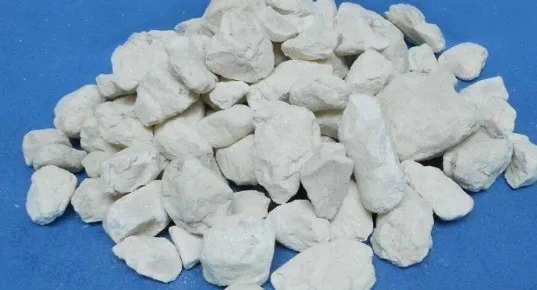

Limestone is a sedimentary rock composed mainly of calcite (calcium carbonate CaCO3).

It usually forms in marine or lake environments. Biological and chemical processes cause it to precipitate.

The characteristics and types of limestone are as follows:

Color: generally gray, white, yellow, brown, etc., depending on the impurities contained.

Texture: The texture is uniform and fine, but there are also cases of fossils or other rock fragments.

Structure: It can be granular, mud-crystalline, bioclasts, etc.

Hardness: Mohs hardness is about 3, relatively soft.

Solubility: It is easily soluble in acid and will produce carbon dioxide bubbles.

Limestone can be processed into various products, per different standards. These products are widely used in many industries. The following are several main products and their applications after limestone processing:

Portland cement

After the limestone is crushed, it is mixed with clay and other materials. The mix is then crushed, screened, and ground to the right size. The powdered materials are sent to the rotary kiln. They are calcined at about 1450°C to form cement clinker. After adding enough gypsum, the clinker is ground into a very fine powder. This is the finished cement.

Building Stone

Cheap limestone can improve stability and cut costs in civil buildings. So, it is a good material for foundations and walls.

Glass

To make glass, mix limestone with soda ash (Na2CO3) and quartz (SiO2). Then, melt it at high temperature. This produces calcium silicate (CaSiO3) and carbon dioxide (CO2), thus making ordinary glass.

Iron ore smelting additives

Limestone is used in iron-making. It removes sulfur by removing silicon dioxide (SiO2) from iron ore. It forms low-melting calcium silicate (CaSiO3). This helps remove impurities from molten iron.

Quicklime (CaO)

Limestone is calcined and decomposed at 900°C – 1300°C to produce quicklime (CaO). This process is usually completed in a shaft furnace or a rotary kiln. It can be used as a building material, desiccant, silent explosive, and dehydrating agent in food and medicine.

Calcium hydroxide (Ca(OH)2)

Quicklime is digested with water to make calcium hydroxide (Ca(OH)2). It is also called slaked or hydrated lime. This step can be done in digesters designed for it. They control the temperature and humidity. It is used to make Bordeaux mixture for pesticides, improve acidic soils, treat acidic wastewater, etc.

Ground Calcium Carbonate (GCC)

Limestone from the mine is first crushed. Then, it is ground into a fine powder by a ball mill or other grinders. An air separator classifies the powder to ensure the right particle size. It has a high chemical purity, is inert, and thermally stable. So, it is a good filler for papermaking, plastics, rubber, coatings, and other industries.

Light Calcium Carbonate (PCC)

Chemical preparation: High-purity limestone is used as the starting material. Quicklime is obtained by calcining limestone. Quicklime is digested to obtain calcium hydroxide slurry. Calcium hydroxide is precipitated. It turns into calcium carbonate crystals in a carbon dioxide atmosphere. Finally, light calcium carbonate products (PCC) are made through filtering, washing, and drying.

Its fine particles and large surface area make it suitable for many fields. These include rubber, plastics, papermaking, building materials, inks, and daily chemicals.

Foundry Sand

Select limestone with a suitable particle size for crushing and screening. It must meet foundry sand requirements. Add binders and other additives as needed. Then, mix them with the limestone sand. This molding sand outperforms quartz sand. It improves the surface quality and finish of castings. It also reduces the risk of silicosis.

Desulfurization absorbent

Limestone is crushed and ground to a fine powder. This captures SO₂ gas during desulfurization. Limestone powder is mixed with water into a slurry. It is used in wet flue gas desulfurization systems. Powdered limestone can be used as an absorbent in flue gas desulfurization systems. It is mixed with water in the absorption tower to form a slurry. This will desulfurize by reacting with the sulfur dioxide in the flue gas.

Active lime, passivated lime

Active lime is a high-quality metallurgical additive. Passivated lime has good moisture absorption and injection properties. Both are mainly used in the steel industry. They are sintering ore additives and agents for molten iron pretreatment. These include slag-making, desulfurization, and dephosphorization agents.

Pharmaceutical Grade Calcium Carbonate

Only food-grade and pharmaceutical-grade calcium carbonate is used. It meets strict standards. It is a nutritional ingredient in calcium and multivitamin tablets. It also fortifies food.

Food grade calcium carbonate

We use high-purity, food-safe limestone as raw material. We then apply strict quality controls, including ultra-fine grinding, purification, and disinfection. This ensures the product’s safety and purity. It is widely used in the calcium supplement and health food industries. It is in dairy products, beverages, and cakes to boost calcium and improve taste.

The above lists the main types of products after limestone ore processing. Each product is vital in its field due to its unique properties. As science and technology advance, limestone processing tech improves. Its derivatives are more diverse, meeting varied market demands.

Improving the value and quality of limestone

To improve limestone’s value and quality, pre-sort it. Use mineral processing equipment to remove impurities. This will increase the final product’s purity. It will also meet more application needs.

Among them are optoelectronic mineral processing devices. These include ore color sorters and AI sorters.

Color sorters: They mainly use optical sensors to detect color differences in materials. This distinguishes target substances from impurities. The machine will detect any impurities in the limestone. It will use compressed air to blow them off the production line. This method is very effective for removing impurities with significantly different colors.

Artificial Intelligence Sorting Machine: They use more advanced tech than traditional color sorters. This includes machine vision and deep learning. They can classify by color. They can also find and remove impurities. They do this using multi-dimensional features like shape, texture, and gloss. After training, the AI can recognize small, complex differences. It handles impurities that are similar in color to limestone but are of a different composition.

When choosing suitable equipment, mining companies need to consider the following factors:

The impurities in the limestone and their traits (color, shape, density, etc.); the production line’s speed and capacity; and the budget and tech support.

Also, it may be necessary to pre-treat the limestone, based on the actual situation. This includes crushing and screening it to ensure the best sorting. Finally, regularly calibrate and maintain the sorting equipment. This ensures its stable, long-term operation and high performance.