[In general, mesh number × aperture (micrometers) ≈ 15000.] For example, a 100-mesh screen has a 150-micron aperture. A 200-mesh screen has a 75-micron aperture. A 300-mesh screen has a 48-micron aperture. A 500-mesh screen has a 30-micron aperture. Below is a conversion between common mesh numbers and particle sizes.

| Mesh | Micron (μm) | Mesh | Micron (μm) | Mesh | Micron (μm) | Mesh | Micron (μm) |

| 2 | 8000 | 28 | 600 | 100 | 150 | 250 | 58 |

| 3 | 6700 | 30 | 550 | 115 | 125 | 270 | 53 |

| 4 | 4750 | 32 | 500 | 120 | 120 | 300 | 48 |

| 5 | 4000 | 35 | 425 | 125 | 115 | 325 | 45 |

| 6 | 3350 | 40 | 380 | 130 | 113 | 400 | 38 |

| 7 | 2800 | 42 | 355 | 140 | 109 | 500 | 25 |

| 8 | 2360 | 45 | 325 | 150 | 106 | 600 | 23 |

| 10 | 1700 | 48 | 300 | 160 | 96 | 800 | 18 |

| 12 | 1400 | 50 | 270 | 170 | 90 | 1000 | 13 |

| 14 | 1180 | 60 | 250 | 175 | 86 | 1250 | 10 |

| 16 | 1000 | 65 | 230 | 180 | 80 | 2000 | 6.5 |

| 18 | 880 | 70 | 212 | 200 | 75 | 5000 | 2.6 |

| 20 | 830 | 80 | 180 | 230 | 62 | 8000 | 1.6 |

| 24 | 700 | 90 | 160 | 240 | 61 | 10000 | 1.3 |

There are many corresponding relationships above. If you don’t have this table at hand, you can also remember the rough conversion method below.

To convert between mesh and microns, you can use the following relationships:

- Mesh to Microns: The size of a mesh screen is defined by the number of openings per linear inch. The formula to convert mesh size to microns is:Microns=25,400Mesh NumberMicrons=Mesh Number25,400For example, a 100 mesh screen would have an opening size of approximately:Microns=25,400100=254 micronsMicrons=10025,400=254 microns

- Microns to Mesh: To convert microns back to mesh, you can rearrange the formula:Mesh Number=25,400MicronsMesh Number=Microns25,400For example, if you have a particle size of 200 microns, the corresponding mesh size would be:Mesh Number=25,400200=127Mesh Number=20025,400=127

Example Conversions

- 80 Mesh:

- Micron Size: 25,40080≈317.58025,400≈317.5 microns

- 200 Microns:

- Mesh Size: 25,400200=12720025,400=127 mesh

These conversions are useful in various industries, including filtration and material processing, where precise particle sizes are critical.

What does particle size distribution mean? What do D10, D50, and D90 stand for?

The particle size is defined as the size of the space occupied by the particle. The range is very wide, ranging from a few tenths of a nanometer to several thousand microns. The size of the particle is called “grain size“, also known as “particle size” or “diameter”. The equivalent particle size is the diameter of a sphere. It’s the closest match to the particle’s physical behavior. If a combination of spheres is a better match, use that instead. Of course, for non-spherical particles, their size depends on the measurement method. We can only define their size as “equivalent.”

Particle size distribution

A measurement system is monodisperse if all its particles are the same size. If not, it has a mix of particles of different sizes. At this time, it is necessary to pay attention to the particle size distribution diagram.

The most commonly used parameters for interpreting the particle size distribution diagram include:

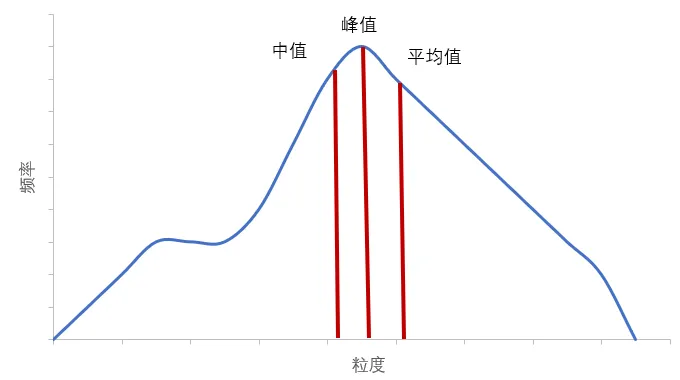

Mean: the average particle size of the system

Median: the particle size in the middle of the particle size distribution

Peak: the particle size with the highest frequency

Note that if the particle size distribution diagram is not symmetrical, these three parameters are not equal.

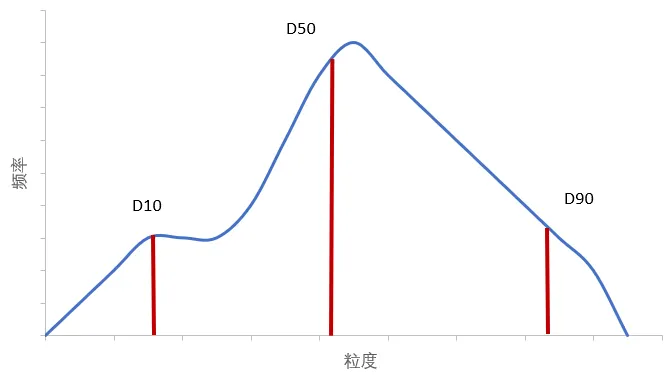

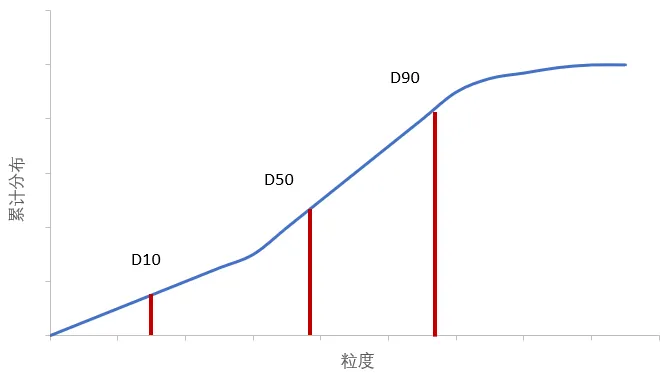

D10: The particle size at which 10% of the system’s particles are smaller.

D50: The particle size at which 50% of the system’s particles are.

D90: The particle size at which 90% of the particles are.

For example: If D10=3 μm, D50=10 μm, and D90=12 μm of a sample, then, by particle size distribution: 10% of the particles are ≤3 μm; 50% are ≤10 μm; and 90% are ≤12 μm.

Powder processing cannot be separated from particle size detection

Many industries rely on the link between powder processing and particle size detection. Accurate particle size measurement affects product quality, processing efficiency, and material performance. Here is a summary of recent advancements and methodologies in this field:

Importance of Particle Size Detection

Quality Control: Particle size is key. It affects powders’ flow, reactivity, and density. Accurate detection helps ensure product consistency and quality in manufacturing processes.

Process Optimization: Monitoring particle size can improve production. It reduces waste and increases yield. This is particularly important in industries like pharmaceuticals, food, and materials engineering.