Calcium carbonate is an important and widely used inorganic salt. Calcium carbonate is usually divided into heavy and light forms. This is based on different processing methods. Calcium carbonate is the most widely used powder filler in the rubber industry. It comes in two forms: heavy and light.

Related concepts

1. Calcium carbonate. It is an inorganic compound. It is white powder or a colorless crystal. It has no odor or taste. It is commonly known as gray stone, limestone, stone powder, marble, or calcite. It is an alkaline compound. It is basically insoluble in water but soluble in acid. It can be found in rocks such as aragonite, calcite, chalk, limestone, marble, and travertine. It is an important building material and has many industrial uses.

2. Heavy calcium. Heavy calcium carbonate is also known as ground calcium or heavy calcium. It is made by physically processing of natural calcite, limestone, dolomite, chalk, shells, etc.

3. Light calcium. Light calcium carbonate is also known as precipitated calcium carbonate or light calcium for short. It is made by chemical methods.

4. Mesh number. It refers to the number of holes on the screen per square inch. 50 mesh means 50 holes per square inch. 500 mesh means 500. The higher the mesh number, the more holes.

Application of calcium carbonate in rubber

Light calcium carbonate is widely used to fill natural rubber. It is also used in styrene-butadiene, cis-butadiene, nitrile-butadiene, and ethylene-propylene rubbers. Adding calcium carbonate improves some rubber properties. This also expands the range of uses for rubber. With rubber, calcium carbonate can reduce shrinkage. It also improves rheology and controls viscosity during processing.

Calcium carbonate strengthens rubber products. It also stabilizes their size. It can grow the rubber volume and cut product costs. It can make rubber more stable and harder. It can also make it stiffer and easier to process. It improves the heat resistance and astigmatism of rubber. The rubber it makes is stronger than steel in some ways. It is as hard as jade. It also resists wear, high temperatures, and aging. It has many uses. These include electronics, aerospace, precision machinery, and instruments. It is also used in the automobile and other industries.

The rubber industry is an important application field for calcium carbonate. From a global or local view, calcium carbonate is the most widely used filler in the rubber industry. Since the 21st century, rubber products worldwide have used about 1,500 inorganic fillers. The fillers weigh 10,000 tons. Calcium carbonate makes up about 70% of the fillers. It’s favored over other fillers due to its unique advantages. Its use is over 10 million tons.

Properties of calcium carbonate

Calcium carbonate is widely used in rubber. It is no accident that the rubber industry values it. Compared to other non-metallic mineral powder materials, calcium carbonate has obvious advantages:

cheap price

Heavy or light calcium is the cheapest among non-mineral powders. They all just try to replace calcium as a rubber filler, rather than highlighting themselves. In itself, it is meaningless.

Good color, easy to color

And can make light-colored rubber products. The downside is that the color of colored rubber products is not bright enough. But, it is still okay in most cases.

Low hardness

Its Mohs hardness is 3, which is far lower than the hardness of steel. Steel is used in making and processing of machinery and molds. So, the filled rubber harms the equipment parts (screws, barrels, etc.) and the molds it touches. Light wear.

Good thermal and chemical stability

The thermal decomposition temperature of calcium carbonate is above 800°C. It will not occur at rubber processing temperatures, which are below 300°C. Calcium carbonate is a strong base and weak acid salt. It has good chemical stability, except when encountering acidic media.

Easy to dry, no crystal water, and the adsorbed moisture is easily removed by heating.

Non-toxic, non-irritating, and odorless.

In particular, my country is rich in calcite, marble, and limestone. It has many options to choose from. Most of the resources are excellent. The heavy metal content is extremely low. It meets the national health-level requirements.

How to choose good calcium carbonate?

After you understand calcium carbonate and its effect on filled rubber, it is easy to state the basic requirements for calcium carbonate used in rubber.

1. The calcium carbonate content should be high. Silicon, iron, and other elements should be as low as possible. The levels of harmful heavy metals should be even lower.

2. The whiteness should be as high as possible. Whether it is heavy calcium or light calcium, its whiteness mainly depends on the resource. For rubber, whiteness does not affect its properties or processing. But high whiteness make people feel good. High melanin gives a competitive advantage for the same performance.

3. The lower the oil absorption value, the better. 100g of powder can absorb a maximum of some amount of butylene phthalate (DBP). This amount is called the oil absorption value of the material.

Some rubber products, like soft PVC and artificial leather, need plasticizers. This is also true for cable materials. Calcium carbonate’s oil absorption value is higher. This makes it easier to absorb the plasticizer into the filler. This absorption causes the filler to lose the properties of plasticized rubber. To achieve some softness, we need to use more plasticizers. This will raise costs. By coating the surface of calcium carbonate and reducing its particles, we can reduce its oil absorption. For example, the absorption of treated light calcium carbonate oil can be reduced. It goes from 92.91g/100g to 49.33g/100g.

4. The fineness should be right, not “finer is better.” The particle size should also fit the needs.

5. Activation or non-activation should be determined according to the needs of downstream users.

An in-depth comparison of the practicality of heavy calcium and light calcium

Calcium carbonate lowers the cost of rubber. It also improves some rubber properties. Different types of calcium carbonate can greatly improve rubber when used right. But, light and heavy calcium carbonate have puzzled most users. So, this time we will understand and tell them apart in depth.

Different sources

Light calcium carbonate is chemically synthesized. It is also called precipitated, colloidal, or activated calcium carbonate. It can even produce nano calcium carbonate, referred to as light calcium carbonate. It is made by heating limestone to make lime and carbon dioxide. Then, water is added to digest the lime and make lime milk. Its main component is calcium hydroxide. We add carbon dioxide to lime milk. This carbonizes it and makes calcium carbonate form. It is made by dehydration, drying, and crushing, or it is made from sodium carbonate. It reacts in a metathesis reaction with calcium chloride. This forms a calcium carbonate precipitate. We get it by dehydrating, drying, and crushing. We make heavy calcium carbonate by crushing natural materials like calcite, marble, chalk, and shells. We use machines. It’s also called heavy calcium.

Different packing densities

The main difference between heavy and light calcium is their different packing density. Heavy calcium products have a higher packing density, usually 0.8~1.3g/cm³. Light calcium products have a lower packing density, mostly 0.5~0.7 g/cm³. Some nano calcium carbonate products have an even lower density, about 0.28g/cm³. You can also roughly tell heavy and light calcium apart by their packaging volume. Heavy calcium products are mostly 25kg/pack and are small. Light calcium products of the same quality are larger. Some nano calcium carbonate is also 15kg per bag or 20kg per bag.

Traditionally, we often use the sedimentation volume to measure the density of calcium carbonate. The sedimentation volume is the volume of a unit mass of calcium carbonate (ml). It is measured after oscillating it in 100 ml of water for 3 hours. The larger the sedimentation volume, the smaller the particle size and density of the product. The lighter, the higher the product grade. Heavy calcium carbonate has a sedimentation volume of 1.1-1.4ml/g. Light calcium carbonate has 2.4-2.8ml/g, and nano-light calcium carbonate is 3.0-4.0ml/g. The sedimentation volume shows the difference at first. It is light calcium carbonate, heavy calcium carbonate, and nano calcium carbonate.

In fact, the densities of heavy and light calcium composite products are not much different. Generally, the real density of heavy calcium is 2.6-2.9 g/cm³, while that of light calcium is 2.4-2.6 g/cm³. Some people say that the real density of the two is the same, but the packing density is different. The reason is that light calcium particles are spindle-shaped or date stone-shaped. They take up a large volume. In contrast, heavy calcium is mostly lumpy and takes up a small volume.

Different whiteness sizes

Heavy calcium products have more impurities. So, their whiteness is usually 89% to 93%. Very a few reach 95%. Light calcium products are made through chemical synthesis and have removed many impurities. The product purity is very high, so the whiteness is mostly 92% to 95%, and some products can reach 96% to 97%. This is why light calcium products are mostly used in high-end products. The main reason for producing light-colored products is…

Moisture content varies

The moisture content of heavy calcium products is generally 0.2% to 0.3%. The moisture content is relatively low and relatively stable. The moisture content of some high-end heavy calcium products can even reach about 0.1%. Regular light calcium products have 0.3% to 0.8% moisture. This level can fluctuate and is unstable. Traditionally, the distinction between heavy and light calcium is to test the moisture with a meter. If the moisture is close to 1%, it is light calcium, and if the moisture is less than 0.1%, it is heavy calcium.

Particle size is different

Heavy calcium products have particles ranging from 0.5 to 45 microns. The particle size varies based on the crushing equipment. The particle size of ordinary light calcium products is generally 0.5 to 15 microns. The particle shape is spindle-shaped. It is hard to accurately measure and is generally a range. The nano calcium carbonate particles in light calcium are finer. Their size is usually 20 to 200nm. Ordinary light calcium carbonate has a particle size of about 2500 mesh. This size meets the needs of PVC pipes and profiles. So, considering the particle size. Light calcium carbonate is traditionally used for PVC pipes and profiles. In the past, crushing equipment was too limited. It could not crush heavy calcium carbonate to this fineness. The particle size of heavy calcium carbonate is now sufficient. It is even finer than light calcium carbonate. Therefore, both PVC pipes and profiles can now be used. .

taste different

Light calcium is usually whiter and purer. This is because impurities are removed after limestone is heated. But, many domestic light calciums have incomplete reactions. They also have a residual lime taste. If used in the food industry, like filling biscuits, it will choke but not weigh much. Also, too much calcium oxide will make the product too alkaline in water. This will also prevent adjusting the pH well, leading to unstable products.

In addition, the phosphoric acid content of the two is different. Sometimes, we need to add a bit of phosphoric acid to light calcium. This adjusts the pH to a good range. Heavy calcium does not need this.

Particle shapes are different

Viewed with a high-power microscope, ordinary light calcium particles are relatively regular. They are usually spindle-shaped when fully dispersed, as shown in Figure 2. Light calcium carbonate has synthetic particles. We can control their shape. We can add control agents during carbonization to achieve control.

Control agents now include inorganic acids and bases. They also include organic acids (amino acids), alcohols, sugars, proteins, and special biopolymers. An example is dual hydrophilic block polymers PEG-b-PMAA at different concentrations. Carbonic acid has appearances like rhombus, peanut, long rod, sphere, and dumbbell. Each appears at a different pH value. Another example is dendritic polymer polyaspartic acid. It can make spiral-shaped carbonic acid. Another example is adding an ions. Dextran can obtain spherical calcium carbonate.

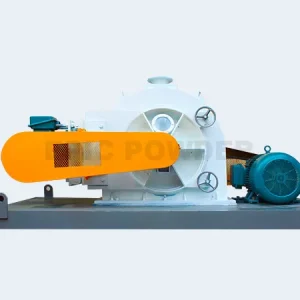

Heavy calcium products are mechanically crushed and classified. The particles have irregular shapes, such as cubes, polygons, and cuboids, as shown in Figure 1. Different methods process heavy calcium. The shapes of calcium carbonate vary under different methods. For example, calcium carbonate processed by a ramming mill is spindle-shaped. Calcium carbonate processed by an air-flow mill is granular.

Heavy calcium carbonate has a fixed crystal form. Crush and refinement will not change it. The form is the same for calcium carbonate from different sources. Generally, calcite is heavy calcium. It has a hexagonal crystal form. Marble, which is heavy calcium, has a cubic crystal form. The carbonization process creates three crystal formations of light calcium carbonate. They appear in equal amounts at different times. To obtain a single, pure crystal form, you must control the molding process.

The three crystal forms of light calcium carbonate are introduced as follows:

(1) Calcite crystal form

The hexagonal crystal system is the most stable form of calcium carbonate crystal. Under normal conditions, the mineral calcium carbonate exists in this crystal form. This crystal form of calcium carbonate has a great hiding power. It is highly white, pure, and heat and corrosion resistance. It is also chemically stable.

(2) Aragonite crystal form

Calcium carbonate is an unstable crystal form at room temperature. It belongs to the orthorhombic crystal system. This crystal form of calcium carbonate has a high aspect ratio. It is often used in polymer composites.

(3) Vitreous crystal form

This form of calcium carbonate is the most unstable crystal form. It only exists in small amounts in organic materials. It will automatically turn into calcite or aragonite crystals soon. Calcium carbonate crystals in this form are harmful to the life and health of living things. Research has shown that they play a key role. This is true for both dendritic polymer dielectrics. This is also true for certain low molecular weight polymer dielectrics. They can promote the formation of stable vaterite crystal forms.

Different oil absorption values

The absorption value of light calcium carbonate oil is 60-90 ml/100mg. This is much higher than 40-60 ml/100mg of heavy calcium carbonate. Therefore, it has good liquid absorption and rubber absorption properties. If the formula contains liquid additives, use oil absorption. Heavy carbonic acid is light , while inorganic powder is heavy. But, they both increase the needed amount of coupling agent. For example, the absorption of calcium carbonate oil increases from 40 to 50 ml/100mg. This will result in a 30% increase in the dosage of the coupling agent. Choose light carbonic acid in the PVC formula. You will use more liquid additives and PVC rubber. So, considering the oil absorption value. Opt for calcium carbonate with a low one.

Different liquidity

From a fluidity perspective, light calcium carbonate has a spindle-shaped microstructure. It has a high oil absorption value. It has components that promote flow, like lubricants, plasticizers, coupling agents, and dispersants. But, it is less fluid than heavy calcium carbonate as it absorbs. Generally, adding more than 25 parts will seriously affect the fluidity. Heavy calcium carbonate is granular and can promote fluidity. The added amount is not limited. In the PVC pipe formula, if you need more than 25 parts of calcium carbonate, use heavy calcium carbonate. It is best for fluidity.

Prices are different

Heavy calcium carbonate is mainly processed by crushing and grinding. Light calcium carbonate is made by a chemical reaction and precipitation. The latter process is much more complicated. Its requirements are much stricter. So, heavy calcium carbonate costs 30% less. It has the same particle size as light calcium carbonate. If performance allows, it is cheaper to choose heavy calcium carbonate. It is also more economical.

Different modification functions

There are subtle differences between heavy and light calcium carbonate. They have varying impacts on modification. Heavy calcium carbonate is better for tensile strength. Light calcium carbonate is better for impact strength and rigidity. Generally, the rubber surface using light calcium carbonate is smoother. And the density will be lower. Heavy calcium rubber flows better and performs better with smaller particles.

Different shade controllability

Hue is the main hue of a color, while chromatic light is the afterglow of a color. Different calcium carbonates have different colors, including white, red, cyan, and yellow. The reason is that their crystal forms are different. Powders made from different crystal forms have different hues. Calcium carbonate has three different crystal forms. type, and therefore have different hues.

The background color of heavy calcium carbonate varies by origin. Crush and refinement will not change it. For example, Sichuan calcium carbonate has a blue background. Guangxi calcium carbonate has a red background. Jiangxi calcium carbonate has a cyan background, and so on. Light calcium carbonate is made artificially by chemical synthesis. Its crystal form can be controlled during synthesis. This means its color can be controlled.

In specific color matching, calcium carbonate should match the main colorant. For example, blue calcium carbonate will cancel out the yellow pigments’ color. Calcium carbonate with blue light is also common. It is used to remove yellow light from products. Light calcium carbonate has blue light. We generally use it to add it to PVC products to eliminate the yellow light of itself. This is one reason why PVC was used to add light calcium carbonate. They chose it instead of heavy calcium carbonate.

Different pH values

Light calcium carbonate has a pH of 9-10. Heavy calcium carbonate has a pH of 8-9. So, the alkalinity of light calcium carbonate is stronger than that of heavy calcium carbonate. When calcium carbonate burns, it’s easier to absorb acidic gases from its products. So, burning calcium carbonate composite products creates little toxic gas. This is because calcium carbonate is alkaline. It can absorb acidic gases like HCl and H2S made by combustion. This eliminates the risk of dioxins made when acidic substances with chlorine.

Only calcium carbonate is filled with inorganic substances. It can reduce the calorific value when burned. When burned, it turns to powder. It doesn’t drip oil or black smoke, causing no extra pollution. It doesn’t damage the incinerator. This is in line with the trend of eco-friendly products.

So, burning calcium carbonate composite products releases little poisonous gas. Light calcium carbonate is the first choice. It is more environmentally friendly and has a large social impact.

This is important. We must tell apart light and heavy calcium carbonate. Choosing the right calcium carbonate for your formulas is crucial. This way, you can select materials as needed. They can meet the performance and cut costs.

Effect of “Alkalinity” of Calcium Carbonate

Calcium carbonate is widely used as a filler in the rubber production process. However, rubber manufacturers have problems with their products. These include yellowing and brittleness to varying degrees. Today, the editor will primarily focus on how calcium carbonate alkalinity affects rubber. It causes brittle and yellowing. Alkalinity is often a factor that many makers ignore.

The alkalinity of industrial precipitated calcium carbonate is the free base. This is caused by some reason during our production. Free base is the substance in making calcium carbonate. It is not converted into calcium carbonate, but exists as calcium hydroxide. If the alkalinity is too high, it will react with other plasticizers in the plastic. This will make plastic brittle and yellow. Free alkali is an important technical indicator of calcium carbonate. It must be strictly controlled in production.

The main reason for the high alkalinity of calcium carbonate is the formation of basic calcium carbonate.

Overburning of lime

During lime calcination, lumps are different sizes. Poor control makes it easy to over-burn the lime. Over-burned lime needs a lot of water to digest. The water is cold, so digestion is incomplete. This creates lime particles. During carbonization, calcium carbonate uses fine particles as crystal nuclei. It is deposited on them to form a coating on calcium oxide particles. We know that calcium oxide crystals are cubes. Calcium carbonate crystals are rhombohedral. The intergranular angles of these two crystals differ. They have different expansion coefficients after heating. This causes crystal grains to break and releases calcium oxide. Appearing alkaline.

High free base

Basic calcium carbonate is especially insoluble in cold weather. This is because low temperatures make calcium hydroxide very soluble. During carbonization, solid calcium hydroxide and water-soluble ions are present in lime milk. They react with carbon dioxide to carbonize. Occurs in an alkaline solution, thus producing basic calcium carbonate. This simple calcium carbonate changes with the temperature of the carbonization liquid. This also changes with the amount of added carbon dioxide. It transforms into three types of calcium carbonate: calcite, spirit stone, and aragonite. Upon carbonization, the pH is between 8 to 10. This pH is alkaline and basic calcium carbonate cannot be destroyed. These basic calcium carbonates have not had time to change and enter the next process. When you enter the rotary dryer, the temperature rises. Heat makes the basic calcium carbonate into calcium hydroxide and carbon dioxide. This process makes the alkalinity.

High alkalinity is more prominent in cold weather than hot weather. The key is that hot weather has high temperatures and water temperatures. They digest lime better. At the same time, the tower is hot and calcium hydroxide is not soluble. Making a plate-like basic carbonic acid is difficult. Calcium is easily converted into calcium carbonate. It can be seen that the alkalinity is lower in hot weather than in cold weather.

So, when processing rubber products, note the particle size. Also, note the whiteness, moisture, and sedimentation volume. You must also note the mineral elements in calcium carbonate. Please check the calcium carbonate’s alkalinity as well.