Pigments and fillers have a basic job. It is to give the coating a certain color. They also add hiding power, chemical resistance, and other properties. Inorganic fillers, also called body pigments, do not have the tinting and hiding ability of coloring pigments. This is because their refractive index is like that of film-forming substances. However, they can thicken the coating by filling it. They also play a skeleton role in the coating. They make the coating full and thick. This reduces the cost of coating production.

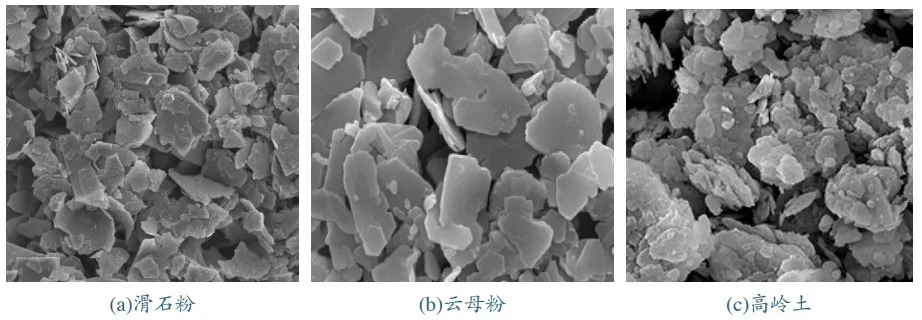

In coating applications, fillers fall into five types. They are: carbonates, silicates, silicon dioxide, barium sulfate, and aluminum hydroxide. This division is based on their mineralogical and basic chemical differences. Among them, silicate mineral fillers are widely used in coatings. Their effects have advantages over carbonate mineral fillers. Common fillers include talcum powder, mica powder, kaolin, and feldspar powder. They also include wollastonite and others.

5 types of common silicate coatings

Mica powder

Mica powder is a silicate containing Al and Mg. Mica ore is ground into fine powder after drying or wet grinding. The impurities are removed, filtered, and dried to make a flaky, fine powder. Its appearance is a silvery white to gray color. Adding this flaky powder to latex paint can increase the coating’s crack resistance.

Its horizontal layout in the paint can blocks ultraviolet radiation. This protects the coating and stops moisture. It is chemically stable. It can improve the coating’s heat and weather resistance. It can dampen, insulate, and absorb shock. It can also improve the coating’s strength, resistance to becoming powder, and durability. It can be used for damping paint, fire retardant paint, and exterior wall latex paint.

Basic application indicators and performance

Particle size: 325~500 mesh.

Performance: Give the coating film flexibility, water resistance, and weather resistance; enhance the coating’s chemical resistance, heat resistance, and electrical insulation, etc.

Reference dosage: 5-10%.

Wollastonite

Wollastonite is a calcium silicate. It has a needle-like structure. It comes in two types: natural and synthetic. The natural white powder used in the paint industry is wollastonite, an alkaline pigment with a pH of 9.9.

People use natural woolastonite as a buffer in vinyl acetate latex paint. It prevents the pH from becoming too alkaline. Due to its low oil absorption, it is also common in oil-based paints. Synthetic wollastonite is mainly used in interior wall matte paints. It has a certain degree of opacity, can improve wet abrasion resistance, and has a higher matte effect.

Basic application indicators and performance

Particle size: 325-1250 mesh.

Performance: Maintain the smoothness and glossiness of the coating surface; enhance the mechanical strength, durability, adhesion, corrosion resistance and other properties of the coating.

Reference dosage: 10% to 40%.

Kaolin

Kaolin is also known as hydrated aluminum silicate, porcelain clay, and white clay. Its chemical formula is AL2O3·2SiO2·2H2O. This natural product often contains quartz, feldspar, and mica. It looks like white powder and feels soft. Using it in latex paint can improve suspension and prevents pigment sedimentation. It can also make the coating film harder. But, it absorbs a lot of water.

Kaolin adds the viscosity of the coating. This helps prevent sagging and aids storage stability. It also boosts the film’s hiding power. Also, filler can improve the film’s bending strength and internal stress. It can also stop the film from cracking due to bending or expansion of the base.

Basic application indicators and performance

Granularity: 600-1250 mesh.

Basic performance: Enhance the light resistance, acid and alkali resistance, and anti-settling of the coating.

Reference dosage: 5%-20%.

Talc

Talc is a natural product with a molecular formula of 3MgO·4SiO2·H2O and a white powder appearance. The particle form of talc is divided into two types: flake and fibrous. Flake talc is better than fibrous talc for water and moisture resistance.

Talc is not easy to sink in the paint, and can suspend other pigments, and can also prevent the paint from sagging. It can absorb stretching stress in the coating to avoid cracks and gaps. So, talc is good for outdoor paint. It is also good for washable, wear-resistant paint.

Basic application indicators and performance

Granularity: 325-1250 mesh.

Basic performance: increase coating adhesion, lubricity, corrosion resistance, water resistance, and anti-settling.

Reference dosage: 10%~15%.

Feldspar powder

Feldspar powder is a typical mineral filler with a framework structure. Feldspar powder comes in three forms. The form depends on the cation: sodium, potassium, or calcium. Feldspar powder is composed of angular nodular particles. Compared to spherical or ordinary block fillers, it can form a denser coating. It gives the coating high wear and scratch resistance. This also improves the coating’s anti-corrosion performance.

Basic application indicators and performance

800 mesh~1250 mesh.

Basic performance: wear resistance, anti-corrosion.

Reference dosage: 5%~20%.

Coating technology is always improving. So, the parts of coatings need to perform better. Inorganic fillers serve as a skeleton for coating. They also affect its properties. So, ultrafine powder tech and powder modification will be important for deeply processing fillers. It will be key to the development of coating products for a long time.