What are the main advantages of using jet milling over other particle size reduction methods

Jet milling is a highly effective technique for particle size reduction that offers several distinct advantages compared to traditional milling methods. It is better than traditional methods like ball mill, air classifier mills, or hammer milling. How Jet Milling Works The jet mill is an advanced particle size reduction device. It has a unique working […]

Learn about various ceramic powders in one article

Advanced ceramics excel in many properties. They have mechanical, acoustic, optical, thermal, electrical, and biological qualities. They are used in high-end tech fields like aerospace, electronics, and biomedicine. They are also used in advanced manufacturing. There are many types of advanced ceramics. Each type has its own traits. For example, alumina ceramics resist oxidation. Silicon […]

Jet Mill or Air Classifier Mill: Making the Best Choice

Choosing between a jet mill and an air classifier mill depends on your needs. Jet mills excel at making ultra-fine powders with precise particle size control. They are ideal for low-contamination industries. They use high-speed gas jets to grind particles. They are suitable for dry, hard materials. In contrast, air classifier mills are versatile. They […]

What impact do different classification technologies have on powder purity?

Many technologies classify powders. The most common are screening, airflow, and centrifugal classification. Their effects on powder purity vary. Sieving method The sieving method is to use a sieve to grade the powder, which is suitable for coarse powder grading. If the sieve is intact, it can remove large impurities. It will improve purity. However, […]

What effect does the particle size of barium sulfate have on coatings?

Barium sulfate, as an inorganic pigment, is widely used in the coating industry. It reflects well at 300-400 microns. It prevents light aging from damaging the paint film. It is an efficient white matte stabilizer. Its unique needle-like crystal structure gives it excellent matte properties. It can also enhance the coating’s leveling. Also, barium sulfate’s […]

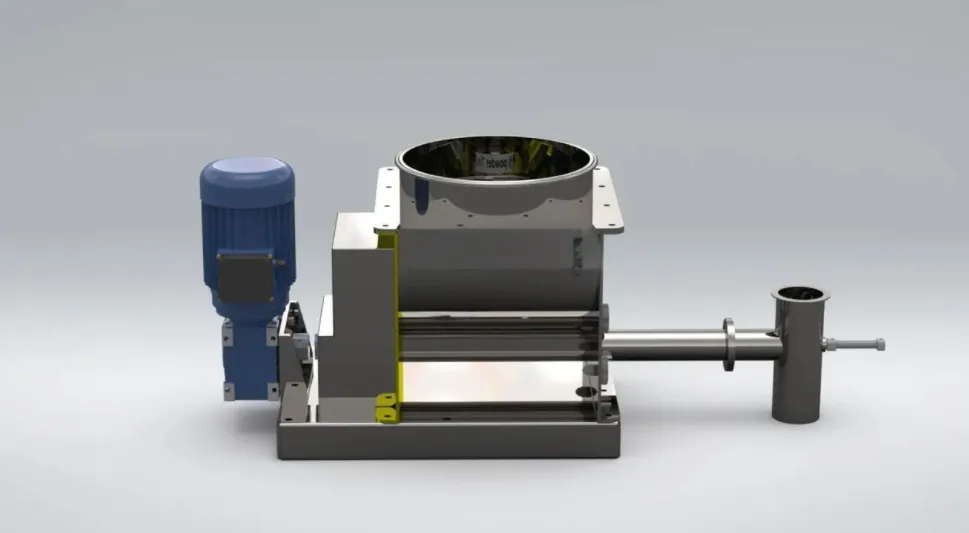

Powder feeding equipment classification and application introduction

Powder feeding equipment is vital. It conveys powder materials to the production process, accurately and evenly. Feeding equipment is vital to the silo system. It also conveys materials over short distances. Due to different purposes of use, it is also called a feeder, a feeder or a discharger. It is usually installed at the silo’s […]

How to improve the agglomeration phenomenon of small particle alumina powder?

Small particle alumina powder has unique properties. It is used in ceramics, chemicals, electronics, and other fields. However, in practical applications, small-particle alumina powder is prone to agglomeration. Agglomeration is when powder particles stick together and form larger clumps. This can happen during the storage, transport, or use of powdered materials. This affects its performance. […]

Detailed analysis of barite industry applications

Barite is the most common barium mineral. It is barium sulfate. It is often found in low-temperature hydrothermal veins, like quartz-baryte and fluorite-baryte veins. It is often associated with galena, sphalerite, chalcopyrite, and cinnabar. Most barite deposits in my country are in Hunan, Guangxi, Qinghai, and Jiangxi. They are mostly huge hydrothermal single mineral veins. […]

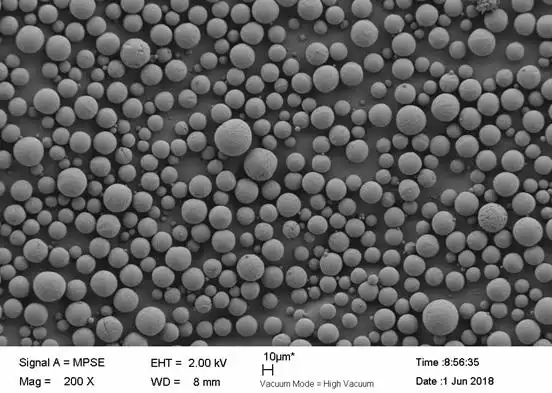

Comparison between ball milling and high-speed airflow method

Comparing the ball milling method and the high-speed airflow method, which one is more suitable for the preparation of fine powders? To compare the ball milling and high-speed airflow methods for making fine powders, we can analyze several key aspects in detail. Precision and particle size control High-speed airflow impact method: This method can achieve […]