How can powders improve the problem of cosmetics not being skin-friendly?

With the popularity of makeup, powder usage in cosmetics is growing. Cosmetics powders fall into four main categories. These are pigment powders, white powders, filler

Powerful vortex flow field, instantly grinding and coating

The tapered rotor and stator are adopted, and the gap between the rotor and the stator can be adjusted; the powerful vortex flow field, the linear speed of the rotor can reach 120 m/s, which is especially suitable for the dispersion, reduction and crushing of agglomerated materials. The material is impacted, sheared and rubbed at high speed between the rotor and the stator to complete the grinding and coating process.

This continuous powder surface coating system is designed on the base of German know how with Chinese equipment, and can be used for coating of various powders like calcium carbonate (GCC, PCC), kaolin, talc, mica, graphite, barium sulfate, white carbon black, magnesium hydrate, zinc oxide, aluminum oxide, and is suitable for a variety of solid/liquid coating agents, like aluminate coupling agent, titanate coupling agent, silane coupling agent and stearic acid. Coating machine consists of three units of mixing rooms. High-speed rotation creates great vortex flow inside these special-shaped rooms. Powder and coating agent are mixed in the high-speed gas-solid vortex flows. Coating machine with both surface coating and particle dispersing functions is suitable for various powders with different fineness, and has a unique coating effect for the materials with small apparent specific gravity and high volume to weight ratio. Automatic temperature control system ensures stable high temperature for coating agent melting into liquid and mixing with uncoated powder. Heating and cooling of powder and coating agent are completed in one machine, which does not need independent cooling system. High utilization ratio of coating agent, high powder-coated rate, high activation grade, low energy consumption, and very few agglomerates in final coated product. The whole system is operated under negative pressure, no dust emission, and low labor intensity.

| Model | 300 | 500 | 750 | 1000 | 1250 |

|---|---|---|---|---|---|

| Speed(m/s) | 100-120 | 100-120 | 100-120 | 100-120 | 100-120 |

| Motor Power(kw) | 22 | 45 | 75 | 110 | 132 |

| Blade(layer) | 4 | 4 | 6 | 6 | 6 |

| Fineness(mesh) | 50-2500 | 50-2500 | 50-2500 | 50-2500 | 50-2500 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

With the popularity of makeup, powder usage in cosmetics is growing. Cosmetics powders fall into four main categories. These are pigment powders, white powders, filler

In 1989, SONY discovered petroleum coke could replace lithium in rechargeable batteries. This marked the start of large-scale lithium-ion battery applications. Research on anode materials

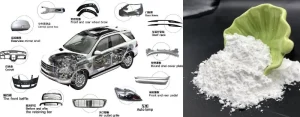

Amazing! There are so many ultrafine powder materials in automotive plastics. With the rapid development of the economy, cars have entered every household, accompanying daily

Diamond, commonly known as “diamond drill,” is a mineral composed of carbon atoms. It is an allotrope of graphite, with the chemical formula C, and

Ultrafine powder milling technology is called a cross-century high-tech by scientists worldwide. After refinement, material properties change significantly. Optical, electrical, magnetic, and mechanical properties are

White carbon black is modified silicon dioxide, which is a general term for white powdered X-ray amorphous silicic acid and silicate products. It mainly refers

Ceramic powders are the fundamental “cells” in ceramic material R&D and production. Ceramic powder preparation process directly affects the performance and quality of final ceramic

With the rapid growth of the new energy industry, lithium iron phosphate batteries have become the new favorite of the market with their advantages such

THE MACHINES WE CAN PROVIDE

CONTACT OUR TEAM

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.

© 2000-2023 Calcium Carbonate High-Value Process Expert | EPIC powder Machinery Co., Ltd. | All rights reserved | Privacy policy

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.