How can powders improve the problem of cosmetics not being skin-friendly?

With the popularity of makeup, powder usage in cosmetics is growing. Cosmetics powders fall into four main categories. These are pigment powders, white powders, filler

CTC series air classifier is designed under the guidance of our German experts, and it is specially developed for separating powder products between 32-250μm. It does not require any peripheral equipment, such as cyclone collector, bag filter, induced draft fan, etc. Raw material enters the classifier from the top and falls onto the rotating bulk pan. The bulk pan distributes the product in an adjustable airflow created by an internal fan. Fine particles are entrained in the airflow and carried to the outer chamber, while coarse particles fall into the inner chamber. Fine powder products and coarse powder products are discharged from the bottom of the classifier respectively. This process of internal air circulation and self-grading greatly reduces investment, production and maintenance costs. When processing high-hardness materials such as abrasives and quartz, the inlet chute and internal rotating parts can be made of high-hardness materials or lined with high hardness, depending on the situation. In addition, if it is necessary to avoid iron pollution, the interior of the classifier can be lined with alumina ceramic sheets and polyurethane.

CTC series air classifier is designed under the guidance of our German experts, and it is specially developed for separating powder products between 32-250μm. It does not require any peripheral equipment, such as cyclone collector, bag filter, induced draft fan, etc. Raw material enters the classifier from the top and falls onto the rotating bulk pan. The bulk pan distributes the product in an adjustable airflow created by an internal fan. Fine particles are entrained in the airflow and carried to the outer chamber, while coarse particles fall into the inner chamber. Fine powder products and coarse powder products are discharged from the bottom of the classifier respectively. This process of internal air circulation and self-grading greatly reduces investment, production and maintenance costs. When processing high-hardness materials such as abrasives and quartz, the inlet chute and internal rotating parts can be made of high-hardness materials or lined with high hardness, depending on the situation. In addition, if it is necessary to avoid iron pollution, the interior of the classifier can be lined with alumina ceramic sheets and polyurethane.

| Parameter / Model | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Drive power of internal fan(kW) | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 37 | 55-75 |

| Drive power of classifier (kW) | 2.2 | 3.0 | 4.0 | 5.5 | 7.5 | 11 | 15 | 22 |

| Max. classifier speed (rpm) | 800 | 670 | 560 | 475 | 400 | 355 | 315 | 280 |

| Max. feed rate (t/h) | 5 | 8 | 12 | 17 | 24 | 30 | 38 | 48 |

| Fineness D97 (μm) | 32-200 | 32-200 | 32-200 | 32-200 | 40-200 | 40-200 | 45-250 | 50-250 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

With the popularity of makeup, powder usage in cosmetics is growing. Cosmetics powders fall into four main categories. These are pigment powders, white powders, filler

In 1989, SONY discovered petroleum coke could replace lithium in rechargeable batteries. This marked the start of large-scale lithium-ion battery applications. Research on anode materials

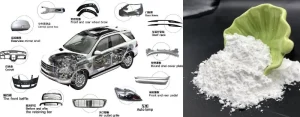

Amazing! There are so many ultrafine powder materials in automotive plastics. With the rapid development of the economy, cars have entered every household, accompanying daily

Diamond, commonly known as “diamond drill,” is a mineral composed of carbon atoms. It is an allotrope of graphite, with the chemical formula C, and

Ultrafine powder milling technology is called a cross-century high-tech by scientists worldwide. After refinement, material properties change significantly. Optical, electrical, magnetic, and mechanical properties are

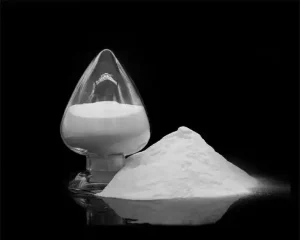

White carbon black is modified silicon dioxide, which is a general term for white powdered X-ray amorphous silicic acid and silicate products. It mainly refers

Ceramic powders are the fundamental “cells” in ceramic material R&D and production. Ceramic powder preparation process directly affects the performance and quality of final ceramic

With the rapid growth of the new energy industry, lithium iron phosphate batteries have become the new favorite of the market with their advantages such

THE MACHINES WE CAN PROVIDE

CONTACT OUR TEAM

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.

© 2000-2023 Calcium Carbonate High-Value Process Expert | EPIC powder Machinery Co., Ltd. | All rights reserved | Privacy policy

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.