In the world of particle size reduction, keeping the product pure is key. This is especially true in industries where the final product’s quality matters a lot. The jet pulverizer, a cutting-edge air-based grinding tech, is crucial for keeping the grinding process pure. It uses compressed air to efficiently cut down particle sizes while keeping the material intact. This makes it perfect for applications that need top-notch purity.

The jet pulverizer’s secret to keeping the product pure lies in how it works. Unlike old-school grinding methods that can bring in contaminants, the jet pulverizer uses air to keep things clean. It uses high-velocity air to break down particles. This makes the final product free of unwanted stuff. This keeps the product’s quality high, making it great for even the toughest applications.

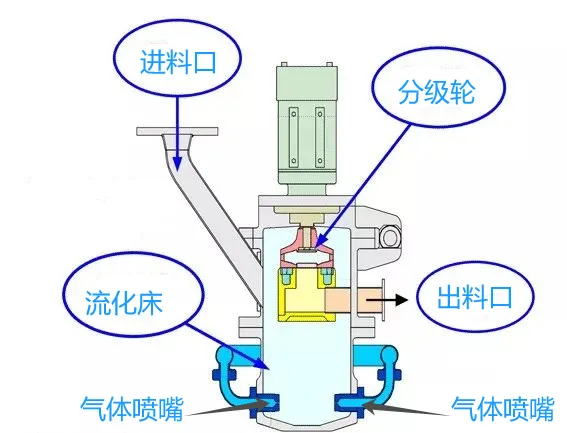

A detailed illustration of a jet pulverizer in action, showcasing the process of particle size reduction with fine powders being produced, swirling air currents and micro-particles visible, high-tech machinery with precision engineering, a clean and sterile environment emphasizing purity, dynamic motion capturing the grinding process.

Key Takeaways

- The jet pulverizer uses air-based grinding tech to keep particle size reduction pure.

- Its clean operating principles stop foreign matter from getting into the final product.

- The jet pulverizer’s air-based method ensures top-notch product quality and purity. It’s a go-to for industries with high standards.

- The jet pulverizer can grind materials well using compressed air. It keeps them intact.

- The jet pulverizer’s special features ensure the delivery of pure and high-quality end-products.

Understanding the Basics of Jet Pulverization Technology

Jet pulverization, or fluid energy milling, is a versatile, efficient tech. It’s used for the micronization of various materials. At its core, the process relies on particle-on-particle collisions. High-velocity air jets collide particles, reducing their size.

Key Components of a Jet Pulverizer System

A typical jet pulverizer system has several key components. These include:

- Feeding mechanism: Introduces the material into the system

- High-speed air nozzles: Generate the high-velocity air jets that drive the particle collisions

- Grinding chamber: Allows for the particle-on-particle interactions

- Product collection system: Captures the micronized particles for further processing

Fundamental Operating Principles

The jet pulverization process uses high-pressure air’s kinetic energy. It propels the feed material particles at high velocities. As these particles collide in the grinding chamber, the particle-on-particle collisions lead to size reduction and micronization.

Types of Jet Pulverization Methods

There are several variations of jet pulverization techniques. Each has its own unique characteristics and applications. These include:

- Opposed Jet Milling: Air streams collide, creating a high-intensity zone.

- Spiral Jet Milling: Particles are introduced tangentially. This creates a spiral motion in the grinding chamber.

- Fluidized Bed Jet Milling: An upward air stream suspends the particles. It enables gentle and efficient grinding.

These different jet pulverization methods offer versatility. They handle many materials. They range from soft to hard, and from temperature-sensitive to abrasive. They maintain high product purity throughout the micronization process.

The Role of Compressed Air in Maintaining Product Purity

In the world of jet pulverization, compressed air is key to keeping products pure and of high quality. It acts as the main grinding medium. The air’s quality is crucial to keep the process clean.

A jet pulverizer runs on compressed air. It pushes raw material through the grinding chamber fast. To keep the clean air supply safe, advanced air filtration systems are used. These systems remove contaminants and ensure the air is very pure.

| Air Quality Parameter | Recommended Specification |

| Particle Size | 0.01 microns or less |

| Oil Content | 0.01 ppm or less |

| Moisture Content | -40°C (-40°F) dew point or less |

By monitoring air quality, jet pulverizer operators can keep the grinding process clean. This protects the final product’s purity and quality.

The mix of strong compressed air supply and top-notch air filtration is vital in jet pulverization. It helps manufacturers make high-quality, pure materials that meet strict industry standards.

Design Features That Prevent Cross-Contamination

Keeping pharmaceutical and critical products pure is key. The jet pulverizer’s design is crucial here. It uses sanitary design, pharmaceutical-grade materials, and crevice-free construction to avoid contamination during grinding.

Material Selection and Surface Finishes

The materials in jet pulverizers are carefully chosen. Stainless steel is often used because it’s easy to clean and sterilize. Specialized surface treatments, like electropolishing, also help prevent particles and microbes from sticking.

Sealing Systems and Isolation Techniques

Sealing and isolation are vital to stop contamination. Jet pulverizers have sealing mechanisms and isolation techniques to keep products safe. These systems, like airlock chambers, help keep the process clean and pure.

Clean-in-Place Capabilities

Modern jet pulverizers have clean-in-place (CIP) systems. These allow for automated, thorough cleaning without taking the equipment apart. This saves time, reduces errors, and keeps the equipment clean and validated.

| Design Feature | Benefit |

| Sanitary Design | Minimizes particle buildup and microbial growth |

| Pharmaceutical-grade Materials | Withstand rigorous cleaning and sterilization |

| Crevice-free Construction | Prevents contamination in hard-to-reach areas |

| Sealing Systems and Isolation Techniques | Create physical barriers to maintain product purity |

| Clean-in-Place Capabilities | Ensure consistent, validated cleanliness |

“Implementing a comprehensive approach to sanitary design is essential for maintaining the purity and integrity of critical products throughout the jet pulverization process.”

Jet Pulverizer Operation Parameters for Maximum Purity

To get the highest purity in grinding, you need to adjust several key settings. These include air pressure, feed rate, and classifier speed. By tweaking these, you can control particle size well and avoid contamination.

It’s vital to optimize the process for high purity. The air pressure in the jet pulverizer must be just right. This ensures particles are broken down efficiently without damage. Also, adjusting the feed rate helps avoid clumping and keeps particle sizes consistent.

The classifier system is also crucial for purity. By adjusting the classifier speed, you can pick the right particle sizes. This means fewer unwanted particles in your final product.

| Parameter | Optimization Goal | Impact on Purity |

| Air Pressure | Maintain optimal pressure for efficient particle size reduction | Improves particle size control and minimizes cross-contamination |

| Feed Rate | Adjust feed rate to prevent agglomeration and maintain consistent particle size | Enhances particle size control and ensures a more uniform product |

| Classifier Speed | Optimize classifier speed to selectively separate particles of the target size range | Enhances particle size control and improves overall product purity |

Particle Size Control and Classification Methods

In the world of jet pulverization, controlling particle size is key. This ensures product purity and consistency. Manufacturers use advanced methods like internal classification systems, real-time monitoring, and strict quality control.

Internal Classification Systems

Jet pulverizers have built-in systems to sort particles by size and density. These systems use centrifugal forces and air flow. They make sure only the right-sized particles are kept for further processing.

Larger or smaller particles are sent back for recirculation or removal. This way, manufacturers can always produce powders with the right size.

Size Distribution Monitoring

Keeping an eye on particle size in real-time is vital. Technologies like laser diffraction or image analysis give instant data. This lets operators adjust the process as needed.

This approach ensures the product meets quality standards for in-line particle sizing, real-time monitoring, and product consistency.

Quality Control Measures

Quality control is the backbone of jet pulverized product purity and consistency. It includes regular sampling, sieve analysis, and microscopic checks. These steps verify that the product meets the required standards.

By following these quality control steps, manufacturers can confidently provide high-purity powders. These meet the exacting standards of their customers.

| Technique | Benefit |

| Internal Classification Systems | Maintains precise particle size distribution |

| In-line Particle Sizing | Provides real-time monitoring of particle characteristics |

| Comprehensive Quality Control | Verifies product purity and consistency |

Maintaining Sterile Conditions During Processing

In the world of aseptic processing, keeping things sterile is key. This is especially true for industries like pharmaceuticals and food processing. Jet pulverizers need a cleanroom and sterile air to avoid contamination and keep products pure.

Cleanroom integration is vital for sterile conditions in jet pulverization. These special areas are made to have fewer airborne particles and microorganisms. They use advanced filters and strict cleaning and personnel rules to stay clean.

Sterile air systems are crucial for cleanrooms. They use HEPA filters to clean the air. It controls temperature, humidity, and air pressure. This keeps the air clean and safe for processing.

Aseptic processing techniques add to the safety of jet pulverization in cleanrooms. These methods use special equipment and strict controls to prevent contamination. We watch every step, from handling materials to packaging. This keeps products safe and pure.

| Sterile Condition Requirement | Importance | Key Measures |

| Cleanroom Environment | Minimizes airborne contaminants and maintains a controlled, hygienic setting | Advanced filtration systems, rigorous cleaning, strict personnel protocols |

| Sterile Air Supply | Ensures a constant supply of clean, filtered air to the cleanroom | HEPA filtration, temperature and humidity regulation, air pressure control |

| Aseptic Processing Techniques | Minimizes the introduction of foreign matter or microorganisms throughout the production process | Specialized equipment, sterilization procedures, strict process controls |

Impact of Feed Material Properties on Purity

Keeping the grinding process pure is key for manufacturers. The feed material’s hardness and moisture are crucial. These factors greatly affect the grinding process and the product’s quality.

Material Hardness Considerations

The hardness of the feed material is very important. Easier-to-grind materials, like friable ones, result in better purity and size consistency. Harder materials, however, need more energy and can lead to more impurities.

Moisture Content Management

Moisture in the feed material also matters a lot. Hygroscopic materials absorb moisture easily, causing problems during feed preparation. Too much moisture can lead to clumps, clogs, and contamination. It’s vital to manage moisture well to keep the product pure.

| Feed Material Property | Impact on Grinding Process | Recommended Mitigation Strategies |

| Material Hardness | Harder materials may require more energy-intensive grinding, leading to increased friability and contaminants | Utilize materials with lower hardness to improve grinding efficiency and minimize impurities |

| Moisture Content | Hygroscopic materials can absorb moisture, causing agglomeration, clogging, and cross-contamination | Implement moisture management techniques, such as drying or dehumidification, to maintain consistent material properties |

Optimization Techniques for Enhanced Purity

To get the best purity in jet pulverization, we need a few key steps. Tools like process simulation, CFD, and DOE are vital. They help fine-tune how the system works and its design for top performance.

Engineers can use process simulation software to test the jet pulverizer’s complex inner workings. They can see how air flows, particles move, and how different parts interact. This virtual testing saves time and money by avoiding the need for real prototypes.

CFD modeling goes deeper into the fluid dynamics inside the pulverizer. It helps engineers understand flow patterns, turbulence, and how particles behave. It helps spot and fix contamination risks. This makes the system safer and cleaner.

Design of experiments (DOE) is a methodical way to find out how different variables affect purity. It looks at things like air pressure, feed rate, and particle size. This approach helps identify the key factors for purity. It allows for precise adjustments to the system.

These advanced methods help manufacturers and users optimize their jet pulverizers. This ensures they always get high-quality results from their grinding processes.

Common Challenges and Solutions in Jet Pulverization

Jet pulverization is a top-notch method for achieving high purity in grinding. Yet, it comes with its own set of challenges. Operators often deal with wear, product recovery, and system upkeep. Luckily, there are effective ways to tackle these issues.

Troubleshooting Contamination Issues

Contamination is a big worry in jet pulverization. It can happen due to material buildup, wear, or bad sealing. To avoid this, regular checks, preventive care, and using durable materials are key. Also, having strong cleaning steps and CIP systems helps keep the system clean.

Performance Optimization Strategies

Keeping a jet pulverizer system running well is vital for quality and cost savings. You can do this by tweaking air pressure, checking particle sizes, and using advanced sorting methods. You can boost wear reduction, product recovery, and system maintenance. Just watch the system stats and adjust as needed.

| Challenge | Solution |

| Contamination Issues | Regular system inspections Preventive maintenance Use of wear-resistant materials Robust cleaning protocols Clean-in-place (CIP) capabilities |

| Performance Optimization | Optimize air pressure and flow rates Monitor particle size distribution Implement advanced classification techniques |

Industry Applications and Purity Requirements

Jet pulverizers are used in many industries, each needing different purity levels. In the pharmaceutical world, pharmaceutical micronization is key. Jet pulverizers help make sure products are very pure. They control particle size and prevent contamination, making high-quality medicines possible.

In the food industry, jet pulverizers are used to make food-grade powders that are very pure. They turn spices, seasonings, and plant proteins into fine, consistent powders. This meets strict food safety standards. It also keeps the nutritional and taste qualities of these ingredients intact.

Jet pulverizers are also used in making advanced materials. They help create ultra-fine, pure powders for new technologies. This includes ceramics, composites, and battery materials. Jet pulverizers help advance materials science. They control particle size and keep the process clean. They make it possible to create new products.

FAQ

A jet pulverizer system has several key parts. These include the feed hopper, nozzle(s), grinding chamber, classifier, and collection system. Together, they help grind materials using air and ensure the product is pure.

The jet pulverizer keeps purity high by using clean, filtered air for grinding. This air-based method avoids contamination from mechanical parts or grinding media. It ensures a clean milling environment.

There are several jet pulverization methods. These include fluid energy mills, micronizers, and particle-on-particle collision techniques. Each method uses air to grind materials finely and keep them pure.

Jet pulverizers are designed to avoid cross-contamination. They use sanitary materials, have no crevices, and have advanced seals. They also allow for easy cleaning and sterilization between batches.

To get the best purity, adjust air pressure, feed rate, and classifier speed. Using simulation and experimental design can fine-tune the system. This ensures consistent and high-quality products.

Jet pulverizers use internal classification systems and real-time monitoring. They also have quality control measures. These ensure the right particle size and product uniformity, keeping purity high.

Jet pulverizers can work in cleanrooms and use sterile air. This is crucial for pharmaceutical and food-grade products. It ensures aseptic processing conditions.

The hardness and moisture of the feed material affect grinding. Handling materials with different properties is key. It ensures the best grinding results and prevents contamination.