In fine powder preparation, choosing the right grinding method is crucial. Ball mill and air jet mill spheronization are two common fine powder techniques. Each has different working principles and application scopes. Ball mill is widely used for its simplicity and adaptability. Jet mill spheronization offers high energy and excellent spheronization. It shows advantages in high-purity, ultra-fine powder production. To compare their suitability, we can analyze several key aspects.

Precision and particle size control

High-speed air jet mill spheroidization method: This method can achieve finer particle size control and higher particle size uniformity by precisely controlling the airflow speed, collision frequency and time. It is particularly suitable for fine powders that require strict particle size distribution. For example, powders used in the electronics and pharmaceutical industries, because these fields have extremely high requirements for the particle size and shape of powders.

Ball mill: Although the particle size can be controlled by adjusting the grinding time and the size of the medium, the particle size distribution is often wide, and it is difficult to achieve the accuracy of the high-speed airflow impact spheroidization method. In addition, long-term grinding may lead to the production of too fine particles or even agglomeration.

Affecting the performance of the final product.

Powder properties

High-speed air jet mill spheroidization method: It can effectively reduce the surface roughness of the powder and improve the sphericity of the powder. This is crucial for applications that require good fluidity and reduced bulk volume. For example, in lithium-ion batteries, the use of spherical graphite can significantly improve battery performance.

Ball mill method: It may cause damage to the powder surface, forming irregular shapes and increasing surface activity. This may not be the best choice in some cases, especially in fine powder applications that require low surface area and high purity.

Impurities and Purity

High-speed airflow impact spheroidization: Operates in a pollution-free environment, effectively maintaining powder chemical purity, especially for high-purity materials.

Ball milling: Prolonged mechanical friction may cause equipment wear, introducing metal impurities that compromise powder purity, particularly in impurity-sensitive materials.

Energy consumption and cost

High-speed airflow impact spheroidization: Though requiring higher initial investment and energy consumption, its efficiency and high-quality output for premium fine powders may offset these costs.

Ball mill: Lower initial costs, but long-term operational expenses (e.g., energy, maintenance) and potential quality loss may render it less economical for certain fine powder production.

Application Areas

High-speed air jet mill spheroidization method: more suitable for electronics, medicine, high-end chemical industry and other fields. These fields have extremely high requirements for the sphericity, purity and fluidity of powders.

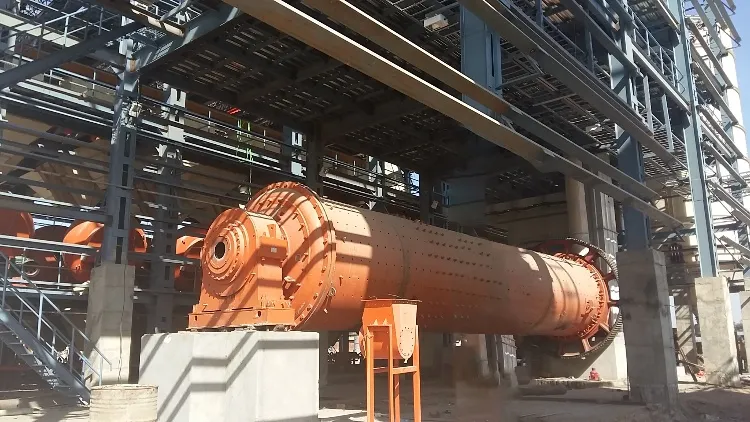

Ball milling method: suitable for industries that are not so strict on particle size requirements or are sensitive to large-scale production costs, such as the preparation of certain ceramics and building materials.

Conclusion

In conclusion, jet mill spheronization shows clear advantages in fine powder preparation. It is ideal for high purity, high sphericity, and precise particle size control. Ball milling suits cost-sensitive applications with less strict size requirements. Method selection depends on product needs, budget, and production scale.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. We have pin mill, turbo mill ,ball mill and air jet mill ,etc.Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !