The different roles of heavy calcium and light calcium in rubber applications

Calcium carbonate is an important and widely used inorganic salt. Calcium carbonate is usually divided into heavy and light forms. This is based on different processing methods. Calcium carbonate is the most widely used powder filler in the rubber industry. It comes in two forms: heavy and light. Related concepts 1. Calcium carbonate. It is […]

What are the similarities and differences between quartz powder, talc powder and heavy calcium powder?

What distinguishes talc powder, quartz powder, and heavy calcium powder? Firstly, there is a significant difference in feel between the three. Talc powder has a more delicate and smooth texture. Talc, quartz, and heavy calcium powder are non-metallic minerals. They are crucial for both the industry and commerce. They are primarily used as filler. They […]

Preparation and application of high specific calcium hydroxide

High specific surface area calcium hydroxide is a powder. It has a high specific surface area. It is used in many fields, like environmental protection and medicine. There are many methods for making high surface area calcium hydroxide. They include the mechanical, chemical precipitation, microemulsion, and template methods. The mechanical method uses force to break, […]

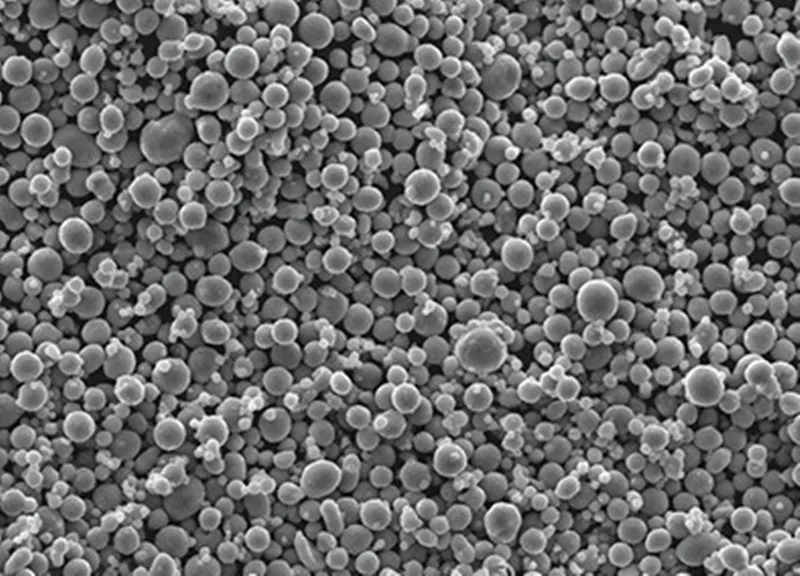

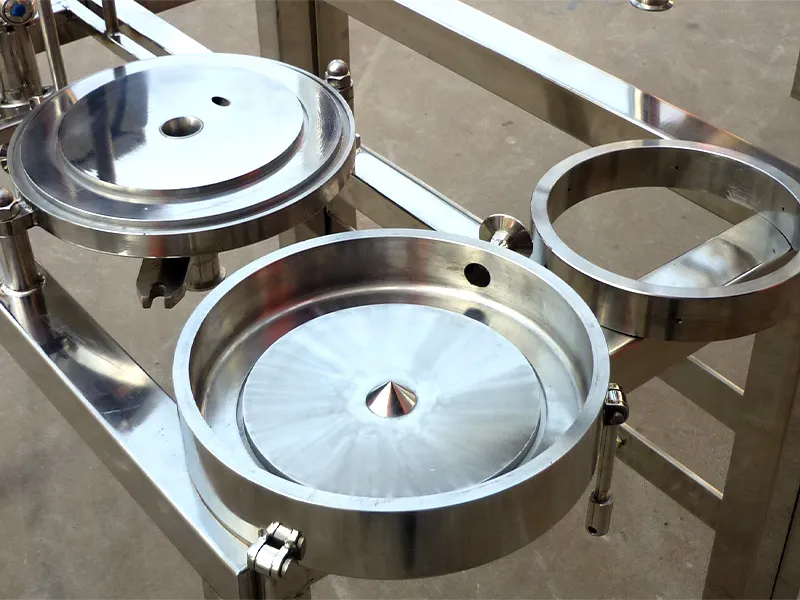

Application of airflow classifier in metal powder industry

The airflow classifier is a widely used equipment in the metal powder industry. By classifying the size of powder particles, it can effectively improve product quality and market competitiveness. This article will introduce the working principle of air classifiers. It will also cover their application areas and advantages. working principle Air Jet Sieve uses the […]

Production technology of heavy calcium carbonate powder for breathable membranes

What is calcium carbonate used in breathable membranes? What are the production difficulties? What is a breathable membrane? A breathable film is microporous. It lets water vapor through but obstructs liquid water. It is primarily used to make health products. It also makes breathable, rainproof cloth and other products. It is used in various fields […]

Application of ultrafine grinding technology in food processing

Ultrafine grinding technology is a new technology developed in the past 20 years. Ultrafine grinding involves using force to crush solids. It does this by overcoming their internal cohesion. It crushes particles from above 3 mm to 10-25 microns. It was developed in the 1970s to adapt to modern times. A high-tech material processing technology […]

What is the use of modified calcium carbonate?

Modified calcium carbonate is calcium carbonate (CaCO3) that has been treated to improve its properties for specific uses. Calcium carbonate is cheap, abundant, and non-toxic. So, it is used in many industries. These include construction, plastics, rubber, pharmaceuticals, and food. Calcium carbonate’s modification mechanism has two types. One is chemical action, the other is physical […]

Application sharing of jet mill in API particle size control

In recent years, research and drug processing have changed. They used to focus on pharmacology but now aim to improve drug effects. Development will focus on refining drug particles. It will make them ultrafine, purify them, and add functions to them. Research and applications are focused on particles below the submicron level. The pharmaceutical industry […]

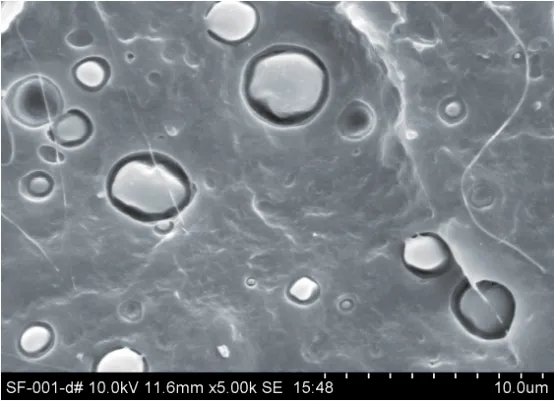

Nano calcium carbonate requires surface modification

Due to the surface effect and hydrophilic and oleophobic properties of nano-calcium carbonate, unmodified nano-calcium carbonate has shortcomings such as dispersion, poor affinity, and easy agglomeration when applied to organic polymers, seriously affecting the quality of the product. , leading to interface defects between the two materials, and the higher the filling amount of nano-calcium […]