Diamond Micro Powder: The Core Driving Force of Precision Machining Technology

Diamond, commonly known as “diamond drill,” is a mineral composed of carbon atoms. It is an allotrope of graphite, with the chemical formula C, and is the natural form of what we typically recognize as a diamond. Diamond is the hardest naturally occurring substance on Earth. Diamond micro powder is mainly divided into three types: […]

How to choose ultrafine powder milling process and equipment ?

Ultrafine powder milling technology is called a cross-century high-tech by scientists worldwide. After refinement, material properties change significantly. Optical, electrical, magnetic, and mechanical properties are affected. Thermal, surface, and interface characteristics also change. Extraordinary effects are often achieved in use. Ultrafine powder milling is usually divided into micron-grade, submicron-grade and nano-grade powders. The international scientific […]

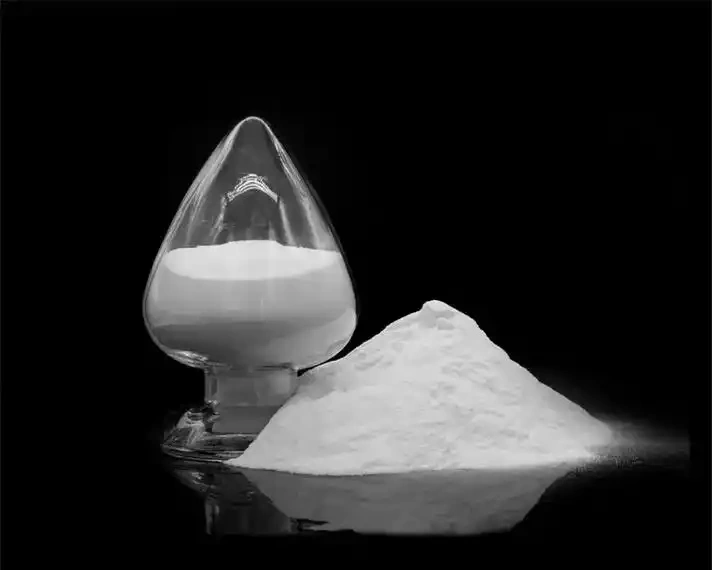

What is White Carbon Black? This article will show you all about white carbon black

White carbon black is modified silicon dioxide, which is a general term for white powdered X-ray amorphous silicic acid and silicate products. It mainly refers to precipitated silica, fumed silica and ultrafine silica gel. It also includes powdered synthetic aluminum silicate and calcium silicate. White carbon black is a porous substance, composed of SiO2·nH2O. Here, […]

Do you know the preparation process of ceramic powder raw materials?

Ceramic powders are the fundamental “cells” in ceramic material R&D and production. Ceramic powder preparation process directly affects the performance and quality of final ceramic products. Advanced technologies enable the synthesis of nano-scale ceramic powders. Traditional raw materials are also being processed with greater precision. These innovations continue to evolve.They are pushing the ceramic industry […]

Application of Air Jet Mill for the Preparation of Lithium Iron Phosphate

With the rapid growth of the new energy industry, lithium iron phosphate batteries have become the new favorite of the market with their advantages such as high safety and long life. In production, Jet mill for Lithium Iron Phosphate play a key role in lithium iron phosphate preparation. As efficient ultrafine grinding equipment, they crush […]

The Research and Application of Modified Silicon-Based Anode Materials

With the evolution of EVs and electronics, lithium-ion batteries require higher energy density. Traditional graphite anodes have a low theoretical capacity of 372mAh/g, limiting energy density improvement. Silicon is abundant, eco-friendly, and has a high theoretical capacity of 4200mAh/g. It is considered a promising next-generation lithium-ion battery anode material. However, severe volume expansion and low […]

Modified heavy calcium partially replaces nano calcium to reduce the cost of silicone adhesive

Silicone sealants contain various fillers. These include silicon dioxide, nano calcium carbonate, wollastonite powder, and heavy calcium carbonate. Nano calcium carbonate is the most common one used. In the domestic sealant market, over 60% of silicone sealants contain nano calcium carbonate. This usage is quite significant. Nano calcium carbonate is a key filler in silicone […]

Advantages of Jet Milling for Producing PE Wax Micropowder

Jet milling is the best way to micronize polyethylene (PE) wax into a fine powder. It offers unique technical advantages and process benefits. The technology is great at making uniform, fine particles that range from 2 to 10 microns. It also keeps the material’s thermal integrity intact. Research shows that jet milling offers great control […]

Six high temperature resistant engineering plastics

Engineering plastics are strong polymer materials. They perform well and are used in many areas. Ultra-high temperature resistant engineering plastics have gained attention for their great heat resistance. Do you know these six ultra-high temperature resistant engineering plastics? Polyphenylene sulfide (PPS) Polyphenylene sulfide (PPS) is a crystalline polymer with outstanding thermal and chemical stability. It […]