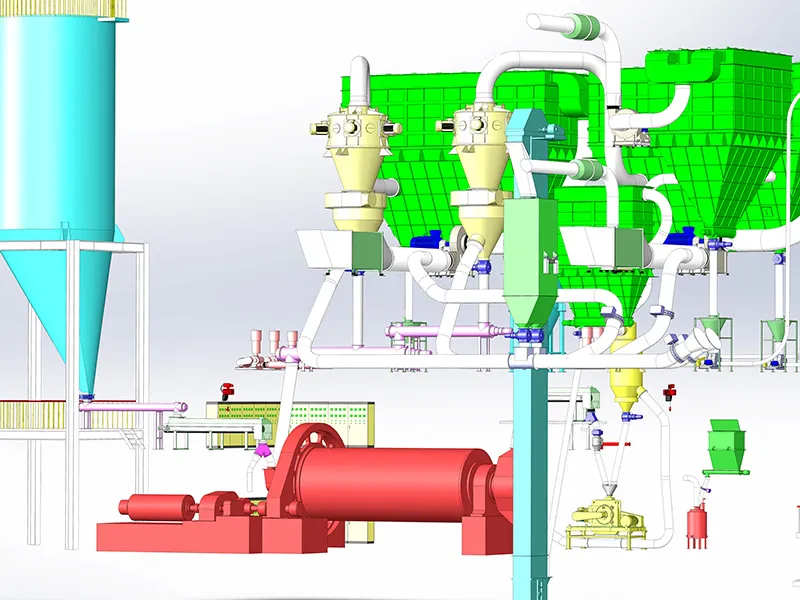

How Does the Classification Process Work in a Jet Milling

A jet milling’s classification process is vital for reducing and separating particle sizes. This is crucial in industries like pharmaceuticals, food processing, and materials science. This process uses high-velocity air jets for fine grinding. It also classifies particles by size and density. Knowing how this process works can improve efficiency, product quality, and energy use. […]

Particle size? Mesh size? How to convert mesh and micron?

[In general, mesh number × aperture (micrometers) ≈ 15000.] For example, a 100-mesh screen has a 150-micron aperture. A 200-mesh screen has a 75-micron aperture. A 300-mesh screen has a 48-micron aperture. A 500-mesh screen has a 30-micron aperture. Below is a conversion between common mesh numbers and particle sizes. Mesh Micron (μm) Mesh Micron […]

How does the jet pulverizer ensure high purity in the grinding process

In the world of particle size reduction, keeping the product pure is key. This is especially true in industries where the final product’s quality matters a lot. The jet pulverizer, a cutting-edge air-based grinding tech, is crucial for keeping the grinding process pure. It uses compressed air to efficiently cut down particle sizes while keeping […]

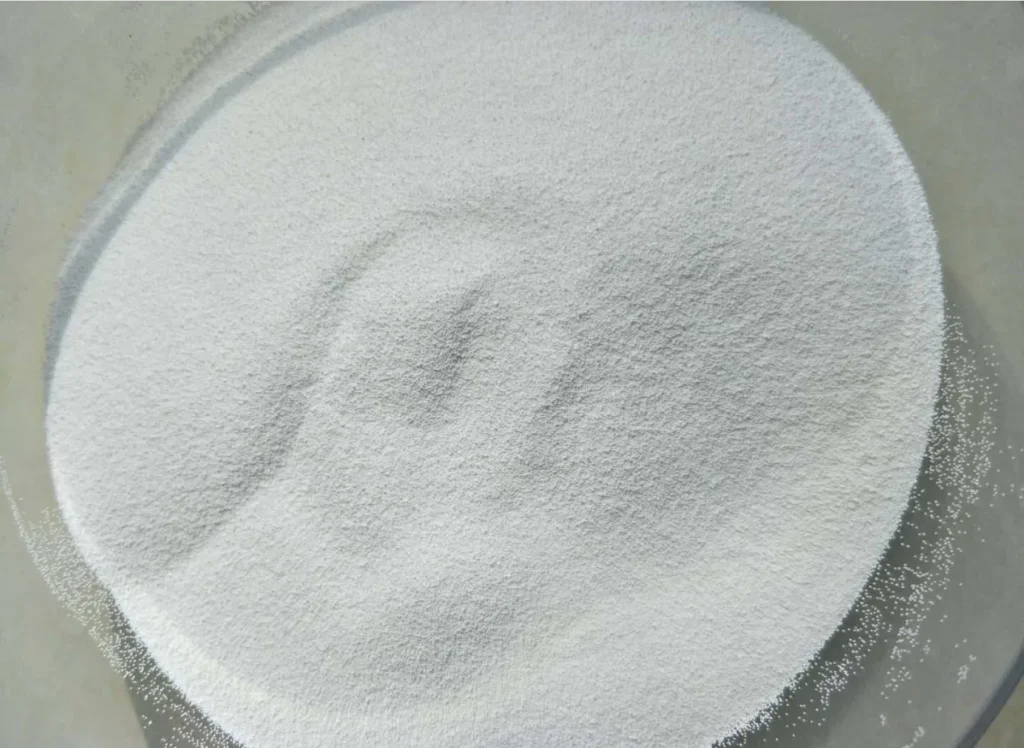

What problems are often encountered in dry grinding of calcium carbonate?

Dry grinding of calcium carbonate makes heavy calcium carbonate. It is a common process. It is widely used. It has a low equipment cost, a simple process, and high output. Its technology is mature and it consumes little energy. However, some problems may arise in production, including but not limited to: Granularity Limitation in Dry […]

How does the jet mill maintain a low grinding temperature?

Jet mills are specialized devices for grinding materials. They are used where fine particle sizes are needed. A key benefit of jet mills is their ability to keep a low grinding temperature during milling. This is crucial for materials that can be sensitive to heat, such as pharmaceuticals and certain chemicals. Mechanisms for Low Grinding […]

Brief Analysis of the Importance of Alumina in Practical Applications

Alumina is a new variety. New varieties are often unfamiliar to most people, but they are also opportunities. Alumina has a very important property: although it seems sufficient, once it is in short supply, aluminum plants will suffer huge losses, or production accident or explosion, even long-term closure. As we all know, aluminum smelters, glass factories, and steel mills are the three major […]

What are the advantages of using a jet mill for heat-sensitive materials

The jet mill for heat-sensitive materials is designed to minimize thermal degradation during the grinding process. Jet mills reduce particle size using high-velocity air or steam. This minimizes heat during milling. This is vital for heat-sensitive materials. They may degrade or lose efficacy at high temperatures. Also, jet milling gives a uniform particle size. This […]

How to choose grinding equipment for paint grinding?

Paint grinding is vital for making high-quality paints and coatings. This technique uses a machine to reduce pigment particles. It aims for a specific fineness and dispersion. This affects the final product’s color, texture, and performance. During paint grinding, we use various equipment. This includes jet mills, ACM mills, ball mills, bead mills, and high-shear […]

Application technology of ultrafine powder in concrete

In concrete, ultrafine powder, a key mineral admixture, helps. It improves the gradation of powder materials and the concrete’s performance. Ultrafine powder boosts concrete’s performance. It also saves energy and reduces emissions. On one hand, adding ultrafine powder can cut cement use. This reduces energy use and carbon emissions in concrete production. On the other […]