Powder equipment has important applications in the preparation process of battery anode materials. Commonly used materials for battery anode include graphite, metallic lithium, thorium, lithium cobalt oxide, etc. These materials need to be prepared and processed through powder equipment.

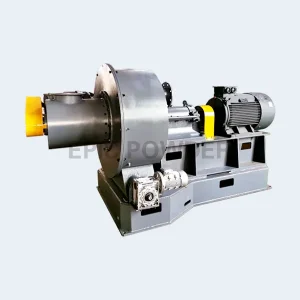

First, powder equipment is used for grinding and refining materials. Battery anode materials must reach a certain particle size and size distribution to ensure battery performance and cycle life. Powder equipment, such as ball mills, grinders, etc., can refine materials to achieve the desired particle size and distribution.

Secondly, powder equipment plays an important role in materials’ mixing and uniformity control. Battery-negative electrode materials usually must be mixed with conductive agents, binders, and other components to ensure uniformity and improve battery performance. Powder equipment such as mixers and stirrers can mix and uniformly regulate materials to ensure the consistency and stability of negative electrode materials.

In addition, powder equipment is also used in the drying and baking materials. Battery-negative electrode materials need to go through a drying and baking process to remove moisture and volatile matter and improve the stability and performance of the material. Powder equipment such as dryers and baking ovens can dry and bake materials to ensure the dryness and quality of the materials.

All in all, powder equipment has a key application in the preparation process of battery anode materials. Higher-quality battery anode materials can be prepared through processes such as grinding, mixing, and drying of powder equipment, thereby improving battery performance and life.