Fine alumina powder is an essential material for electronic ceramics, electronic glass, lithium battery separators, and high-voltage electrical equipment. It has characteristics such as insulation, high-temperature resistance, high thermal conductivity, and chemical stability. Its end applications cover key fields like integrated circuits, consumer electronics, power engineering, and new energy vehicles. Other applications include flat-panel displays, photovoltaic power generation, and electronic communications.

Fine alumina powder is mainly made from industrial alumina through processes like purification, calcination, grinding, homogenization, and classification. These processes control the crystal morphology, phase transformation, particle size and distribution, specific elements, surface properties, and reactivity. This ensures the powder has insulation, high-temperature resistance, high thermal conductivity, and chemical stability. It meets the specific material application needs of various downstream industries.

Electronic Ceramics

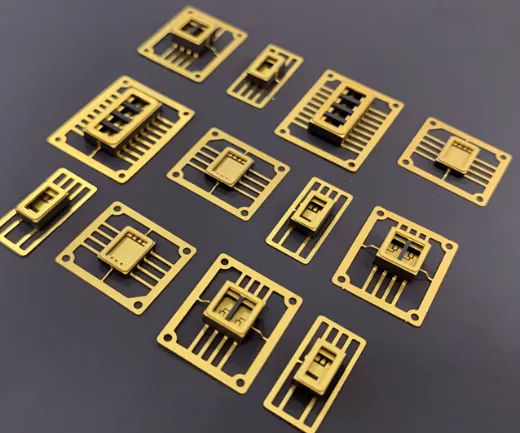

Fine alumina is used to produce various electronic ceramic substrates, ceramic packaging materials, vacuum tube shells, HTCC ceramics, and wear-resistant, high-temperature ceramic parts. It can be widely applied in forming processes such as casting, dry pressing, isostatic pressing, rolling, hot-pressing, and slurry molding. Fine alumina powder is the main component in most electronic ceramic powder formulas. Therefore, the quality and stability of fine alumina directly determine the quality and reliability of electronic ceramic devices.

Electronic and photovoltaic glass

Fine alumina powder is one of the main raw materials for producing electronic glass and photovoltaic glass. Cover glass and substrate glass are typically formed by overflow casting of molten glass, with fine alumina being a key component in the molten glass. It is second only to quartz powder in usage and serves as an important structural functional material. Fine alumina enhances the glass’s toughness and light transmittance, improves chemical stability, and reduces the expansion coefficient. This stabilizes the glass’s performance and provides excellent insulation properties.

High voltage electrical appliances

High-voltage and ultra-high-voltage electrical equipment are widely used in transmission and transformation devices. They are an essential part of power grid construction. Fine alumina, with insulation and heat resistance, is used in insulating materials for high-voltage electrical equipment. It plays a role in both thermal conductivity and insulation in the transmission system.

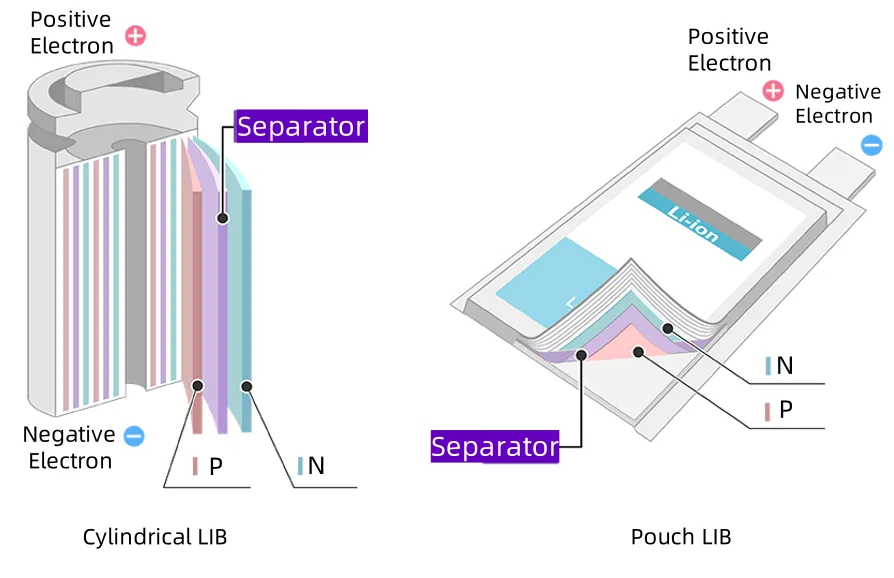

Lithium battery separator

Fine alumina is a key material for lithium battery separator coatings. The main raw materials, polyethylene and polypropylene, have relatively low melting points and poor thermal stability. At certain temperatures, they can shrink or even rupture, causing short circuits in the battery. Coating the separator on one or both sides significantly improves high-temperature stability. This reduces safety risks like electrode contact, combustion, and explosion due to thermal shrinkage. After coating, the separator thickness increases, and both stability and lifespan are significantly improved. Fine alumina coatings on lithium battery separators enhance thermal shrinkage resistance and ensure battery safety.

Grinding and polishing

Alumina powder for polishing and grinding is mainly used as a grinding medium for semiconductor single crystal silicon wafer polishing materials.

High thermal conductivity material

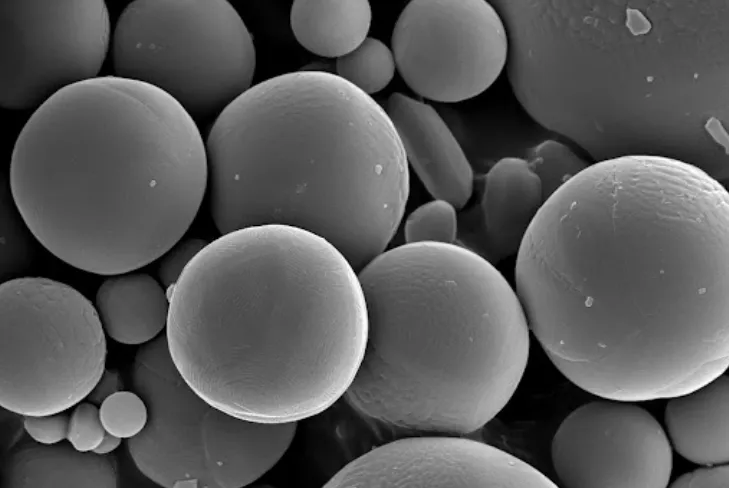

Spherical alumina is an excellent thermal interface material, widely used in emerging fields such as communications, new energy vehicles, integrated circuits, renewable energy, and defense. It is applied in industries like thermal conductive silicone fillers, thermal conductive resin fillers, thermal electronic packaging, and LED plastic fillers. It effectively enhances the insulation and heat dissipation performance of electronic products, improving their efficiency and lifespan.

Refractory Materials

Alumina powder for refractory materials can be used in both monolithic and shaped refractories. It is particularly applied in fine alumina products for ladle breathing bricks, improving the service life of ladles and other equipment.

Conclusion

In summary, fine alumina powder plays a crucial role across a wide range of industries. From electronic ceramics and glass production to energy storage and thermal management, its exceptional properties—such as insulation, high-temperature resistance, and stability—make it an indispensable material. As technology continues to evolve, the demand for high-performance fine alumina will only grow, reinforcing its importance in modern industrial applications.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !