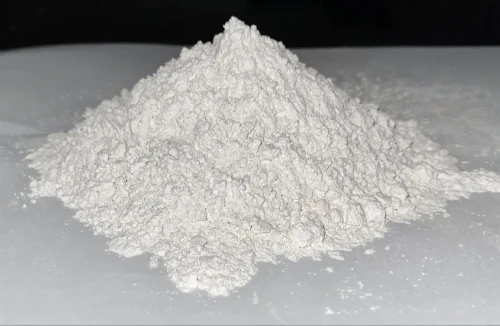

In the world of powders, heavy calcium holds a significant place due to its versatile applications in various industries. Heavy calcium refers to heavy calcium carbonate, a mineral compound with distinct characteristics and properties. This article aims to provide comprehensive information about heavy calcium, including its features, industrial applications, and the primary production equipment used for manufacturing heavy calcium powder.

What is Heavy Calcium?

Heavy calcium, also known as heavy calcium carbonate (CaCO3), is a powdered form of calcium carbonate that has a higher density compared to other forms. It is derived from natural limestone or marble deposits through a series of extraction and processing techniques. The resulting product consists of fine particles with a larger particle size range, typically between 5 to 20 microns.

Characteristics of Heavy Calcium:

- Density: Heavy calcium exhibits a higher bulk density ranging from 1.1 to 1.4 g/cm³, making it denser compared to other calcium carbonate forms. This property makes heavy calcium suitable for applications requiring increased weight or filling capabilities.

- Particle Size: Heavy calcium has a larger particle size distribution, which contributes to its higher density. The larger particles allow for better flowability and can enhance certain material properties in different applications.

- Whiteness: Heavy calcium offers excellent whiteness properties, providing superior brightness and opacity to the final products it is incorporated into. This characteristic makes it highly desirable in industries where brightness and visual appeal are crucial, such as paper, paints, and coatings.

- Chemical Stability: Heavy calcium carbonate showcases outstanding chemical stability, ensuring its durability under various environmental conditions without significant degradation. This stability helps preserve the quality and integrity of materials containing heavy calcium powder.

Industrial Applications of Calcium Powder:

Heavy calcium finds extensive use across multiple industries, including:

- Paper Industry: Heavy calcium acts as a filler in the paper-making process, improving opacity, smoothness, and printability. It enhances paper quality, making it ideal for high-quality printing and writing papers.

- Plastics Industry: Heavy calcium carbonate is utilized as a reinforcing agent and filler in plastics production. It improves mechanical properties, stiffness, and impact resistance of plastic products, contributing to their overall performance.

- Paints and Coatings: Heavy calcium functions as an extender pigment in paints and coatings, enhancing coverage, durability, and weather resistance. It provides better hiding power and contributes to the even distribution of pigments.

- Construction Materials: Heavy calcium is utilized in the production of various construction materials such as adhesives, sealants, concrete, and mortar. Its reinforcing and binding properties improve the strength and durability of these materials.

- Pharmaceuticals: Heavy calcium carbonate can be used as an excipient in tablet formulations or as a calcium supplement in dietary supplements. It provides a source of calcium and aids in maintaining bone health.

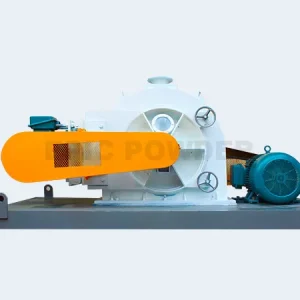

Primary Production Equipment for Heavy Calcium Powder:

The production of heavy calcium powder involves specific equipment designed to extract, process, and refine the raw materials. The main equipment used includes:

- Crushers: Crushers are employed to reduce the size of raw materials, such as limestone or marble, to a suitable feed size for further processing.

- Grinding Mills: Grinding mills, including ball mills, Raymond mills, and vertical roller mills, are used to finely grind the raw materials into the desired particle size range. These mills operate by applying mechanical forces to break down the particles.

- Classifiers: Classifiers are utilized to separate and classify the ground heavy calcium particles according to their size. They ensure precise control over the particle size distribution and help achieve the desired product specifications.

- Air Separators: Air separators are employed to remove fine particles from the heavy calcium powder, ensuring the final product meets the required standards of purity and quality.

Heavy calcium, or heavy calcium carbonate, is a valuable powder material with distinct characteristics and widespread industrial applications. Its higher density, larger particle size range, excellent whiteness, and chemical stability contribute to its versatility and desirability in various industries. From paper and plastics to paints and coatings, heavy calcium plays a crucial role in enhancing product performance and quality. The production of heavy calcium powder involves specific equipment such as crushers, grinding mills, classifiers, and air separators. Understanding the features, applications, and production processes of heavy calcium empowers industries to utilize this powder effectively and efficiently in their respective fields.