Marble and limestone are two of the most used natural stones in construction and design. Both can be used to produce calcium carbonate powder. Marble, formed from limestone under heat and pressure, is prized for its beauty and strength. This metamorphic rock is often used in high-end applications. These include countertops, sculptures, and flooring. It has a wide variety of colors and patterns that make each piece unique.

The appearance of things hides the inner differences. As the saying goes in polymer physics, structure determines performance. In-depth, a structure’s chemical properties determine its outer properties.

These ores go from ore to powder. This involves breaking the ground ore. Then, grinding it using methods like dry and wet grinding and equipment like rollers or balls. In other words, the ore is broken from a large piece into a powder of a certain size. This is done with the help of grinding processes and equipment.

These force processes leave special traces on the ore powder.

The powder’s surface structure is very different. Each structure corresponds to different chemical groups. So, their physical and chemical properties are different.

After talking about the theory, let’s talk about the actual performance:

Limestone

It is a completely uncleaved rock. It is a type of sedimentary rock with low whiteness, high hardness, and high density. It is good for making sand and gravel. Also, it is used for putty powder. It is also used for desulfurization coarse powder for power plants. And, it is used for making quicklime. It is used for other high viscosity or low value applications. This is because the surface cations of limestone powder cause the vast majority. Its oil absorption value is low. But, there are too many side effects, like powder clumping and viscosity increase. PVC wallboards have problems. These include strong PVC decay. Also, high melt viscosity, poor flow stability, and low extrusion efficiency. And, serious screw corrosion. To cover up these problems, they add more lubrication. But, this will reduce the product’s performance.

Even if used on yellow foam board, the life of the screw will be shortened to 1/3 of the original.

In summary, the powder is cheap but inefficient. The equipment wear is high but the qualified rate is low. The production consumables are expensive and reduce product performance. The overall cost is high.

Marble

It is formed by the metamorphism of sedimentary rocks. Different bedrocks and conditions make many crystal varieties. There are microcrystals and coarse crystals. Most are moderately hard and incompletely cleaved ores. This cleavage leads to the coexistence of anions and cations on the surface of the powder.

Various cleaved ores have a great impact on performance.

Unlike limestone powder, the powder flows better and is less abrasive. It also significantly lowers PVC melt viscosity. This improves extrusion efficiency and reduces PVC degradation. It also improves the product’s mechanical properties.

Conclusion: There are many types. The differences are huge. Powder is expensive. But, the overall experience is good. And the total cost is low.

Large calcite

In theory, this type of filling ore is completely cleaved. In fact, from the SEM pictures, there are still many powders that are not completely cleaved. In general, the surface of this type of powder is mainly anionic, which helps flowability.

In theory, this type of ore powder should be easy to use. However, some large calcites are from the chicken nest mines. These mines are in caves and have many impurities. The calcites need to be washed and selected, and their moisture is hard to control. The cost is also high.

The limit of anionic powder is that it is incompatible with resin, such as graphite. If you want to help flowability and porosity, then this type of product is very good, such as breathable film. But if you want high mechanical properties, then you need to consider it carefully.

Raw materials influence PVC products. This includes transportation, feeding, pre-plasticization, flow, and compatibility. We need to consider this influence in full.

Understand the ore, equipment, and process. Select the right powder and make the right product.

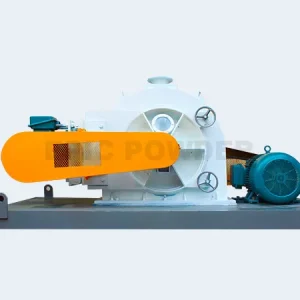

Marble and limestone grinding production line related equipment

Qingdao Epic Powder Machinery Co., Ltd. is a professional powder equipment manufacturer. The products include: jet mills, ball mill, air classifiers and modifiers. Surface coating equipment from Qingdao Epic includes: pin- mill modifier, turbo- mill modifier, three-roller modifier and multi-rotor -mill modifier.

If you have any related needs or questions, please contact Qingdao Epic directly.