The on-site installation construction plan of the bag dust collector mainly includes the following steps

The on-site plan for installing the bag dust collector includes these steps: 1. Equipment inspection and acceptance: Before installation, inspect the bag dust collector. Check that its appearance, size, and model meet the design requirements. Also, ensure its internal components are intact. At the same time, the equipment needs to be tested to ensure that […]

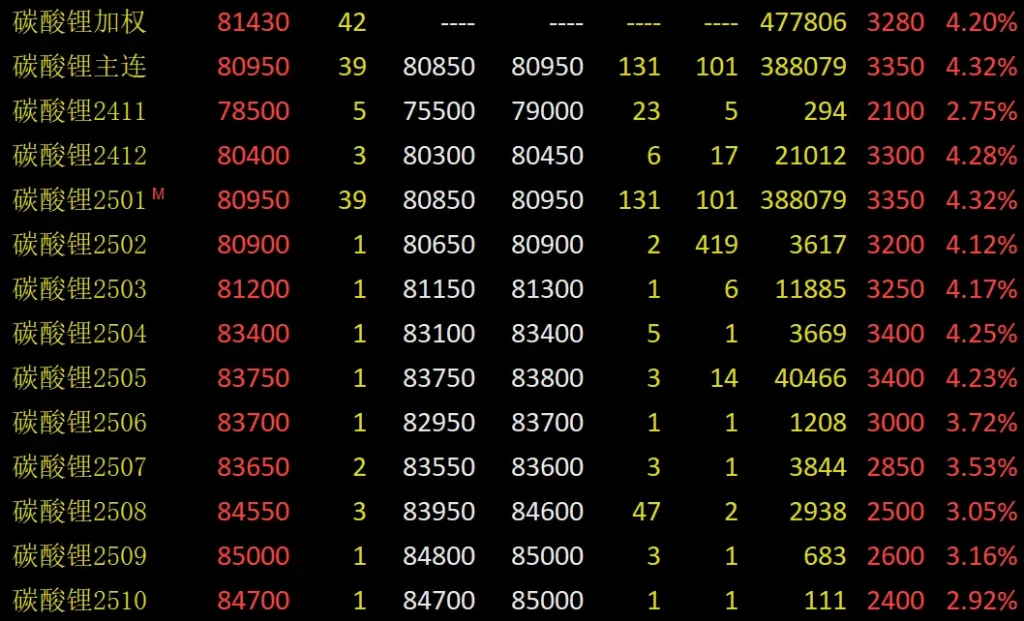

Lithium carbonate price breaks through 80,000 yuan/ton!

On November 11, lithium carbonate futures soared to 80,000 yuan/ton. As of the close of the day, the main LC2501 contract closed at 80,950 yuan/ton, up 4.32%. At the same time, trading volume and open interest rose sharply. The lithium carbonate index added 60,300 lots, a record high. Yu Shuo, an analyst at Chuangyuan Futures, […]

Effect of calcium powder residue content on the processing and performance of PVC products

Calcium powder residue content greatly affects PVC (polyvinyl chloride) products. It impacts their mechanical properties and overall quality. Calcium carbonate is a common PVC filler. It is key to their properties. Impact on the appearance of PVC products Excessive calcium powder residue may cause the gloss of PVC products to decrease, and the color to […]

Surface modification method of non-metallic mineral powder

Surface modification is key to improving non-metallic mineral powders. It enhances their properties and applications. Non-metallic minerals, like talc, kaolin, and calcium carbonate, are used in many industries. These include plastics, paints, ceramics, and pharmaceuticals. However, their properties often need improvement to meet application demands. Surface modification techniques can greatly change the properties of these […]

How Does the Classification Process Work in a Jet Milling

A jet milling’s classification process is vital for reducing and separating particle sizes. This is crucial in industries like pharmaceuticals, food processing, and materials science. This process uses high-velocity air jets for fine grinding. It also classifies particles by size and density. Knowing how this process works can improve efficiency, product quality, and energy use. […]

Particle size? Mesh size? How to convert mesh and micron?

[In general, mesh number × aperture (micrometers) ≈ 15000.] For example, a 100-mesh screen has a 150-micron aperture. A 200-mesh screen has a 75-micron aperture. A 300-mesh screen has a 48-micron aperture. A 500-mesh screen has a 30-micron aperture. Below is a conversion between common mesh numbers and particle sizes. Mesh Micron (μm) Mesh Micron […]

How does the jet pulverizer ensure high purity in the grinding process

In the world of particle size reduction, keeping the product pure is key. This is especially true in industries where the final product’s quality matters a lot. The jet pulverizer, a cutting-edge air-based grinding tech, is crucial for keeping the grinding process pure. It uses compressed air to efficiently cut down particle sizes while keeping […]

What problems are often encountered in dry grinding of calcium carbonate?

Dry grinding of calcium carbonate makes heavy calcium carbonate. It is a common process. It is widely used. It has a low equipment cost, a simple process, and high output. Its technology is mature and it consumes little energy. However, some problems may arise in production, including but not limited to: Granularity Limitation in Dry […]

How does the jet mill maintain a low grinding temperature?

Jet mills are specialized devices for grinding materials. They are used where fine particle sizes are needed. A key benefit of jet mills is their ability to keep a low grinding temperature during milling. This is crucial for materials that can be sensitive to heat, such as pharmaceuticals and certain chemicals. Mechanisms for Low Grinding […]