Advanced ceramics excel in many properties. They have mechanical, acoustic, optical, thermal, electrical, and biological qualities. They are used in high-end tech fields like aerospace, electronics, and biomedicine. They are also used in advanced manufacturing. There are many types of advanced ceramics. Each type has its own traits. For example, alumina ceramics resist oxidation. Silicon nitride ceramics are strong and resist electrical corrosion. Zirconium oxide ceramics are tough and biocompatible.

High purity alumina

High-purity alumina (4N and above) has many advantages. It is very pure, hard, and strong. It resists high temperatures and wear. It also has good insulation and stable chemical properties. Its high-temperature shrinkage is moderate. It has good sintering performance. Its properties are better than those of regular alumina powder. They are optical, electrical, magnetic, thermal, and mechanical. It is a top, high-value material. It has a wide use in the modern chemical industry. High-purity alumina is a top high-performance alumina product. It is widely used in high-tech industries. These include fluorescent materials, transparent ceramics, electronic devices, new energy, catalytic materials, and aerospace.

High-purity alumina transparent ceramics have good light transmittance. They also outperform opaque ceramics in mechanical, optical, thermal, and electrical properties. Alumina ceramic substrates are the most used in today’s electronics. They are the basic materials for integrated circuit chips. High-purity alumina, used in ceramic substrates, has high-end uses. These include precision components for semiconductor equipment. Such ceramics have more stringent performance requirements than general fine ceramics.

The polishing liquid’s abrasive part is crucial. High-purity alumina is ideal for it. With the rise of the silicon carbide semiconductor industry, we must now use high-purity ultrafine alumina for semiconductor polishing.

Bomu stone

Boehmite contains one crystal water. Its formula is γ-Al2O3·H2O or γ-AlOOH. It is a type of alumina hydrate.

Its high surface area and large porosity make it a key raw material for fast, efficient, and reusable adsorbents. It retains its shape after a phase change. Its biocompatibility makes it useful in orthopedics and dentistry. It shines in biomedicine. Its unique flame retardancy, good filling, and leakage resistance make it widely used in high-performance, ultra-thin copper-clad laminates. Its stable rhombic structure and high-density hydroxyl groups on the surface allow for modification by various functional groups. It is a raw material for making expensive supported catalysts and reagents.

Aluminum Nitride

As electronic chips get faster and smaller, their heat output has soared. So, the right packaging and better heat dissipation are now bottlenecks in developing power devices. Ceramic materials have high thermal conductivity and heat resistance. They also have high strength and insulation. They match the thermal properties of chip materials. So, they are ideal for power device packaging substrates.

Among them, aluminum nitride is the ceramic material with the best thermal conductivity. Its theoretical thermal conductivity can reach 320W/(m·K). Commercial products have a thermal conductivity of 180W to 260W/(m·K). This makes it suitable for high-power, high-lead, large-size chip packaging substrates. In addition to high thermal conductivity, its excellent properties also include:

(1) The thermal expansion coefficient (4.3×10-6/℃) matches that of semiconductor silicon materials ((3.5~4.0)×10-6/℃);

(2) Good mechanical properties, higher than BeO ceramics and close to alumina;

(3) Excellent electrical properties, with extremely high insulation resistance and low dielectric loss;

(4) Multi-layer wiring can be performed to achieve high density and miniaturization of packaging;

(5) Non-toxic and environmentally friendly.

Silicon Nitride

Silicon nitride is currently mainly used as a ceramic material. Silicon nitride ceramics are vital in industry, especially in high-tech fields. For example:

Of them, bearing balls are the most used silicon nitride ceramic products. Their annual output is 30% of the world’s high-performance silicon nitride products. Silicon nitride ceramic bearing balls are better than steel balls. They are lighter, can withstand high temperatures, are self-lubricating, and resist corrosion. Their fatigue failure mode is the same as that of steel balls. Thus, silicon nitride ceramic bearing balls have many uses. They are in precision bearings for machine tools, autos, and wind turbines. They are also in high-temperature, corrosion-resistant petrochemical bearings.

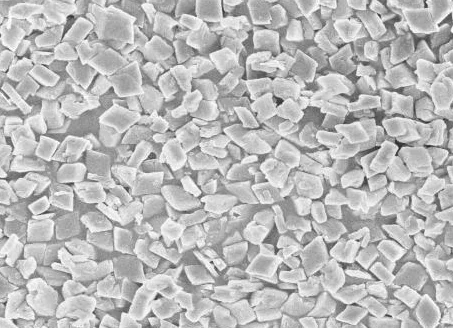

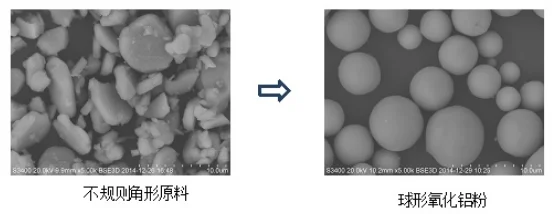

Spherical Alumina

Of the many thermal conductive powders, spherical alumina is the most popular in high-end uses. Its high thermal conductivity, high fill factor, good flow, and low cost make it ideal. It has a mature production process and many specs.

Also, spherical powders can greatly improve products. Their regular shape, high density, and good flow are key. Spherical Al2O3 powders have thermal conductivity. They are also used in ceramics and catalyst carriers. They are widely studied in those fields.

Barium Titanate

Barium titanate (BaTiO3) is an ABO3 type perovskite structure. Since the 20th century, barium titanate ceramics have excellent dielectric properties. So, they are used as a dielectric material for capacitors. It is a widely used electronic ceramic powder. It is also the matrix material for making electronic components. Therefore, it is called the “pillar of the electronic ceramic industry.”

Nanocomposite zirconium oxide

Nanocomposite zirconia is a type of zirconia. A stabilizer can make it keep a tetragonal or cubic phase at room temperature. The stabilizers are mainly rare earth oxides and alkaline earth metal oxides. The former include Y2O3 and CeO2. The latter are CaO and MgO.

As science and technology advance, new special-use instruments and equipment are emerging. They must meet high demands for materials and component functions. There is a rapidly growing demand for nano-composite zirconia materials. Their products are tough, heat-resistant, wear-resistant, corrosion-resistant, and optically special. Yttria-stabilized zirconia is the most widely used and most representative nano-composite zirconia.

It has high oxygen ion conductivity and good mechanical properties. It resists oxidation and corrosion. It has a high thermal expansion coefficient and low thermal conductivity. It is stable and resistant to oxidation.

It is widely used in structural and functional materials. They are: oxygen sensors, pumps, solid fuel cells, ferroelectric ceramics, and aircraft engine coatings.

High purity silicon carbide

Silicon carbide materials fall into two categories: ceramics and single crystals. As a ceramic material, its purity is not very important in general applications. But, it must be high in special cases. For example, it is used as a precision component in semiconductor equipment, like lithography machines. This is to avoid affecting the purity of silicon wafers.

However, SiC’s properties make it hard to grow single crystals. This is mainly because, at normal pressure, there is no liquid phase with a Si:C ratio of 1:1. The mainstream semiconductor industry’s mature methods can’t grow it. These methods include the direct pulling and falling crucible methods. To solve this, scientists have worked hard to find ways to make high-quality, large, cheap SiC crystals. The more popular methods are PVT, the liquid phase method, and high-temperature vapor phase chemical deposition.