Pin milling (pin mill) is a versatile and efficient grinding method. It works by impact grinding. This happens using pins or hammers in a rotating chamber.

Pin mill is a type of impact mill that utilizes multiple rows of intermeshing pins or studs to achieve particle size reduction by impacting the particles against the pins.

Working Principle of Pin Mill

- Impact Grinding: Material is fed into the grinding chamber where it encounters the rotating pins.

- Particle Breakdown: The high-speed impact between the pins and the material results in the fragmentation and reduction of particles.

- Attrition Forces: Along with impact forces, attrition—caused by particles colliding against each other and the pins—further breaks down the material.

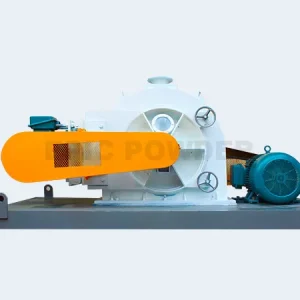

Components of a Pin Mill

- Rotating Pins: Sharp-edged pins or hammers rotate at high speeds to grind and reduce the size of the material.

- Grinding Chamber: Enclosed area where the material undergoes the grinding process under the action of the pins.

- Classifier (Optional): Some pin mills incorporate classifiers to control the particle size distribution of the output.

Advantages of Pin Milling

- High Efficiency: Rapid size reduction due to intense impact and attrition forces.

- Precise Particle Size Control: Capable of producing uniform ultra-fine particles with controlled distributions.

- Versatility: Suitable for processing a wide range of materials, including heat-sensitive and fragile substances.

Applications of Pin Milling

- Food Industry: Used for grinding spices, sugar, grains, and food additives.

- Pharmaceuticals: Ideal for micronizing active pharmaceutical ingredients (APIs) and excipients.

- Chemical Industry: Employed in processing pigments, dyes, and specialty chemicals.

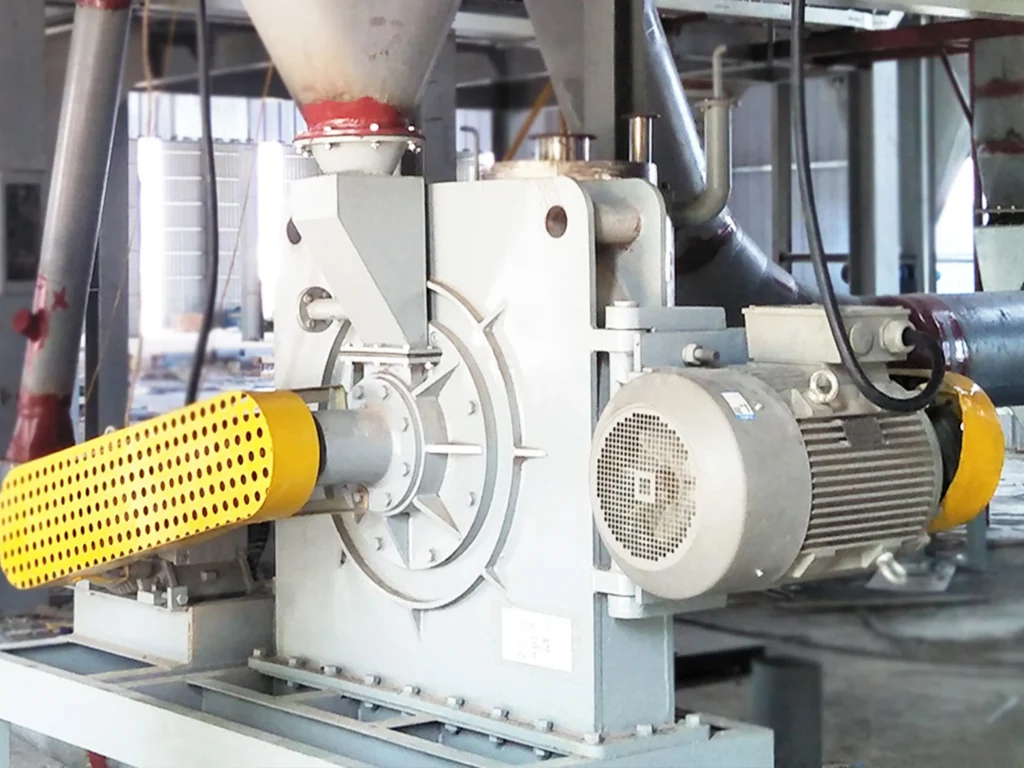

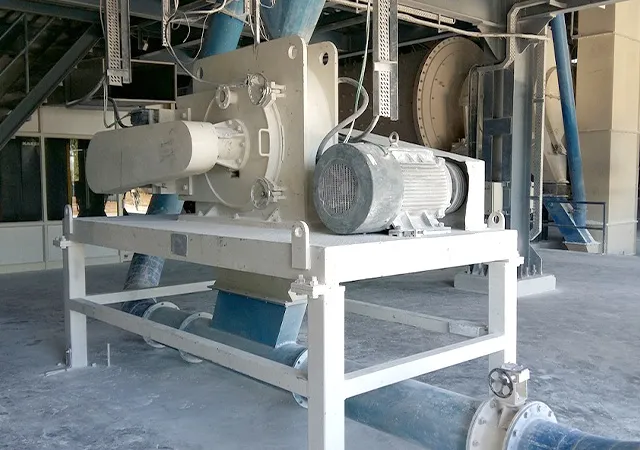

Pin Mill Customer Site Gallery

In conclusion, pin milling proves to be a versatile and effective technique for achieving precise particle size reduction through impact grinding mechanisms, making it a valuable tool across various industries for producing fine powders and achieving desired product specifications.