In the food processing industry, achieving consistent 입자 크기, preserving product integrity, and maintaining hygiene standards are critical priorities. Among the various grinding technologies available, pin mills have emerged as a preferred choice for food applications due to their versatility, efficiency, and precision. This article explores the unique advantages of pin mills and why they are particularly suited for grinding food products.

Gentle yet Efficient Grinding Mechanism

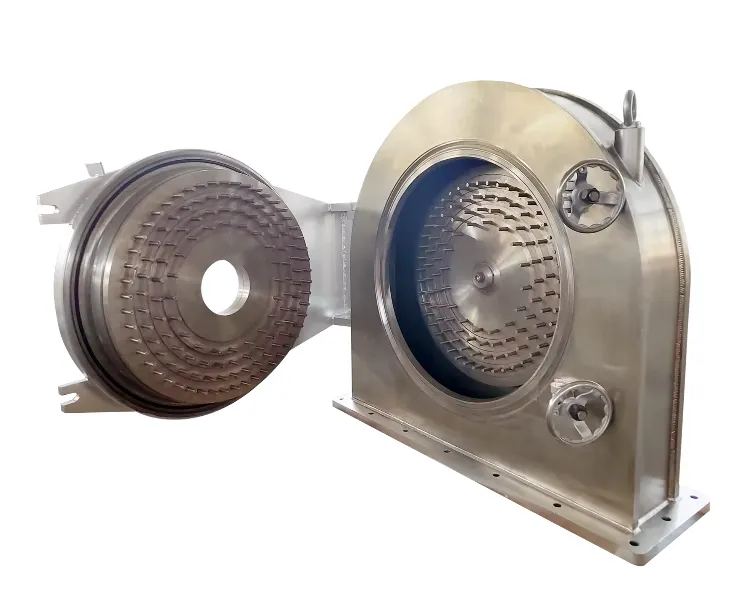

Pin mills operate using a combination of impact and shear forces generated by rotating discs fitted with pins. As food materials pass through the grinding chamber, the pins collide with particles, breaking them down into smaller sizes. Unlike traditional grinding methods that rely on high heat or friction, pin mills minimize thermal degradation. This gentle process is ideal for heat-sensitive ingredients such as spices, herbs, and vitamins, ensuring flavors, colors, and nutritional values remain intact.

Precise Control Over Particle Size

Food applications often require strict control over particle size distribution. Pin mills allow operators to adjust parameters like rotor speed, feed rate, and pin configuration to achieve the desired fineness. Whether producing coarse grains for textured snacks or ultra-fine powders for instant beverages, pin mills deliver consistent results. Their ability to handle both brittle and fibrous materials—such as sugar, starch, or dried vegetables—makes them adaptable to diverse product requirements.

Hygienic and Easy-to-Clean Design

Food safety regulations demand equipment that minimizes contamination risks. Modern pin mills are constructed with stainless steel surfaces, smooth interiors, and minimal crevices, reducing the likelihood of bacterial buildup. Many models are designed for quick disassembly, enabling thorough cleaning and sterilization between batches. This compliance with hygiene standards is crucial for dairy, infant formula, or allergen-free product lines.

Energy Efficiency and Scalability

Pin mills consume less energy compared to hammer mills or jet mills, thanks to their streamlined grinding mechanism. The absence of screens or grates reduces energy waste while maintaining high throughput. Additionally, pin mills are scalable—smaller units suit laboratory testing or niche products, while industrial-scale models handle large-volume production. This flexibility aligns with the needs of startups and established manufacturers alike.

Versatility Across Food Categories

From dry powders to semi-moist ingredients, pin mills accommodate a wide range of food materials:

- Spices and Seasonings: Retain volatile oils and aromas.

- Dairy Products: Grind lactose or milk powders without clumping.

- Grains and Legumes: Process flours or protein isolates.

- Confectionery: Create smooth chocolate or sugar pastes.

Their ability to grind without adding moisture or altering 화학적인 composition ensures product consistency across batches.

Reduced Waste and Cost-Effectiveness

Pin mills generate minimal fines or oversized particles, optimizing yield and reducing material waste. Their low maintenance requirements—due to fewer wearable parts—translate to lower operational costs over time. For businesses prioritizing sustainability, the efficient use of raw materials supports eco-friendly production practices.

결론

Pin mills stand out in the food industry for their ability to balance precision, hygiene, and efficiency. By preserving product quality, meeting regulatory standards, and adapting to diverse processing needs, they offer a reliable solution for modern food manufacturers. As demand for clean-label, nutrient-rich, and customized food products grows, pin mills will continue to play a pivotal role in shaping the future of food grinding technology.

에픽파우더

에픽 파우더는 초미립자 분말 산업 분야에서 20년 이상의 경력을 보유하고 있습니다. 초미립자 분말의 파쇄, 분쇄, 분급 및 개질 공정에 중점을 두고 초미립자 분말의 미래 개발을 적극적으로 추진하고 있습니다. 무료 상담 및 맞춤형 솔루션을 원하시면 지금 바로 문의하세요! 저희 전문가 팀은 고품질 제품과 서비스를 제공하여 고객의 분말 가공 가치를 극대화하기 위해 최선을 다하고 있습니다. 에픽 파우더 - 믿을 수 있는 분말 가공 전문가!