The working principle of baking soda (sodium bicarbonate) used for flue gas desulfurization

Sodium bicarbonate (baking soda, NaHCO3) can be used as an adsorbent for flue gas desulfurization. It removes acidic pollutants in the flue gas through chemical adsorption. At the same time, it can also remove some inorganic and organic trace substances through physical adsorption. Spray the fine sodium bicarbonate powder directly into the high-temperature flue gas, and the sodium bicarbonate decomposes at high temperature to produce sodium carbonate Na2CO3, H2O and CO2.

NaHCO3 + HCl → NaCl + H2O + CO2

2NaHCO3 + SO2 + ½ O2 → Na2SO4 + H2O + 2CO2

NaHCO3 + HF → NaF + H2O + CO2

Generally, the flue gas temperature is between 140 and 250 °C. Due to the high activity of sodium bicarbonate adsorbents, a slight excess of sodium bicarbonate (stoichiometric factor between 1.1 and 1.3) is usually sufficient.

Due to transportation and storage, sodium bicarbonate raw materials are usually coarse particles (D50 value is about 200 microns). To achieve higher reactivity, the adsorbent must have a larger specific surface area. Therefore, the sodium bicarbonate must be ground to a certain fineness before being injected into the flue gas pipe. For example, to remove SO2, the fineness of sodium bicarbonate must reach D90 <20μm; and to remove HCl, only D90 <35μm is required. If the system is operated correctly, it can remove more than 95% of SO2; the removal rate of HCl can even reach 99%.

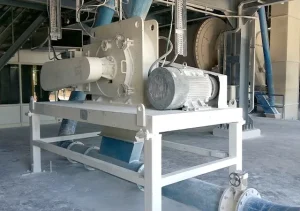

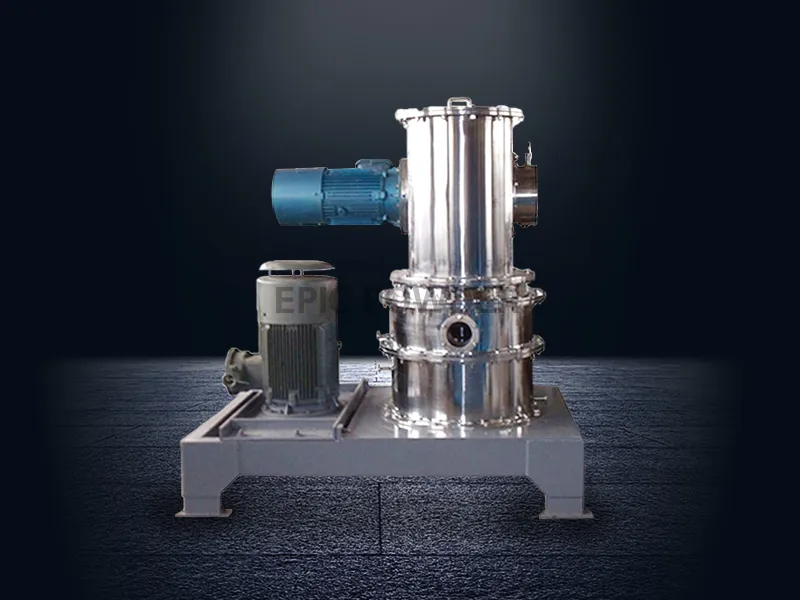

EPIC Has Helped Them Solve the Problem

We can provide processes and equipment that meet the following performance indicators

- Available particle size D50:3~45μm.

- Full ceramic protection, increased amount of metal <20ppb

- Complete Closed-loop grinding system, moisture increase <100ppm

- Hourly output of a single device can be more than 1000kg

- The linear speed of ceramic grinding disc and classifying wheel can reach 100m/s

- Impact mill can directly replace jet mill to produce, single crystal NCM materials, saving 30% of energy consumption.