Graphite negative electrode is a common negative electrode material in electrochemistry. Lithium-ion battery research is a key focus. Graphite anode material has a low charge and discharge voltage. It is safe and cheap. So, it is the main negative electrode in commercial lithium-ion batteries. However, its poor solvent compatibility and high-current performance limit use. Co-embedding solvent molecules during the first charge and discharge can cause graphite layers to peel off. This greatly reduces the electrode’s service life and is a major bottleneck for its industrial use. The main way to solve this problem is to modify its surface. Surface modification can improve the electrode’s capacity, efficiency, and cycle performance.

At present, the surface modification of graphite negative electrode is mainly includes: mechanical ball milling, surface oxidation and halogenation, surface coating and element doping.

Mechanical ball milling

Mechanical ball milling is a method that physically change the structure and morphology of the surface of the graphite negative electrode. By increasing surface area and contact area to improve the efficiency of storage and release of lithium ion.

Reduce particle size:

Mechanical ball milling can significantly reduce the particle size of graphite particles. Smaller particle size is conducive to the rapid diffusion of lithium ions and improves the rate performance of the battery.

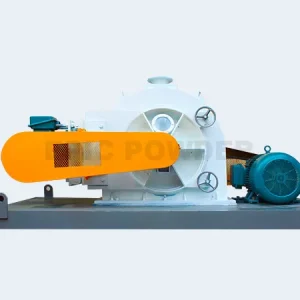

Related equipment

Introduce new phase

During ball milling process, graphite particles may undergo phase changes due to mechanical forces. The new phases can provide more lithium storage sites and improve the lithium storage capacity of graphite.

Increase porosity

Ball milling can generate a large number of micropores and defects on the surface of graphite particles. These pore structures can serve as fast channels for lithium ions, to improve the diffusion rate of lithium ions and the charging and discharging efficiency of the battery.

Surface oxidation and halogenation

Oxidation and halogenation can improve the chemical properties of graphite anode materials at the interface.

Surface oxidation

Surface oxidation usually includes gas phase oxidation and liquid phase oxidation.

Gas-phase oxidation means reaction of graphite with oxidant, such as air and CO2, at the gas-solid interface. This reaction can reduce the active points on graphite surface and reduce the loss of initial irreversible capacity. At the same time, more micropores and nanopores are generated to increase the storage space for lithium ions, it is beneficial to improve the reversible capacity, and then improve the performance of graphite negative electrode.

Liquid phase oxidation refers to the reaction of graphite with solutions of strong chemical oxidants, such as HNO3, H2SO4 and H2O2, this reaction can improve the electrochemical property of graphite negative electrode.

Surface halogenation

Through halogenation treatment, a C-F structure is formed on the surface of natural graphite, it can enhance the structural stability of graphite and prevent the graphite flakes from falling off during the cycle. At the same time, halogenation treatment can also reduce internal resistance, increase capacity and improve charge and discharge performance.

Surface coating

Carbon material coating

With coating amorphous carbon on outer layer of graphite can make a C/C composite material with a “core-shell” structure, this can avoid the direct contact between solvent and graphite, and prevent graphite layer from peeling off caused by the co-embedding of solvent molecules.

Coating of metal and its oxide

Coating of metal and its oxide is mainly achieved by depositing a layer of metal or metal oxide on the graphite surface.

Powder modification related equipment

Element doping

Element doping refers to the targeted addition or loading of certain metals or non-metals into graphite materials, this method can improve the insertion/extraction capability of lithium by changing the microstructure of the material, and then improve the lithium storage capacity and cycle stability of graphite.

Surface modification technology improves the efficiency of storing and releasing lithium ions and the cycle performance of graphite negative electrodes, thereby improving the storage capacity. Qingdao Epic Powder Machinery Co., Ltd. is a professional powder equipment manufacturer. The products include: jet mills, ball mill, air classifiers and modifiers. Surface coating equipment from Qingdao Epic includes: pin- mill modifier, turbo- mill modifier, three-roller modifier and multi-rotor -mill modifier.

If you have any related needs or questions, please contact Qingdao Epic directly.