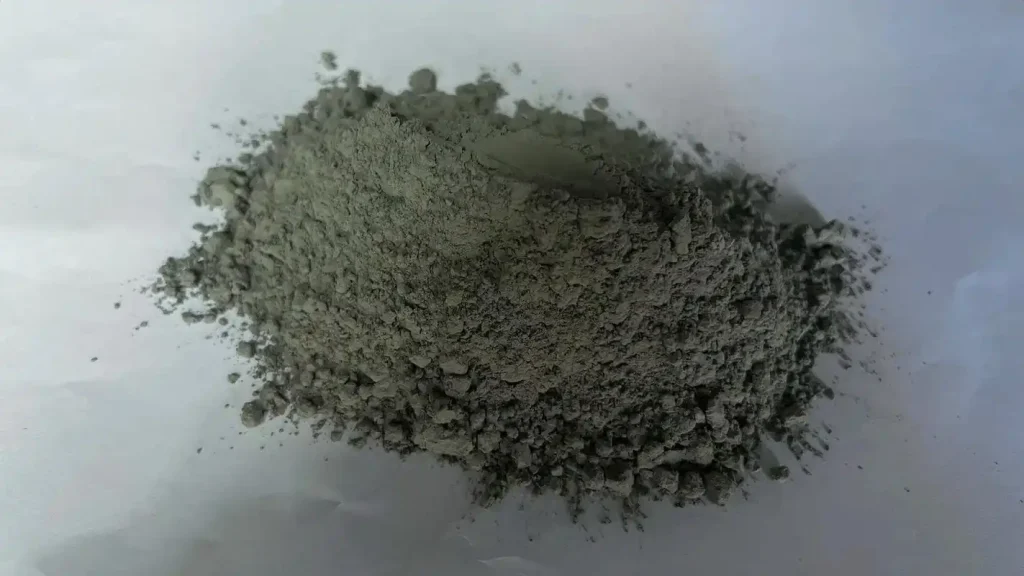

Classification of fly ash is an important process in understanding its properties and potential applications in various industries. Fly ash is a byproduct of burning coal in power plants. It can be categorized by its chemical composition, physical traits, and reactivity.

Fly ash, as an industrial by-product, is closely related to the combustion of coal. It mainly comes from the power, heat, and supply industries. It also comes from other industries that use coal-fired facilities. Fly ash mainly contains SiO2, Al2O3, Fe2O3, CaO, SO3, Na2O, K2O, and carbon. It has a porous structure and is volcanically active. Fly ash can be divided into many types based on its source and chemical composition. The most common classification is the ASTM type C and type F fly ash. The CaO content in type C fly ash is as high as 30% to 40%, while the CaO content in type F fly ash is generally between 1% and 12%.

Classification of fly ash

Type C fly ash: It has a high CaO content. It is usually from burning lignite or sub-bituminous coal. Type C fly ash has cementitious properties and can be used in the production of cement.

Type F fly ash: Type F fly ash has a low CaO content. It is usually from burning bituminous or anthracite coal. This type of fly ash has pozzolanic properties and is often used as an admixture for concrete.

High-aluminum fly ash and ordinary fly ash: My country divides fly ash into two types based on its alumina content. They are high-aluminum fly ash and ordinary fly ash. High-aluminum fly ash has 45% to 65% Al2O3. Ordinary fly ash has less than 27% Al2O3.

Classification by particle size: Fly ash can also be classified into different grades according to its particle size, which directly affects its application effect in concrete.

The role of fly ash in cement

Using fly ash in cement and concrete boosts their performance. It also helps recycle resources and protects the environment. The following are the main functions of fly ash in cement:

1. Improve concrete workability: Adding fly ash can make the mix more fluid, cohesive, and water-retentive. This makes it easier to pump and cast.

2. Reduce temperature rise: Adding fly ash can cut cement use. Its hydration releases little heat, reducing the heat of hydration. Thus, the temperature rise of concrete during construction is reduced. This can significantly reduce temperature cracks.

3. Improve durability: Secondary hydration improves concrete’s density and its interface structure. At the same time, due to the secondary reaction, the amount of calcium hydroxide that is susceptible to corrosion is reduced. Thus, adding fly ash can make concrete more impermeable and resistant to sulfate corrosion.

4. Reduce deformation: The creep of fly ash concrete is lower than that of ordinary concrete. Fly ash reduces water. So, fly ash concrete shrinks and cracks less than, or about the same as, ordinary concrete.

5. Improve wear resistance: Fly ash can improve concrete’s wear resistance. This is vital for high-wear areas like pavements and industrial floors.

6. Economic and environmental benefits: Using fly ash to replace part of cement can cut costs and CO2 emissions in cement production. This has major economic and environmental benefits.

As an industrial byproduct, fly ash has many advantages in cement and concrete. Using fly ash wisely can improve building materials. It can also support resource sustainability and protect the environment. With better technology and supportive policies, fly ash use has great potential. It is expected to play a bigger role in the future.

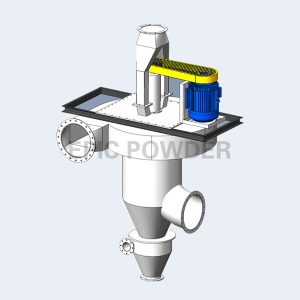

Air classifier for fly ash

An air classifier for fly ash is a special machine. It separates fine particles from coarse ones in fly ash, a byproduct of burning coal. This classifier uses air flow and centrifugal forces. It sorts particles by size and density. The air classifier improves fly ash by optimizing the classification process. This makes the ash suitable for various uses, like making cement and concrete. Removing undesirable coarse particles improves the fly ash. It boosts performance and supports sustainable construction. It does this by promoting the reuse of industrial byproducts.