Alumina is a new variety. New varieties are often unfamiliar to most people, but they are also opportunities. Alumina has a very important property: although it seems sufficient, once it is in short supply, aluminum plants will suffer huge losses, or production accident or explosion, even long-term closure.

As we all know, aluminum smelters, glass factories, and steel mills are the three major industries that cannot close the furnace. Their production process requires continuous operation. They can reduce production or simmer the furnace for short time. If the furnace is shut down and restarted, it will incur a huge start cost. This will raise production costs and the risk of accidents, equipment damage, and depreciation. So, the alumina reserve in aluminum plants should be above 20 days. However, due to excess alumina, many firms cut their safety reserve to just eight to ten days. A five-day reduction in the safety reserve will cause a supply shortage downstream. That would be a serious problem.

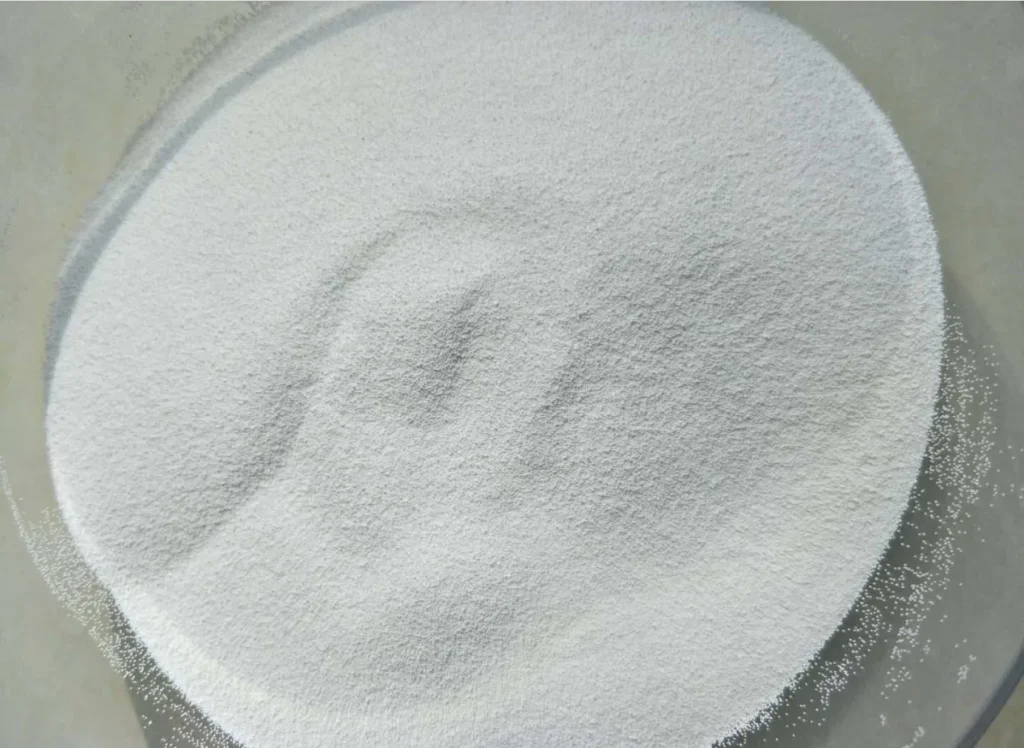

What is Alumina

As a semi-finished product that cannot be seen or touched, aluminum is mainly used in smelting in industrial field. 95% of the raw material for smelting electrolytic aluminum are direct raw material for electrolytic aluminum. Ceramics, tiles and refractory material that we can see everywhere often need alumina. At the same time, alumina can also be made into corundum, which is the artificial sapphire that we often see. A considerable part of the material of artificial gemstones is alumina. Therefore, alumina itself is a raw material, it is connected to bauxite above and electrolytic aluminum applications below.

Alumina Application

Alumina can be made into electrolytic aluminum, then electrolytic aluminum can be made into aluminum processed products. The terminal application fields of aluminum products cover the well-known fields of construction, automotive, electronics and packaging. So alumina or the entire aluminum industry is actually indispensable in our lives. All-aluminum car body, rocket, high-speed rail and aircraft etc, all these high-end products use a large amount of aluminum alloy high-strength material. Alumina, as the upstream of the aluminum industry chain, together with electrolytic aluminum and downstream processing, constructs the entire aluminum industry chain.

With the advancement of technology and the development of industry, the demand for alumina keeps increasing. The electrolytic aluminum industry has shown strong resilience and potential against the backdrop of global economic recovery, and may even become one of the hot areas of investor attention in the future. In addition, continuous support and policy optimization of government will ensure the steady growth of aluminum industry.

What can EPIC Powder do?

Qingdao Epic Powder Machinery Co., Ltd. is a professional manufacturer of powder processing equipment. The products include: jet mill, ball mill, vibration mill, roller mill, various classifiers, surface coating modifiers and related auxiliary equipment, such as dust collector. Qingdao Epic has always adhered to the principle of reliable quality, low price, first-class after-sales service, and the concept of one customer one design. Many years of production experience have enabled Qingdao Epic to have a good research and practice in grinding, classifying and modification of alumina.