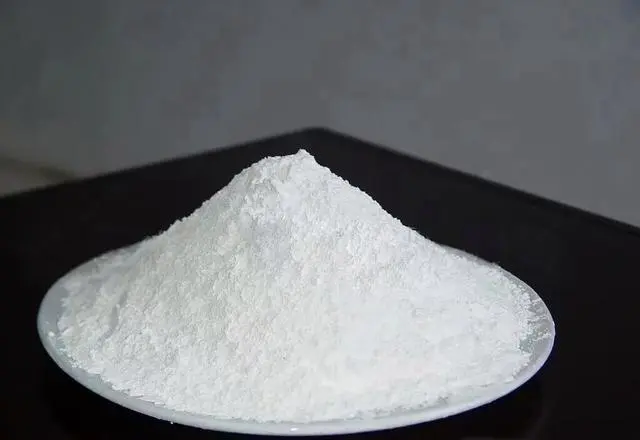

Calcium carbonate is a common powder filler. It’s often found in marble and calcite grinding. Many industries use it. These include plastics, rubber, coatings, papermaking, chemicals, and building materials. The rise of green production creates an opportunity for calcium carbonate companies. They can now make greener products to meet new market demands. The calcium carbonate industry has been experiencing stability recently. But, the market still presents numerous challenges. Prices fluctuate based on different downstream industries.

Calcium carbonate is a mineral. It has been used in industries and ceramics in recent years. Calcium carbonate powder has also played a significant role. Next, let’s discuss its specific functions in the ceramic glaze industry.

Can promote glaze melting

The original ore of calcium carbonate is calcite and marble. This ore is also a solvent. It not only lowers the melting point of the glaze but also makes the glaze easier to melt. This improves the fluidity and moistness of the glaze. It can also helps the seed material to crystallize. This makes the glaze surface more even and delicate. The ceramics appear smoother and more pleasing to the eye visually.

Adjusting the color of the glaze

Adding the right amount of calcium carbonate to the glaze can make the surface white or light yellow. This makes the dull color richer and brighter.

Improve the transparency of glaze

Adding the right amount of calcium carbonate to the glaze can make it more see-through. This can better show the texture of the ceramic object.

Increase the hardness and wear resistance of glaze

Adding the right amount of calcium carbonate to the glaze can make the shaft harder. It will be more durable and less likely to be scratched. This is crucial for producing ceramic objects for daily use.

Adjusting the shrinkage of glaze

Adding the right amount of calcium carbonate powder can make the glaze and the body shrink at the same rate. This reduces the warping and cracking of ceramic objects in production.

Reduce the thermal expansion coefficient of the glaze

Calcium carbonate can reduce the glaze’s thermal expansion coefficient. Adding the right amount of calcite can stabilize the thermal expansion of the glaze. This will reduce the cracking and bending of ceramics at high temperatures.

After researching the industry, we found that calcium carbonate is worth considering. It’s crucial for ceramics. It is not widely used in the ceramic industry. On one hand, it has not been promoted. On the other hand, the amount used in this industry is relatively small. Without technical and product support, calcium carbonate has specific requirements and effects. This has resulted in calcium carbonate manufacturers neglecting it. They’ve neglected it as a key sales item.