Why Pin Mills Are Ideal for Food Grinding Applications ?

In the food processing industry, achieving consistent particle size, preserving product integrity, and maintaining hygiene standards are critical priorities. Among the various grinding technologies available, pin mills have emerged as a preferred choice for food applications due to their versatility, efficiency, and precision. This article explores the unique advantages of pin mills and why they […]

Disc Jet Mill for Medicine : An Innovative Combo for Better Pharma Processing

In modern medicine, drug development seeks higher quality and efficacy. Particle size and distribution critically impact drug performance. Disc jet mill, as advanced grinders, are gaining traction in pharma production. They offer new opportunities to improve drug quality and efficiency. Working Principle of Disc Jet Mill The disc jet mill operates on a unique principle. […]

Application of Air Classifier Mill in Food Grinding

As the food industry evolves, grinding technology becomes increasingly crucial. It affects food quality, taste, nutrition, and efficiency. Consumers demand diverse, refined, and nutritious food. This drives innovation in food grinding technology. The air classifier mill in food grinding stands out as an innovative solution. Its unique mechanism boosts food processing capabilities significantly. Working Principle of Air Classifier Mill The […]

Application fields of conductive carbon black

Conductive carbon black is a typical type of specialty carbon black. It offers high electrical and thermal conductivity. Moreover, it has low production cost and good oxidation stability. It also features low density, enhancing material performance. As a result, it is widely used in conductive plastics. Additionally, it plays a key role in conductive rubber. […]

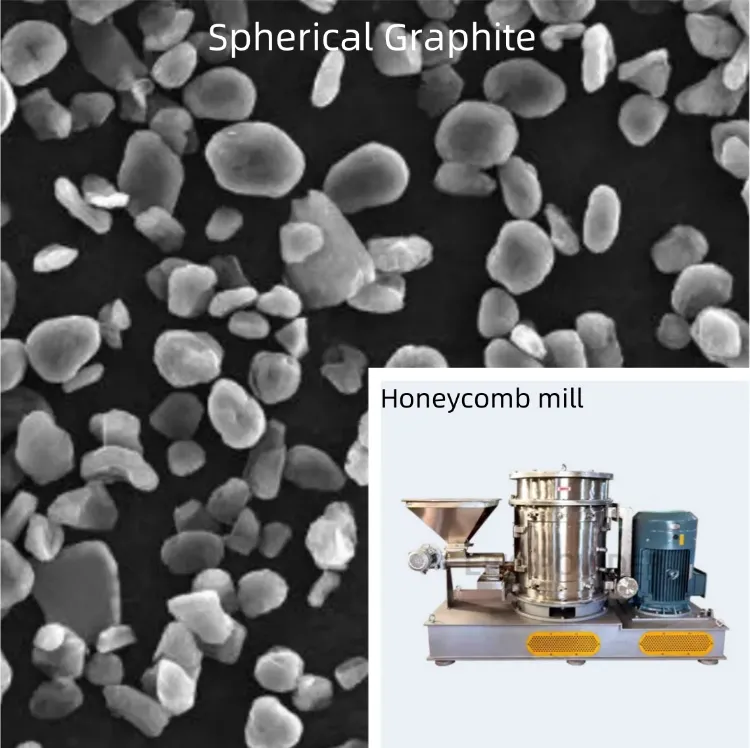

Spherical Graphite Preparation: Key Factors Affecting Particle Morphology

Anode material is a core component of lithium-ion batteries. It determines the rate performance of lithium-ion batteries. It also affects initial charge-discharge efficiency and cycle stability. Natural graphite anodes are made from natural flake graphite. The process includes crushing, spheroidizing, classifying, purifying, and surface modification. They are low-cost, abundant, safe, and non-toxic. They also offer […]

Do you know the application of fine alumina powder ?

Fine alumina powder is an essential material for electronic ceramics, electronic glass, lithium battery separators, and high-voltage electrical equipment. It has characteristics such as insulation, high-temperature resistance, high thermal conductivity, and chemical stability. Its end applications cover key fields like integrated circuits, consumer electronics, power engineering, and new energy vehicles. Other applications include flat-panel displays, […]

Compared with ball mill and air jet mill spheroidization, which one is more suitable for the preparation of fine powders?

In fine powder preparation, choosing the right grinding method is crucial. Ball mill and air jet mill spheronization are two common fine powder techniques. Each has different working principles and application scopes. Ball mill is widely used for its simplicity and adaptability. Jet mill spheronization offers high energy and excellent spheronization. It shows advantages in […]

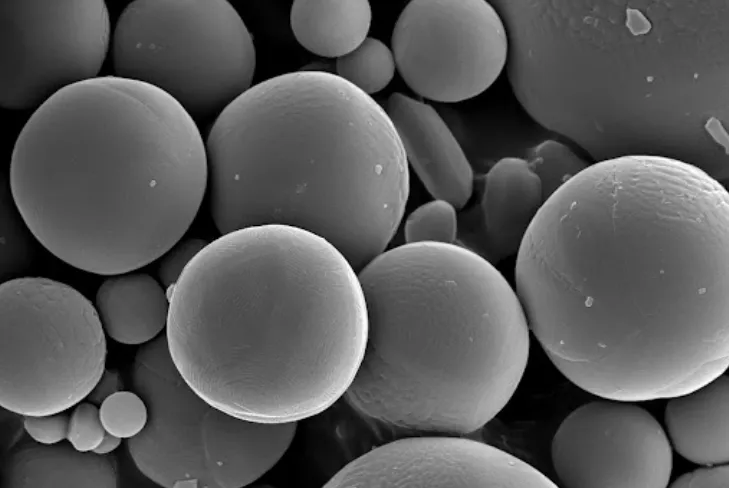

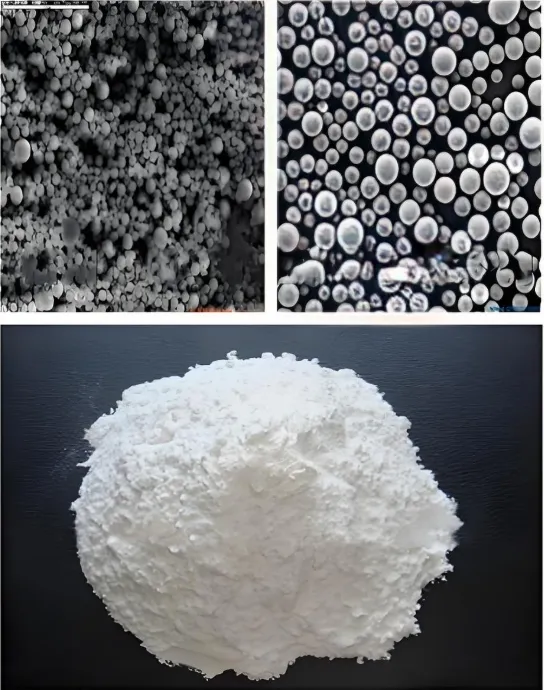

What is spherical silica powder ?

Spherical silica powder is a spherical silicon dioxide material. It has excellent properties and important applications. The particles are regular spheres. Compared to irregular silica, spherical silica powder perform better. It usually has high purity and narrow particle size distribution. It also shows good whiteness. Its flowability is excellent, and dispersion is good. These properties […]

How can powders improve the problem of cosmetics not being skin-friendly?

With the popularity of makeup, powder usage in cosmetics is growing. Cosmetics powders fall into four main categories. These are pigment powders, white powders, filler powders, and pearlescent powders. Pigment powders are used to adjust cosmetic color tones. White powders provide coverage, whitening, and UV protection. Filler powders vary and serve multiple functional roles. They […]