Lithium battery performance encounter difficulties?

The goal of the lithium battery industry is to develop batteries with stronger functions, greater capacity, longer life, shorter charging times, and lighter weight. Lithium-ion batteries usually consist of a negative electrode (anode), a positive electrode (cathode) and a membrane. Lithium compounds used in lithium batteries have specific particle size distribution requirements, and the use of ultra-fine lithium powder can improve battery performance, including higher available capacity, longer service life, faster charging rate, higher efficiency, consistent discharge rate, and reduced size and weight.

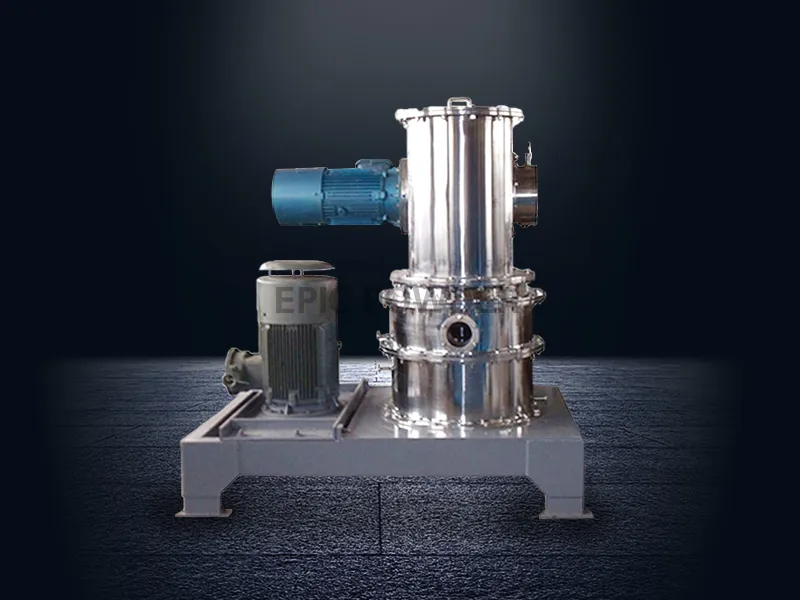

In addition to the mechanical and thermal resistance of the membrane, the quality and safety of the battery can be affected by chemical composition, shape, and particle size distribution of the active material, and the homogeneity of the battery. After extensive research and development, EPIC POWDER has a set of perfect lithium battery anode and cathode processing schemes and equipment that can meet complex process requirements, including dust-free feeding, magnetic separation, ultra-fine grinding, classification, powder transport, metering packaging, automatic batching, intelligent control, and other.

Typical materials of cathode materials for lithium-ion batteries

- LCO(Lithium Cobalt Oxide,LiCoO2)

- NCA(Lithium Nickel Cobalt Aluminum Oxide,LiNiCoAlO2)

- NMC(Lithium Nickel Manganese Cobalt Oxide,Li [NiCoMn] O2)

- LMO(Lithium Manganese Oxide,LiMn2O4)

- LFP(Lithium Iron Phosphate,LiFePO4)

- Lithium Carbonate(Li2CO3)

- Lithium Hydroxide(LiOH)

Introduction of anode materials for lithium-ion batteries

Lithium-ion battery anode materials include flake natural graphite, mesophase carbon microspheres, and petroleum coke-based artificial graphite. Carbon material is currently the main negative electrode material used in lithium-ion batteries, and its performance affects the quality, cost, and safety of lithium-ion batteries. The performance of anode materials is not only determined by the raw materials and process formula, but also by stable and energy-efficient carbon graphite grinding, spheroidizing, shaping, and grading technologies.

EPIC Has Helped Them Solve the Problem

We can provide processes and equipment that meet the following performance indicators

- Available particle size D50:3~45μm.

- Full ceramic protection, increased amount of metal <20ppb

- Complete Closed-loop grinding system, moisture increase <100ppm

- Hourly output of a single device can be more than 1000kg

- The linear speed of ceramic grinding disc and classifying wheel can reach 100m/s

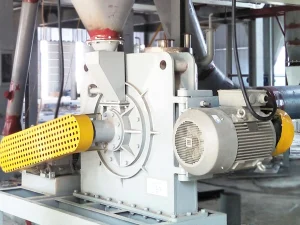

- Impact mill can directly replace jet mill to produce, single crystal NCM materials, saving 30% of energy consumption.