lipstick.

Precautions for handling barium sulfate

When handling barium sulfate (BaSO₄), take safety precautions. This is to protect yourself and the lab. Barium sulfate is stable and non-toxic under normal conditions. But, it may pose some risks in certain situations. The following are some precautions when handling BaSO₄:

Personal protection

Always wear the right protective gear when handling. This includes a lab coat, goggles, gloves, and lab shoes. Do not touch BaSO₄ powder or solution, especially the eyes, skin, and mouth.

Operating Environment

Operate in a well-ventilated area to reduce the accumulation of harmful gases or dust. Avoid pouring barium sulfate solution into the sewer unless necessary. It can pollute the environment.

Avoid ingestion and inhalation

To prevent accidental ingestion of Barite, do not put your fingers or tools into your mouth. Avoid inhaling BaSO₄ dust into the respiratory tract, especially during operation.

Avoid contact with strong acids

Barium sulfate can slowly dissolve in concentrated sulfuric acid. This produces barium hydrogen sulfate. Avoid contact between Barite and strong acids such as concentrated sulfuric acid.

Waste Disposal

Dispose of the waste BaSO₄ solution and lab waste as directed. Follow the laboratory’s waste management policy to reduce environmental impact.

Storage

Keep barium sulfate in a dry, well-ventilated area away from fire, heat sources, and other flammable materials.

Barite high whiteness ultrafine grinding technology

High-whiteness, finely crushed barite powder comes from crushing, washing, and whitening barite ore. The powder keeps the mineral’s crystal structure. It’s widely used in coatings, rubber, plastics, papermaking, ceramics, and other industries. Some large and medium-sized paint factories in China use it to replace titanium dioxide in paint. It is a high-quality filler.

Barite coarse crushing process

The specific gravity of barite is relatively large. The separation is called gravity separation. It is based on the difference in specific gravity between barite and its gangue. The gravity separation method for selecting barite has three advantages. It can select a large particle size, a wide range of sizes, and it has a high ore processing capacity. The gravity separation method is key in barite beneficiation. The gravity separation method purifies barite ore. It is efficient, energy-saving, and eco-friendly. It can also achieve ideal beneficiation indicators. It has excellent recovery and treatment effects on coarse and fine barite.

In new barite beneficiation plants, gravity separation is now the key method. The barite gravity separation equipment is a jig. The jig can separate coarse, medium, and fine barite ores. It works well. It can effectively increase the specific gravity of barite. It uses circulating water for operation. No reagents are needed in the beneficiation process. It has no pollution to the environment. It is a new, eco-friendly, energy-saving method to upgrade barite. It is highly efficient.

Barite fine grinding process

After several crushings using powder technology, the barite ore is now a micron-level fine material. It is roasted in a furnace for 2.5 hours to become clinker. After washing with water to remove alkali, it is pulped after dilute acid washing. Sulfuric acid and aluminum powder (acid dissolution, bleaching) are added to the reactor. The reaction is stirred at boiling temperature for 2.5 hours to obtain bleached material. Wash away the soluble salts with clean water. Then, filter and dry the product at 170℃. The product’s performance meets the IS03262 barite b grade quality standards. Ultrafine powder with whiteness ≥90% and fineness above 98% ≤2μm. It can fully replace precipitated barium sulfate in making paper, rubber, paint, and plastics. It has better performance and broader industrial applications.

Barite jet mill ultrafine grinding project

This customer is the first to use a German airflow crusher in the domestic barite industry. To boost our output, we compared many makers of ultrafine powder equipment, both domestic and foreign. We decided to cooperate with EPIC Powder. Their equipment is a large jet mill. It is used in the domestic non-metallic mining industry. It has a gas consumption of 120 cubic meters per minute.