What is calcium carbonate used in breathable membranes? What are the production difficulties? What is a breathable membrane? A breathable film is microporous. It lets water vapor through but obstructs liquid water. It is primarily used to make health products. It also makes breathable, rainproof cloth and other products. It is used in various fields such as medicine, health, personal care, construction, and agriculture. It is also used in sideline product packaging. It is also widely used in other fields.

Why does the breathable membrane use calcium carbonate? What kind of calcium carbonate is used?

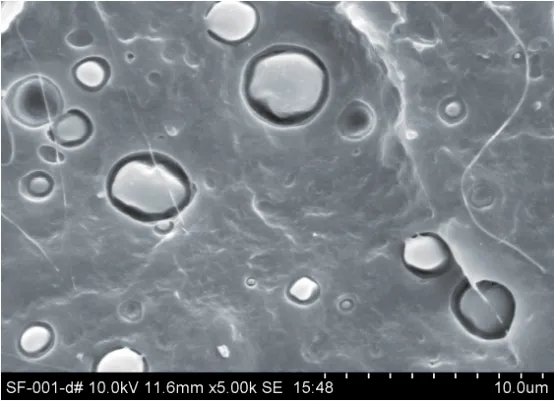

Breathable film production starts by filling polyester with inorganic fillers, mainly calcium carbonate. Then, a film is made by casting or blow molding. Finally, the film is stretched in one or two ways to stretch the polyester. This separates the surface of the calcium carbonate particles. It forms a microporous breathable membrane by creating channels between the filler particles.

In general, the D50 of calcium carbonate powder in breathable films is stable. It is 1.8-2.2 μm. The BET is 5-15 m2/g. Still, products of different companies differ. Domestic and foreign products also differ in stability. The size and distribution of calcium carbonate particles are key. They are key in creating breathable films. They directly affect fluidity of the processing material. This, in turn, sets the film’s production speed and stability. It also affects stretch, porosity, and pore structure. It also affects air permeability. It has an important impact on mechanical properties.

How to produce calcium carbonate for breathable membrane?

Companies adopt dry methods for heavy calcium carbonate. This is due to its chemical properties, production efficiency, and benefits.

What are the flaws in domestic carbonic acid companies? They are in the market, equipment, preparation processes, and products for breathable membranes.

Enterprise and market aspects:

Now, my country’s heavy calcium industry has small-scale production by enterprises. So, the industrial scale is low. Resource-intensive, extensive processing is common. This leads to a chaotic and intense competition among peers. They have low economic benefits. Also, they lack industrial equipment and technology. These problems include high energy use, small-scale, and pollution. Few large-scale processing equipment and processes save energy. And, there are few such things in development and use. Refined deep-processing equipment and technology are relatively backward. Many other reasons have led to the development of my country’s heavy calcium industry. Lags behind developed countries in terms of development.

Technology and equipment:

Foreign companies primarily control the special fine heavy calcium powder. They include the world’s calcium carbonate giants – Swiss OMYA, French IMERYS, and so on.

Foreign companies, like German ALPINE and ATRITOR, dominate the processing equipment technology industry. They also control process technology and are from countries like France and Japan. Foreign-funded enterprises starved the market after gaining a monopoly. This created a gap in the domestic market, leading to high membrane costs. This has hurt the market competitiveness of my country’s membrane products.

The good news is that we at EPIC Powder Machinery have made many years of hard work. After many years in the calcium carbonate industry, we have mastered the production of calcium carbonate for breathable membranes. This includes a full production line from grinding to modification.

Products:

The particles are too small. But, they disperse poorly and absorb lots of oil. This will make the film quality unstable and increase mixing work. Small powders have large specific surface and area. Yes, it is easy to cause powder agglomeration. This forms false large particles. It makes the powder hard to disperse and harms the stability and use of the breathable membrane production process.

If the particles are too large or not spherical, the pores in the film will grow after casting. This will make the breathable film let water through. In severe cases, the film may break. Moreover, if the particles are too large, their performance will be affected.

How to optimize the production process of calcium carbonate for breathable membranes?

The heavy calcium dry preparation process has a core process: grinding. It directly affects the powder’s quality. According to the process for heavy calcium vertical mills, the powder is crushed. Its particle size must be controlled. We must ensure the powder meets the needs for breathable membranes. Core processes and equipment are key. The feed size, roller pressure, and disc speed are crucial in grinding. So are material thickness and classifier speed. In classification, fan pressure and air volume matter a lot.

If you are interested in making calcium carbonate for breathable membranes, you can contact us.