Pesticide

After the pesticide raw materials are finely pulverized, their uniformity, dispersion, and contact area are significantly improved, resulting in enhanced sterilization, insecticidal, and weeding effects , and a reduced use of pesticides . Furthermore, the ultra-fine powder has a large specific surface area, strong adsorption capacity, and resistance to rain washing, so as to maintain the long-term effect of pesticides. Correspondingly, due to the strong surface activity of ultra-fine powder, the decomposition rate of agricultural and sideline products and the environment is accelerated, leading to a reduction in pesticide residues and pollution.

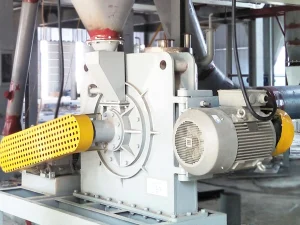

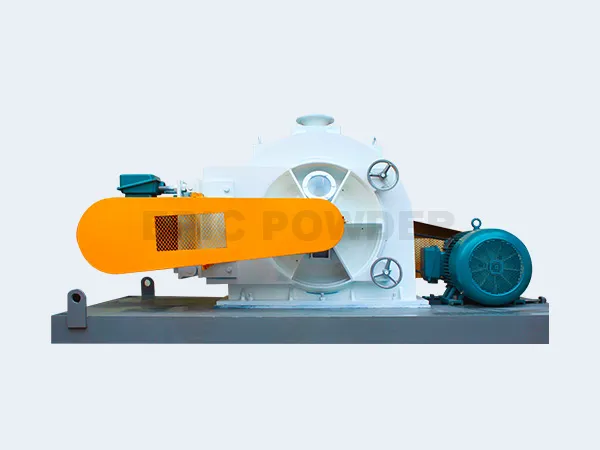

Our air classifying mill can grind pesticide raw materials to a size of 25-35 µm, while jet mills can reduce the size to 10 µm. In addition, we also provide dial grinders and hammer machines for rough grinding.

EPIC Has Helped Them Solve the Problem

We can provide processes and equipment that meet the following performance indicators

- Quick disassembly of equipment within 10 minutes.

- No dead angle, easy to clean.

- The produce collection efficiency is 99.9%.

- A low noise design with an 80dB noise level.

- Both on-line cleaning (CIP) and on-line sterilization (SIP) design are optional.

- Production Operation Protection (Isolation Cover/Glove Box).

- Query the process parameter storage and historical record.

- The design is explosion-resistant and provides full nitrogen protection.