Due to the surface effect and hydrophilic and oleophobic properties of nano-calcium carbonate, unmodified nano-calcium carbonate has shortcomings such as dispersion, poor affinity, and easy agglomeration when applied to organic polymers, seriously affecting the quality of the product. , leading to interface defects between the two materials, and the higher the filling amount of nano-calcium carbonate, the more obvious these shortcomings become, and excessive filling may even destroy the original performance of the material.

Therefore, nano calcium carbonate is generally not used directly. Nano-calcium carbonate particles after surface modification usually form “soft agglomerations”, and this “soft agglomeration” can be disintegrated through mechanical shearing and ultrasonic oscillation, with just a little handling during the application process. Therefore, surface modification of nanometer calcium carbonate is of great significance.

Nano calcium carbonate modifier types

The modification route of nano calcium carbonate usually adopts grafting and coupling reactions. According to the differences in structure and characteristics, modifiers can be divided into surfactants, coupling agents, polymers and inorganic substances.

Surfactant

Currently, the most commonly used surfactants include fatty acids, phosphates and polymer compounds.

The long-chain alkyl group structure at one end of the fatty acid modifier molecule is similar to that of polymers. According to the principle of similar description, they can be better compatible with the polymer matrix; polar groups such as carboxyl groups at the other end of the molecule can be used in inorganic Physical or chemical adsorption occurs on the surface of materials (such as nano-calcium carbonate).

Phosphate ester mainly reacts with phosphate ions and calcium ions to form phosphate, which is coated on the surface of calcium carbonate.

Modification is carried out to improve the lipophilic and hydrophobic properties of nanometer calcium carbonate surface.

Polymer compounds are modified by controlling the particle size of nanoparticles to change their surface state. Polymer compounds containing sulfonic acid groups or carboxylic acid groups can be used as modifiers, mostly ionizable groups.

Coupling agent

The coupling agent is modified by combining two materials with very different properties, calcium carbonate and organisms, through chemical reactions or physical entanglements with the functional groups on the surface of calcium carbonate respectively. Through the molecular bridge on the surface of nanometer calcium carbonate, the coupling agent is modified. , improving the compatibility between nanometer calcium carbonate and organic materials.

Titanate coupling agent and aluminate coupling agent are currently the most commonly used coupling agent nano-calcium carbonate modifiers.

Polymers and inorganics

Polymer is a type of modifier that forms a physical or chemical adsorption layer on the surface of calcium carbonate through directional adsorption and gives it charge characteristics to prevent calcium carbonate particles from agglomerating and agglomerating to improve dispersion.

As a modifier, inorganic electrolytes are adsorbed on the surface of nano-calcium carbonate, which can significantly increase the absolute value of the surface potential of nano-calcium carbonate. At the same time, the degree of wetting between the surface of nano-calcium carbonate and water is also enhanced, which to a certain extent prevents nano-calcium carbonate from forming. aggregation in water.

Commonly used inorganic electrolyte modifiers include sodium aluminate, sodium silicate, alum, condensed phosphoric acid, etc.

Nano calcium carbonate modification method

The current methods used for surface modification of nanometer calcium carbonate mainly include: local chemical reaction modification, surface coating modification, microemulsion modification, mechanical modification and high-energy surface modification.

Local chemical reaction modification

The local chemical reaction modification method mainly achieves the modification purpose through the chemical reaction between the surface functional groups of nanometer calcium carbonate and the modifier. It is divided into two processes: dry method and wet method.

Dry modification: Dry modification is to add nano-calcium carbonate into a high-speed kneader, rotate and heat it. When it is heated to a certain temperature, add a surface modifier and perform kneading modification. Dry modification adopts physical blending method, and the process is relatively simple. However, because the particle size of nano-calcium carbonate is very small, between 40-60nm, it has a large specific surface area and static electricity, and it is easy to condense into larger particles. Agglomeration reduces the activation degree of nano-calcium carbonate particles and poor dispersion, so the modification effect is not ideal.

Wet modification: Wet modification is to add surface modifiers to nano-calcium carbonate suspension for surface treatment in the later stage of carbonization, and complete surface modification under certain temperature and stirring conditions. Wet modification is used by calcium carbonate manufacturers, and its process flow is:

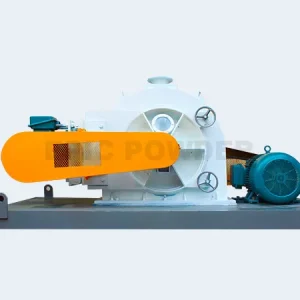

After wet modification of nano calcium carbonate, it needs to be dried, dispersed, and packaged. For the dispersing part, three types of equipment are recommended as dispersers. It has better effect.

- Prepare a certain mass of Ca(OH)2 suspension, add an appropriate amount of crystal form control agent under heating and stirring conditions, and then introduce a mixed gas of CO2 and N2 to carbonize, and measure the carbonization rate by titration method;

- Add an appropriate amount of surface modifier to the nano-calcium carbonate suspension and stir thoroughly to make the surface modifier evenly coat the surface of nano-calcium carbonate;

- Obtain wet-modified nano-calcium carbonate particles through suction filtration, drying, crushing and sieving.

Surface coating modification method

It refers to a modification method in which the surface modifier and the nanometer calcium carbonate surface are connected only by van der Waals force or physical methods without chemical reaction.

This method can add surfactant to the solution while preparing nano-calcium carbonate, achieving the purpose of simultaneous preparation and modification, because the presence of surfactant makes the calcium carbonate produced by this method have good dispersion properties. improve.

Microemulsion modification method

The microemulsion modification method is also called encapsulation modification. This method is modified by coating the surface of nano-calcium carbonate with a film of other substances to change the inherent characteristics of the particle surface.

Although this method is similar to the surface coating modification method, the film coated on the surface of nano-calcium carbonate after modification by this method is more uniform than that modified by surface coating.

Mechanochemical modification methods

Mechanochemical modification method is a modification method that uses strong mechanical force to purposely activate the particle surface, causing the molecular lattice to shift, changing its physical and chemical structure and surface crystal structure, and improving the reactivity of particles with organic or inorganic substances. .

This modification method is very effective for large particles of calcium carbonate. As for nanoscale calcium carbonate, due to its small particle size, the mechanochemical modification method through mechanical crushing and grinding can no longer exert excellent modification. Sexual effects.

Giving full play to the nano-effects of nanoparticles, improving the surface properties of nanoparticles, improving the dispersion and compatibility of nanoparticles in the matrix, and preparing composite materials with excellent performance will broaden the application fields of materials.

Nano calcium carbonate is a high-end product in the field of calcium carbonate. As the quality of my country’s nano calcium carbonate improves, the cost continues to decrease. Now it can not only replace imports, but also begin to be exported to the international market. I believe that the market prospects of domestic nano calcium carbonate will become more and more promising. .