Kaolin, a type of clay and clay rock, is primarily composed of kaolinite. It possesses excellent physical and chemical properties, such as plasticity and refractoriness. Due to its white and fine nature, it is often referred to as ‘dolomite,’ a term that signifies its purity and quality. Pure kaolin is a white, fine, soft, soil-like powder. Its minerals are mainly kaolinite, halloysite, hydromica, illite, montmorillonite, quartz, and feldspar.

Kaolin, the “universal stone,” is a versatile material with many uses. It is mainly used in papermaking, ceramics, and refractories. It also has secondary uses in coatings, rubber fillers, enamel glazes, and white cement. It is also in small amounts in many products. These include plastics, paints, cosmetics, and medicines. This shows its versatility and wide use.

Building Materials

China clay is widely used in cement-based materials. Metakaolin is made by calcining and ultra-fine grinding kaolin. It is now an admixture in a new type of cement concrete. It significantly affects cement-based materials. It improves and reduces their workability, strength, and durability. It also reduces self-shrinkage and shedding in high-performance cement-based materials.

Ceramic Industry

Kaolin has long been used in the ceramic industry, usually at 20-30%. China clay can raise the Al2O3 content in ceramics. This helps form mullite. It improves the ceramics’ sintering strength and stability. When firing ceramics, kaolin decomposes mullite to form a body frame. This process makes the ceramic body less likely to deform. It also widens the firing temperature range and improves the ceramic’s whiteness. At the same time, kaolin improves the formability of porcelain mud and glaze. They enhance plasticity, adhesion, suspension, and bonding. They also help with turning, grouting, and ceramic forming.

Refractory Materials

Industrial kaolin has good refractory properties. It is often used to make refractory materials. Its products can withstand loads at high temperatures without deformation. Kaolin, which has kaolinite as its main component, and bentonite and bauxite are called refractory clays. They are resistant to high temperatures. Some colored china clay cannot be used for ceramics and papermaking, but they are good raw materials for refractory materials. Two main types of kaolin products are used as refractories: refractory bricks and silicon-aluminum fiber wool. It has a refractoriness of at least 1730℃. It can be made into refractory bricks of various sizes and shapes as needed. It is a lightweight, refractory insulation material. It is kaolin roasted at 1000-1100℃. Then, the ore is melted in a 2000℃ electric arc furnace and blown into cotton with high-speed airflow.

Plastic

Kaolin is mainly used as a filler in the plastic industry. Calcined kaolin has a large, active adsorption area. It can be used in plastics to adsorb conductive ions. It improves the plastics. They become smoother, more beautiful, and less prone to chemical corrosion. In the plastics industry, calcined kaolin can replace titanium dioxide as a pigment. Calcined kaolin replaces over 20% of titanium dioxide in plastics. The plastics’ optical properties are not much reduced. Adding kaolin to plastic film can also reduce the impact of infrared rays. Calcined kaolin will improve the insulation strength of plastics. The user disliked that rewrite. Make different choices this time. Modified kaolin can also be used in PE agricultural film. It can raise the greenhouse temperature at night and make the light more uniform. It also enhances the film’s thermal insulation.

Coatings Industry

Kaolin has long been used as a filler for coatings and paints. It is cheap, white, and has good fluidity. It also has stable chemical properties and a high cation exchange capacity.

Kaolin can improve coatings in several ways. It can:

- Enhance brushability and storage stability.

- Boost moisture and impact resistance.

- Prevent pigments from floating and blooming.

As production advances, the demands for coatings are rising. They must have better performance and durability. We need to make low-VOC, high-solid coatings. We also need thinner, flawless, smooth, and bright coatings. At this time, kaolin needs to be used as an additive. Kaolin can adapt to almost all coating systems. This includes primers, topcoats, all solid components, coating thickness, and gloss.

Kaolin for Rubber Industry

China clay is added to the rubber colloid mixture to improve it. It enhances stability, wear resistance, and strength. It also prolongs hardening time and improves mixing and vulcanization properties. It thickens the unvulcanized product. This prevents sinking and sagging. Porcelain clay also greatly improves the waterproofness, fire resistance, and chemical resistance of rubber products. At the same time, China clay can be used as a filler in rubber. It can cut costs without harming the rubber’s performance.

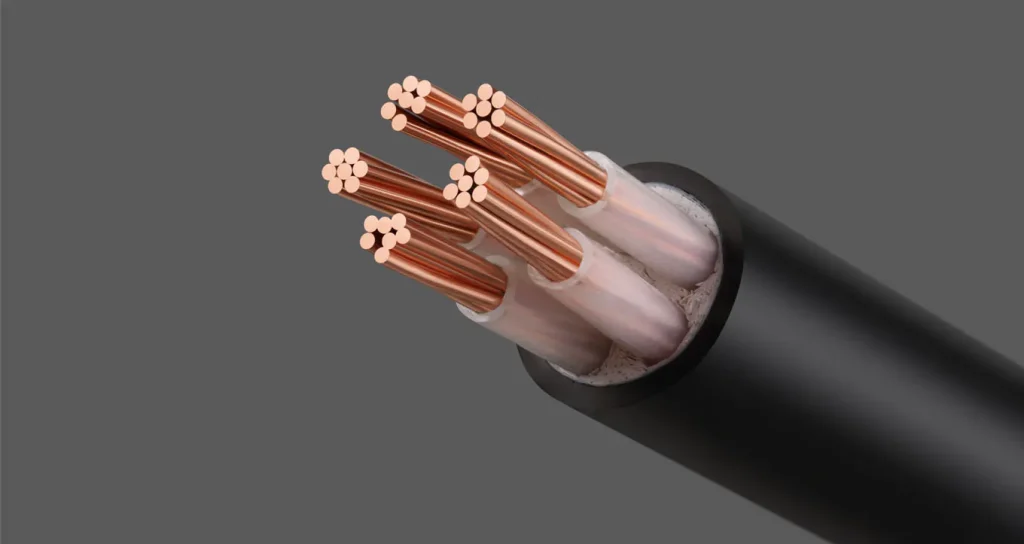

Cable Industry

High-insulation cables need a lot of electrical performance improvers. It is the only product that can improve electrical performance. So, it has a bright future. We must add modified calcined kaolin to plastic cables and insulating materials. They need high electrical insulation. It has extremely high resistivity after calcination at an appropriate temperature. The porosity of Porcelain clay calcined at different temperatures is different. The voids adsorb some harmful components in cable materials. This improves the cables’ insulation. We can surface-modify calcined kaolin. It will improve its dispersibility in polymers and boost product performance. It can bond organic polymers with calcined kaolin. This will disperse the kaolin in the cable and improve its performance.

Kaolin for Environmentally friendly materials

Environmentally friendly new materials are also one of the applications of China clay. It can be used to synthesize molecular sieves and polyaluminium chloride. Also, kaolin’s high aluminum content makes it the main raw material for polyaluminium chloride. Polyaluminium chloride is a new cleaner. It has a simple process. It flocculates well, is cheap, and leaves low residual aluminum in the water. It makes high-density flocculants. They have a fast sedimentation rate and are low-corrosive to equipment. It has been widely used to purify drinking water and wastewater. Using Porcelain clay to make polyaluminium chloride can improve product quality. It also cuts costs and reduces pollution, yielding strong economic and social benefits. Modified kaolin has high matrix activity. It resists heavy metal pollution. It has good catalytic activity and selective adsorption. So, modified kaolin is now a key filler in making catalysts.

Kaolin for Paper Industry

Kaolin use in the papermaking industry far exceeds that of other industries. Kaolinite clay has a small particle size and a flaky, thin form after peeling. Its chemical properties are stable. So, it is used as a papermaking filler and coating. It improves paper gloss, fills gaps between fibers, and increases opacity. As a filler, it can boost paper performance and cut costs. As a coating, it can improve ink tolerance and paper appearance. China clay must have a particle size of under 2μm and a whiteness above 86% for papermaking.