What is ground calcium carbonate?

Ground Calcium Carbonate (GCC) is a natural mineral. Its versatile properties make it useful in many industries. It comes from limestone, marble, or chalk. They are mostly calcium carbonate (CaCO3). Grinding these raw materials creates fine calcium carbonate particles. They are suitable for construction, plastics, rubber, paints, and pharmaceuticals. GCC is valued for its ability to improve products. It makes them more durable, bright, and opaque. It is also a cheap filler.

Feedstock for the production of ground calcium carbonate powder

Limestone

Calcium carbonate from the lake and sea, after losing water, is compressed and cemented to form a rock called limestone. Its Mohs hardness is less than 3, which is a medium hardness ore. In Egypt, Pakistan and other countries have a large number of mineral deposits. So, these two countries mostly use limestone to make heavy calcium carbonate.

Calcite

Calcite is a calcium carbonate mineral. It’s found in natural calcium carbonates. Therefore, calcite is a widely distributed mineral. Calcite has a variety of crystal shapes. Their aggregates can be clusters of crystals. Or, they can be granular, massive, fibrous, stalactite, or earthy.

Marble

Its main component is calcium carbonate, accounting for more than 50%. It comes in many colors and usually has a distinct pattern. The Mohs hardness is between 2.5 and 5. Its beauty and many colors make it a popular, polished, decorative material for construction.

Chalk

Chalk is a calcium carbonate deposit, a variant of calcite. They formed deep in the ocean floor. Tiny plankton settled to the seafloor and were compressed. The world-famous origins include Essex County, New York, USA and Jiangxi Province, China.

What are the applications of ground calcium carbonate powder?

Rubber industry

Ground calcium carbonate (GCC) is popular in the rubber industry. It has many useful properties. GCC is commonly used as a filler in rubber formulations. It improves rubber’s mechanical properties, like tensile strength and tear resistance. This is particularly important in products like tires, seals, and gaskets. As a filler, GCC can reduce the overall production costs of rubber products. It is often cheaper than other fillers. So, manufacturers can cut costs while keeping quality. Incorporating GCC can enhance the processing characteristics of rubber compounds. GCC can improve the surface finish of rubber products. This is important for both appearance and function. GCC can improve the thermal stability of rubber compounds. It makes them more heat-resistant and prolongs the product’s lifespan. GCC works with many rubbers, including natural (NR), styrene-butadiene (SBR), and EPDM. This makes it a versatile choice for manufacturers.

GCC can benefit rubber formulations. However, manufacturers must consider its type and amount. Too much filler can reduce flexibility and resilience. The right formulation is key to getting the desired performance in the final product.

Plastic industry

Ground calcium carbonate (GCC) is widely used in plastics. It has beneficial properties and is very versatile.

GCC is a common filler in many plastics, like PVC, polyethylene, polypropylene, and polystyrene. It helps to reduce the production costs by partially replacing more expensive polymers.

GCC can improve plastics’ mechanical properties. These include tensile strength, impact resistance, and rigidity. This makes it suitable for applications requiring durability.

GCC can improve plastics. It can enhance flow and reduce viscosity during extrusion and injection molding. GCC improves the surface finish of plastic products. This is key for their look and function.

GCC improves the brightness and opacity of plastics. It makes them more appealing. This is particularly important in packaging and consumer goods. Ground calcium carbonate can improve plastics’ thermal stability. It makes them more heat-resistant during processing.

GCC is a natural mineral. It’s a more eco-friendly option than some synthetic fillers. Its use can contribute to the sustainability of plastic products.

Paper industry

Ground calcium carbonate (GCC) is a key mineral in the paper industry. It is versatile and widely used. It serves several important functions in the production of paper and paperboard. Here are some key aspects of GCC in the paper industry:

GCC is commonly used as a filler in the paper manufacturing process. It helps to improve the brightness, opacity, and smoothness of the paper. Using GCC can cut the need for costly fiber materials. This will save money.

A key benefit of GCC is its ability to boost the brightness and opacity of paper products. Many papers, like printing and packaging, need high brightness and opacity. They are desirable qualities.

GCC contributes to improved printability of paper. GCC’s smooth surface allows for better ink absorption and distribution. This results in sharper images and text when printed.

GCC can be used with fillers, like titanium dioxide or kaolin clay, to enhance the paper’s properties. Fillers can be mixed to meet the needs of different paper grades.

GCC can affect paper’s tensile strength, tear resistance, and stiffness. Manufacturers often adjust the GCC content to meet application goals.

Coating industry

Ground calcium carbonate has high whiteness and low oil absorption. It can reduce the amount of emulsion required and reduce the cost of latex paint. It can also improve the performance of the coating. GCC is a cheap filler. It can bulk up paints and coatings without much cost. It helps achieve the desired thickness and texture. It enhances coatings’ opacity. This improves coverage and gives a uniform look. Ground Calcium Carbonate is vital to the coating industry. It provides functionality, boosts performance, and is a cheap solution for manufacturers. Its versatility and eco-friendliness make it a preferred choice in many coating applications.

Construction industry

Ground calcium carbonate (GCC) is a popular material in construction. It has many useful properties and benefits. Here are some key aspects of GCC in construction:

GCC is a filler in cement and concrete. It improves workability and reduces the amount of cement needed. This can save costs and cut carbon emissions. Heavy calcium carbonate powder is the main ingredient in concrete for construction. This reduces production costs and increases the toughness and strength of concrete. GCC can be added to asphalt mixtures. It will enhance durability and improve pavement performance. It is a filler in some mortar and plaster mixes. It improves bonding and workability. GCC is often used in paints and coatings to improve opacity, brightness, and texture.

Fireproof ceiling industry

Heavy calcium is also used in the production of fireproof ceilings. It can improve the product’s whiteness and brightness. It can also increase its fire resistance. GCC has inherent properties that contribute to fire resistance. It can improve the fire rating of ceiling materials. It will make them better at stopping the spread of flames and smoke. GCC can enhance the thermal insulation properties of ceiling materials. This is important in fireproofing. It helps reduce heat transfer, protecting structures during a fire. In the production of fireproof ceiling tiles and panels, GCC is often used as a filler material. It can improve their strength and durability. It can also help reduce weight.

Feed industry

Ground calcium carbonate can raise the feed’s calcium content. This improves its quality. Ground calcium carbonate (GCC) is a common mineral in the feed industry. It is mainly used as a calcium source for livestock and poultry. GCC provides a highly bioavailable source of calcium. It is vital for many animal functions. These include bone development, blood clotting, and muscle function. GCC is commonly added to animal feeds as a calcium supplement. It is crucial in diets for laying hens and dairy cows. They need a lot of calcium. GCC can neutralize acidity in feed rations. It will improve the feed’s quality and taste.

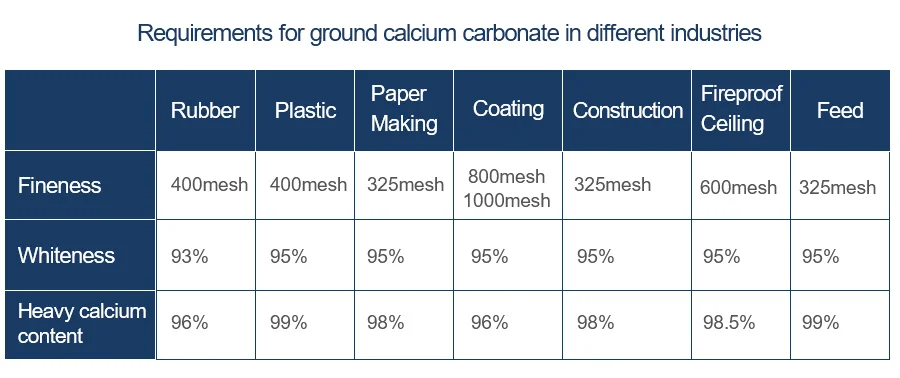

What are the requirements for the application of calcium bicarbonate in different industries?

How to produce ground calcium carbonate of different particle sizes

Producing ground calcium carbonate (GCC) of different particle sizes involves several processes. These include sourcing the raw material, grinding, classifying, and sometimes, surface modification. Here’s a general overview of how to produce GCC with varying particle sizes:

4 types of ground calcium carbonate production lines

Calcium carbonate processing equipment. Calcium carbonate processing equipment includes crushers, pulverizers, bucket elevators, conveyors, feeders, and dust collectors. The main equipment is the pulverizer.

Raymond Mill

Raymond roller mills are mainly used to grind coarse powders. Its feed size is generally 25 to 30 mm, and the output size is 45 to 180 microns. Its passing rate is 99%, which is difficult for other grinding mill equipment. It also has a small footprint, low energy use, and easy maintenance.

It outputs 1 to 30 tons per hour. Different product fineness will affect this. Raymond Mill is widely used and welcomed by users all over the world.

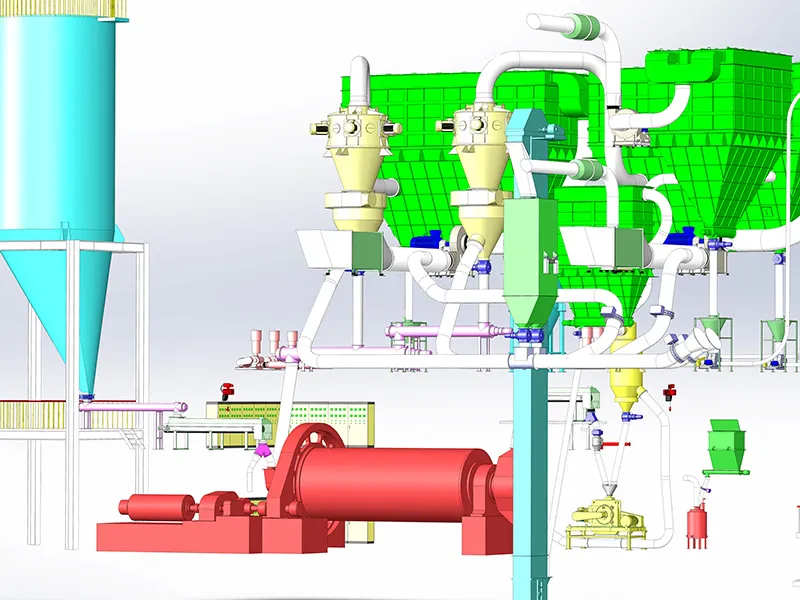

Ball milling and classifying production line for ground calcium bicarbonate

Ball mills are often combined with classifiers to form a complete production line. This mainly produces D97, 5 to 45μm ground calcium carbonate fine powder and ultrafine powder. Different models of ball mill host, its output is also different. Generally speaking, the annual output of the ball mill is between 10,000 tons and 200,000 tons.

Its advanced technology and high-quality, stable products have pleased mid- to high-end customers.

Product Features

- Our calcium grinding and grading tech, equipment, and controls are world-class. The powder is as good as OMIYA’s calcium carbonate. A Malvern laser particle size analyzer confirmed this.

- The grader accurately cuts the particle size. It easily grades -5μm ultra-fine products. It also obtains high-definition micro powders.

- The product has a high fine powder content. Its particles are uniformly shaped. Its particle size can be controlled flexibly.

- The automatic control system can do chain control. It ensures stable, adjustable feeding.

- High grinding efficiency and stable product performance.

- The calcium carbonate line has precision instruments. They ensure accurate records and stable, efficient production.

- The dust emissions are the lowest and the environmental pollution is extremely small.

- The ball mill production line is stable and easy to use. It has simple controls and is easy to maintain.

- We can custom design the ball mill production lines. This will ensure customer satisfaction in every detail.

Micro powder roller mill

As the name suggests, the micro powder roller mill mainly crushes materials by rolling and grinding with its multi-layer ring rollers. It is mainly used to produce ultrafine powder of 8-45μm.

Our common micro powder roller mill models have 21 rollers, 28 rollers and 34 rollers. The greater the number of grinding rollers, the greater its output.

Vertical mill for Ground Calcium Carbonate

A vertical mill is a large grinding machine. It is used in the cement, electric power, metallurgy, and chemical industries. It is often used to produce powders as fine as 10 microns. The vertical mill has a large output and a small footprint.

The vertical mill’s powder is not as good as the ball mill’s. But, it uses 30% to 50% less power. So, the vertical mill is ideal for customers who want low power use.

| Methods | Equipment | Finished product(D97/μm) | Features |

| Dry grinding process | Raymond roller mill | 25-150 | 1.Applicable materials: medium and low hardness;2.Product features: medium and low-end products, suitable for the production of coarse powder;3.Energy saving;4.High yield. |

| Micro powder roller mill | 5-45 | 1.Applicable materials: medium and low hardness;2.Product features: mid-end product, suitable for the production of fine powder;3.Low energy consumption;4.Long service life. | |

| Ball mill | 5-22 | 1.Applicable materials: Various hardness;2.Product features: medium and high-end products, suitable for the production of fine powder;3.The finished product is in good shape;4.Stable and reliable operation;5.High energy consumption. | |

| Vertical mill | 10-45 | 1.Applicable materials: Various hardness;2.Product features: medium and high-end products, suitable for the production of fine powder;3.High yield;4.Energy saving and emission reduction. |

We can customize each production line to meet the end product’s needs. These include purity, particle size, and production capacity. It depends on the raw material source, desired product traits, and end-use. That will determine the production line to use.