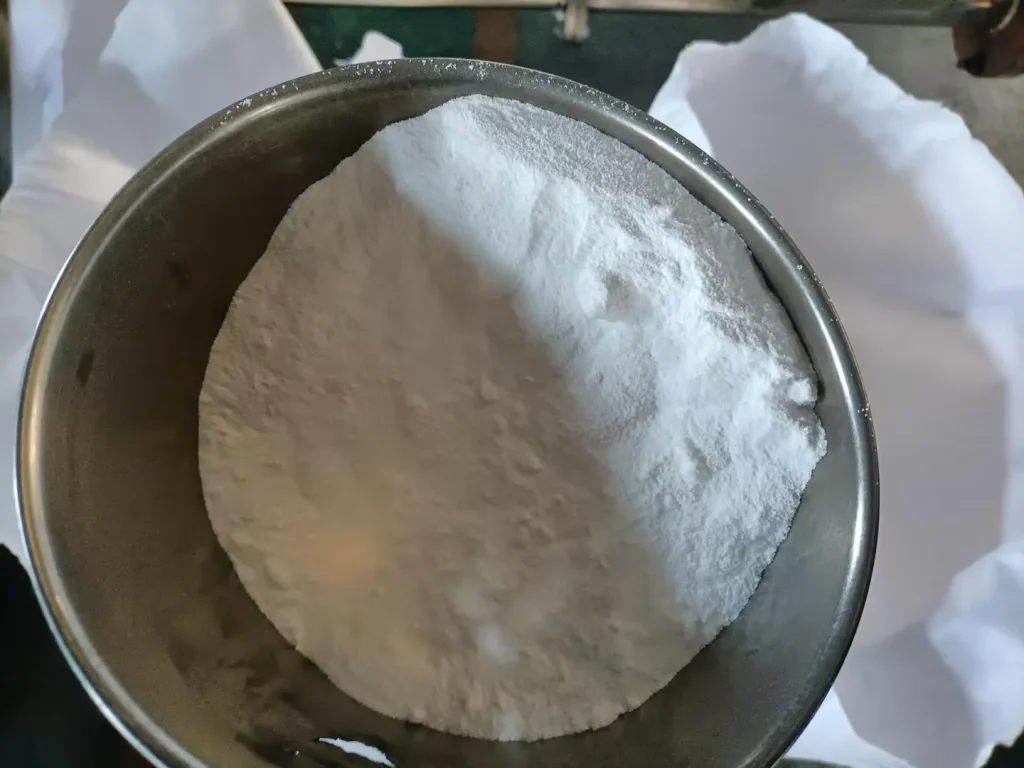

Sodium carbonate, or soda ash or washing soda, is a white, crystalline solid compound with the chemical formula Na2CO3. It is an alkaline substance commonly used in industrial and domestic applications.

What Is Sodium Carbonate?

Sodium carbonate is derived from sodium chloride (common salt) and limestone through the Solvay process. It primarily produces glass, detergents, soaps, and paper. It is also used in water treatment, as a pH regulator, and in manufacturing chemicals, textiles, and food products.

In addition to its industrial uses, sodium carbonate is used in households as a cleaning agent, particularly for removing tough stains, and as a water softener. It can also be used as a food additive, buffering and enhancing the texture of certain food products.

Sodium carbonate is a relatively safe compound when used in appropriate quantities. However, it can be harmful if ingested or exposed to the skin or eyes in high concentrations.

What is sodium carbonate is used for?

Sodium carbonate, also known as soda ash or washing soda, has various uses, including:

- Cleaning agent: It is commonly used as a cleaning agent in household products such as detergents, dishwashing soaps, and laundry detergents due to its alkaline nature and ability to remove grease and stains.

- Water treatment: Sodium carbonate is used in water treatment processes to adjust pH levels and remove impurities, such as heavy metals and chlorine, from water.

- Glass manufacturing: It is a key ingredient in the production of glass, as it helps to lower the melting point of silica and improve the transparency and durability of the glass.

- pH regulator: Sodium carbonate is used as a pH regulator in various industries, including food and beverages, cosmetics, and pharmaceuticals, to adjust the acidity or alkalinity of products.

- Paper production: It is used in the paper industry as a bleaching agent to control pH levels during manufacturing.

- Dyeing and textile industry: Sodium carbonate is used in dyeing processes to fix and enhance the colour of fabrics.

- Food additive: It is approved as a food additive (E500) and is used in some food products as a leavening agent, pH regulator, or firming agent.

- Pool maintenance: Sodium carbonate is sometimes used to raise the pH levels in swimming pools and maintain proper water chemistry.

- pH buffering agent: It is used in various laboratory applications as a pH buffering agent, helping to maintain a stable pH level in chemical reactions.

- Fire extinguisher: Sodium carbonate can be used as a fire extinguishing agent for certain types of fires, particularly those involving flammable liquids or electrical equipment.

How to produce sodium carbonate ultrafine powder?

To produce sodium carbonate ultrafine powder, you can follow these steps:

1. Obtain high-purity sodium carbonate. You can purchase it commercially or prepare it by heating sodium bicarbonate (baking soda) at a high temperature.

2. Grind the sodium carbonate into a fine powder using a mortar, pestle, or mechanical grinder. This will break down any larger particles and create a more uniform powder.

3. Dissolve the sodium carbonate in water to create a saturated solution. This means adding enough water to dissolve the sodium carbonate completely but not adding any excess water.

4. Filter the saturated solution using filter paper or a fine mesh sieve to remove insoluble impurities.

5. Transfer the filtered solution to a container and let it evaporate slowly. This can be done by leaving the container uncovered in a controlled environment with low humidity.

6. As the water evaporates, sodium carbonate crystals will form. These crystals will be larger and more pure than the original sodium carbonate powder.

7. Once the solution has completely evaporated, collect the sodium carbonate crystals and allow them to dry thoroughly.

8. Grind the sodium carbonate crystals into an ultrafine powder using a mortar, pestle, or mechanical grinder. This will further break the crystals into smaller particles, producing finer powder.

9. Store the sodium carbonate ultrafine powder in an airtight container to prevent moisture absorption and maintain its quality.

Note: It is important to wear appropriate safety gear, such as gloves and goggles when handling chemicals. Follow all safety precautions and guidelines provided by the manufacturer.

What equipment can produce D50: 3μm sodium carbonate fine powder?

It is important to note that the specific equipment used may depend on factors such as production capacity, desired particle size distribution, and process requirements. Consulting with experts or equipment manufacturers in the field can help determine the most suitable equipment for producing D50: 3μm sodium carbonate fine powder.

Let’s check out the video below to understand the ultra-fine grinding of sodium carbonate fine powder.