As the food industry evolves, grinding technology becomes increasingly crucial. It affects food quality, taste, nutrition, and efficiency. Consumers demand diverse, refined, and nutritious food. This drives innovation in food grinding technology. The moinho classificador de ar in food grinding stands out as an innovative solution. Its unique mechanism boosts food processing capabilities significantly.

Working Principle of Air Classifier Mill

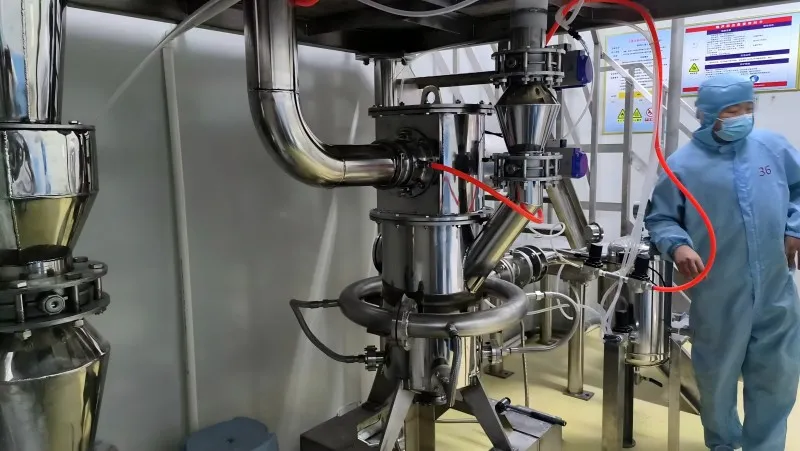

The mill operates through high-speed impact and precise classification. A motor drives the fast-rotating body like blades or hammers. Food materials enter and get hit violently in the grinding chamber. Particles collide with rotating parts, each other, and the chamber wall. This multi-force action achieves initial food particle crushing. Ground particles move with airflow into the classification zone. A precision classifier, like a wheel, sorts particles by size and weight. Oversized particles are rejected and re-ground in the chamber. Qualified fine powder exits with airflow, completing the process. This integrated system ensures consistent and fine powder output.

Advantages of Air Classifier Mill in Food Grinding

Controle preciso do tamanho das partículas

The mill produces powders as fine as micron or submicron level. It allows flexible control over final tamanho da partícula. In chocolate making, fine cocoa powder improves texture and meltability. In seasoning, fine pepper dissolves well in soups and sauces. Coarse pepper enhances texture in meat marinades and steaks.

High Efficiency and Energy Saving

Compared to traditional mills, it processes more material per time. High-speed impacts enable rapid grinding with less energy loss. It’s ideal for large-scale grain grinding at lower energy costs. This reduces production expenses and boosts economic benefits.

Low Temperature Grinding and Nutrient Retention

Sensitive nutrients degrade at high temperatures during grinding. This mill shortens grinding time and removes heat via airflow. It suits fruit and vegetable powder processing, preserving vitamins. Low temperatures keep flavonoids and antioxidants active. It maintains bioactivity in plant extracts for functional foods.

Low Contamination, Ensuring Food Safety

Fully enclosed systems prevent contamination from the environment. Dust leakage is minimized, keeping the workspace clean. Food-contact parts use food-grade materials to avoid metal shavings. This ensures high hygiene for infant and health foods.

Applications in Food Grinding

Grain Processing

The mill precisely grinds wheat into various flour sizes. Coarse flour suits chewy bread; fine flour suits cakes. Whole grains like brown rice retain nutrients after grinding. They become flakes or powders for nutritious breakfast products.

Nuts and Seeds Processing

It crushes almonds, walnuts, sesame into uniform particles. For nut butters, it controls texture from smooth to crunchy. In baking, nut bits add taste and nutrition. Fine sesame powder enhances sauces like tahini and paste.

Functional Food Ingredient Preparation

It grinds fiber-rich grains or legumes into dietary fiber powder. This adds fiber to drinks, baked goods, and dairy products. For superfoods like spirulina and maca, it improves dispersion. Fine powder boosts bioavailability and health effects.

Comparison with Other Grinding Methods

Versus Traditional Mechanical Grinding

Hammer and disc mills grind with direct mechanical force. They often lack precision in controlling particle size. Wide size distribution affects product quality. They generate heat, degrading sensitive nutrients. The moinho de impacto overcomes these with fine control and low heat.

Versus Moinho a jato

Jet mills use high-speed air for ultra-fine grinding. They offer narrow size distribution but cost more to run.

The impact mill delivers similar results with lower energy needs. Jet mills struggle with hard or sticky foods. Impact mills handle diverse materials with adaptable designs.

Future Development of Air Classifier Mills in Food Grinding

Future classificador de ar mills will be more efficient and precise. Designs will improve durability and reduce maintenance. New materials and manufacturing will extend equipment life. Automation and smart control will enhance stability and safety. Sensors will monitor flow, temperature, and classifier speed. Real-time adjustments ensure consistent product quality. Demand for personalized food will drive tailored grinding solutions. More eco-friendly systems will reduce energy use and pollution. These advances support sustainable and high-quality food production.

Conclusão

The air classifier mill excels with fine control and efficiency. It preserves nutrients and ensures cleanliness in food processing. It supports traditional and modern food production needs. With continued innovation, it may become an industry standard. It will help deliver healthier, safer, and better food products.

Pó épico

Epic Powder, com mais de 20 anos de experiência na indústria de pós ultrafinos. Promovemos ativamente o desenvolvimento futuro de pós ultrafinos, com foco nos processos de britagem, moagem, classificação e modificação de pós ultrafinos. Entre em contato conosco para uma consulta gratuita e soluções personalizadas! Nossa equipe de especialistas se dedica a fornecer produtos e serviços de alta qualidade para maximizar o valor do seu processamento de pós. Epic Powder — Seu especialista confiável em processamento de pós!