How Does an Air Jet Mill Perform in the Ultrafine Grinding of Petroleum Coke for a Precise D97 of 28 Microns?

Understanding Petroleum Coke Characteristics Petroleum coke (petcoke) is a carbon-rich solid derived from the oil refining process. It features a high carbon content, low ash, and variable sulfur levels depending on the source crude. These characteristics make it valuable across industries, especially when processed into fine powders through petroleum coke ultrafine grinding, which enables precise […]

How to Improve Anode Capacity through Advanced Ultrafine Grinding Technology?

The Science Behind Particle Size and Morphology In my 20+ years of experience with powder processing, I’ve seen firsthand that raw chemical composition is only half the battle in battery performance. The physical structure of the material—specifically particle size and shape—dictates the final energy density. We don’t just grind material; we engineer the microstructure to […]

Agglomerates Difficult to Disperse? How to Optimize the Particle Size Distribution of Cathode Materials with a Pin Mill ?

In the production of lithium-ion batteries, the performance of cathode materials—such as lithium cobalt oxide (LCO), nickel–cobalt–manganese oxides (NCM), and lithium iron phosphate (LFP)—directly affects energy density, cycle life, and safety. Among the common challenges in cathode material processing, agglomeration is one of the most critical. These agglomerates are often formed due to van der […]

How Can You Achieve High Purity and Fineness with Ultrafine Talcum Powder Grinding Solutions?

Talc is unique among non-metallic minerals. It is the softest mineral on earth with a Mohs hardness of 1, but its true industrial value lies in its platy (lamellar) structure and natural hydrophobicity. When we approach talcum powder ultrafine grinding, we aren’t just crushing rock; we are carefully engineering a functional additive that needs to […]

Why Are Silicon–Carbon Anodes the Key to Next-Generation High-Energy-Density Lithium-Ion Batteries?

Silicon–carbon (Si–C) anodes materials are regarded as one of the core enabling technologies for next-generation high-energy-density lithium-ion batteries. They are designed to overcome the intrinsic limitation of conventional graphite anodes, whose theoretical specific capacity is only 372 mAh/g, and to enable a major leap in battery energy density. I. Why Choose Silicon? Why Must It […]

What is the development status of ultrafine non-metallic mineral powders?

Ultrafine powders refer to a class of materials with particle sizes ranging from the micrometer to the nanometer scale. At present, the extensive application of non-metallic mineral powders in modern high-tech new materials is based on their unique functional properties. The functional performance of most non-metallic minerals is highly dependent on particle size, particle size […]

Jet Mill or Air Classifier Mill? Which Process Is the Optimal Solution for Ultrafine PEEK Grinding?

Polyetheretherketone (PEEK) is a high-performance specialty engineering plastic. It is renowned for its excellent heat resistance, chemical resistance, wear resistance, and mechanical strength. As a result, PEEK is widely used in aerospace, medical devices, automotive, and electronics industries. With the continuous upgrading of application demands, the need for ultrafine PEEK powders is steadily increasing. This […]

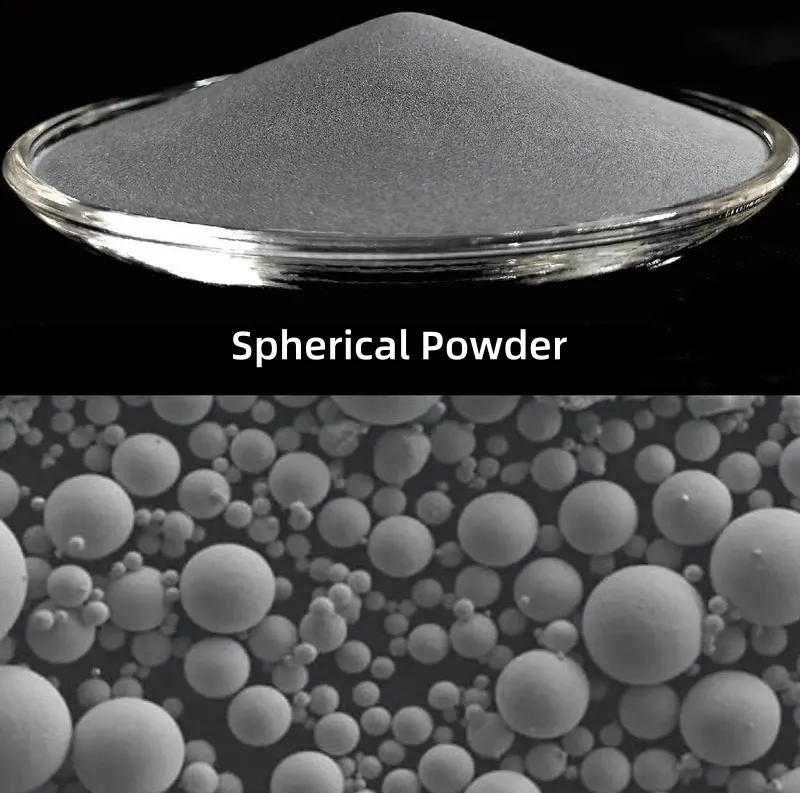

Spherical Graphite and Spherical Alumina : Why Does a Small Powder Multiply in Value After Becoming Spherical Powder?

With the rapid development of modern industry and advanced technologies, performance requirements for powder materials are becoming increasingly stringent. Materials must exhibit ultra-low impurity levels, fine particle size, and a narrow particle size distribution. Particle morphology has also become a critical quality indicator. Spherical powder stands out for its uniform particle size, smooth surface characteristics, […]

What Are The Preparation Processes for Ultrafine Powders?

In recent years, new material development has accelerated worldwide. Materials research is moving toward extreme states and higher performance. Among emerging materials, ultrafine powders have attracted significant attention. Current research on ultrafine powders mainly focuses on four aspects: preparation methods, microstructure, macroscopic properties, and applications. Among these, preparation technology is the most critical factor. There […]