The sand mill works by stirring together the grinding medium and the material. This is done by the high-speed rotating dispersion disc in a fixed cylinder. It causes strong shearing, scraping, and collisions. They are between the solid particles and the grinding medium. This achieves crushing, grinding, and dispersion. Sand mills can be divided into vertical and horizontal types. This division is based on their structures. What are the advantages of a sand mill? How do they compare to other ultra-fine grinding gear? The editor of China Powder Network tried to find the answer. They did so through the following experiment.

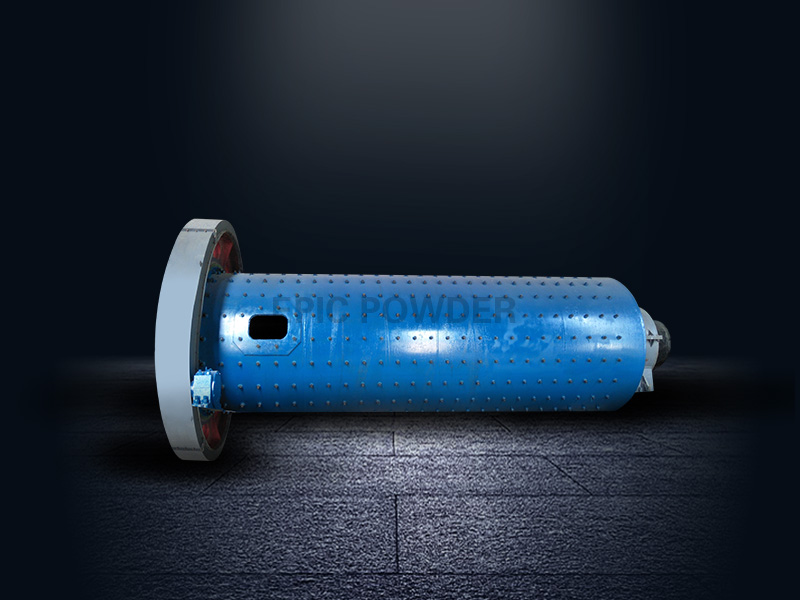

Sand mill VS ball mill

Many researchers have done many experiments. They studied the grinding efficiency of ball mills and sand mills. The results show that sand mills are superior to ball mills. They are better in terms of grinding efficiency and cost to prepare. Also, the experiment showed that the sand mill can produce powder with an average particle size of under 0.5 μm. This size is much smaller than the size of the powder produced by the ball mill.

Experiment 1: Crushing Processing of Piezoelectric Ceramic Materials

We studied how different crushing equipment affects the size and distribution of powder. In the experiment, the researchers put 3kg of piezoelectric ceramic into a ball mill. They put some in the vibrating grinding hopper and some into the sand mill bucket for crushing. All were processed using the wet method. Samples were taken regularly to measure the particle size and its spread. This was done to compare the time needed by the three types of equipment to process the powder. The comparison was when the powder particle size D50 reaches about 0.5 μm.

| Equipment | Processing time (h) | D10 | D25 | D50 | D75 | D90 |

| Ball mill | 16 | 0.31 | 0.49 | 0.71 | 2.38 | 4.28 |

| Vibration mill | 4 | 0.29 | 0.42 | 0.58 | 1.75 | 2.88 |

| Sand mill | 1.25 | 0.19 | 0.33 | 0.46 | 0.58 | 0.77 |

The results show that vibration grinding is better than ball grinding. It’s better for crushing and for particle size. Sand grinding is much better than ball milling and vibration grinding. This is about the size of the crushing balls. It is also about the speed and energy of the balls. Smaller balls grind better. They make finer powder with a narrow size range.

In the experiment, the ball used for sanding was 1.5mm (1.5Kg). The balls for milling and grinding were a mix of 20mm, 15mm, and 8mm (7.5Kg). Sanding has a much larger working surface than ball milling and vibrating grinding. The ball’s speed is 1800 rpm when sand is grinding. It’s 600 times/min when vibrating grinding. And it’s 65 rpm when ball grinding. So, the sand grinding process is the most efficient at crushing. It makes the finest powder with the narrowest range of particle sizes. It also makes the highest quality crushes.

Based on the test results, Cai Gaogong concluded something. He concluded that using a sand mill to crush piezoelectric ceramics is better. It improves the microstructure, mechanical, and dielectric properties of ceramics. These transducers reduce the performance decay by 50%. It also extends their life from 5,000 hours to 8,000 hours.

Experiment 2: Crushing and processing of lithium battery materials

Kangtuo compared the size of LiFePO4 made by two methods. One method was traditional high-energy ball milling. The other method was the sand grinding-spray drying. Kangtuo found that the precursor made by ball milling is 300-400nm after sintering. Its particle size range is wide. , and the particle morphology is different, with no obvious similarities. The sand grinding-spray drying method transforms LiFePO4 precursor. It has a particle size of less than 100 nm and has a narrow size distribution. There is no spray drying and sintering. The product is spray-dried and sintered. Then, it is agglomerated into microspheres with a diameter of about 10 μm. Amplifying the microspheres reveals that they are made of many spindle-shaped particles. The particles are small and the sizes are uniform. is about 300nm.

The LiFePO4 precursor’s peak shape was made through sand grinding. It was then dried using spray-drying. It is prominent and sharp. This shows that LiFePO4 made this way is more crystalline. This is because the sand mill spins at 2800 rpm during grinding and mixing. The high-energy ball mill spins at only 1200r/min. Also, the diameter of the zirconia ceramic beads in the sand mill is only 0.3mm. The speed of the ball mill is also 0.3mm. The diameter of the internal steel balls is 2mm. So, sand mills can grind materials to finer sizes and mix them better than high-energy ball mills. This increases the degree of reaction and crystallinity.

LiFePO4/C materials made by sand grinding-spray drying are better. They are better than those made by ball milling and simpler. This simplifies the synthesis process.

Sand mill PK jet mill

The study pointed out that sand mills have advantages. Compared to other grinding equipment, such as airflow mills. They have high fineness, strong continuity, and high efficiency. The fineness requirements can be changed. You can do this by adjusting the right amount of grinding media. Or, grinding with various media can be done. The sand mill’s grinding medium moves at a high speed. Its grinding effect comes mainly due to impact and shearing forces. The zirconia bead grinding media used in the experiment causes no pollution. It does not pollute the raw materials. It is small in size and has many connections. It can do ultra-fine grinding and dispersion.

The raw materials are ground in a high-speed grinder. The liquid phase is evenly mixed and fully reacted to obtain a slurry. Then, through the spray dryer, the slurry is atomized and in contact with hot air. The water quickly vaporizes. During this process, the slurry is processed and dried. This process obtains lithium battery electrode materials.

Sand mill + ball mill + jet mill combination

The sand mill has some unmatched advantages in dispersion and grinding. But, EPIC Powderxiao’bian also acknowledges its own limits. For example, the fineness of raw materials can be refined. The sand mill size requirements are generally less than 80 mesh (<0.18mm). Also, the sand mills used in the coating industry are smaller. One single product cannot sustain the ceramic industry.

We see the use of ball mills, jet mills, and sand mills in the processing of various materials. This includes the experiments in this article. Some researchers use a combination of ball mills and stirrer sand mills for grinding. In batch mode, the grinding time is much shorter. Grinding is also more efficient and uses less power. In some processes, the materials are first stirred by a ball mill. Then, they are ground with a sand mill. In other processes, the material is ground with a sand mill first. Then, the sintered material is crushed with an airflow mill. The three cooperate. They perform their duties. This achieves the best processing and material performance.