In recent years, research and drug processing have changed. They used to focus on pharmacology but now aim to improve drug effects. Development will focus on refining drug particles. It will make them ultrafine, purify them, and add functions to them. Research and applications are focused on particles below the submicron level. The pharmaceutical industry has much literature. It shows that finely ground drugs are good for human absorption. They also act faster in the body and are used more by the body. We use size reduction technology to improve powder processing. It can boost the bioavailability of active pharmaceutical ingredients (APIs). This helps the drugs have their desired effects. It also aids in improving drug formulations.

In the pharmaceutical industry, jet mills are commonly used to reduce size. Ultrafine grinding is used more and more in the pharmaceutical industry. Jet mills are playing a bigger role in making ultrafine drug powders. The jet pulverizer is a key part of ultra-fine grinding equipment. It can grind materials into powders of a few microns. A jet mill uses high-speed airflow or superheated steam. It crushes materials by colliding, grinding, and shearing them.

The working principle of jet pulverizer in the preparation process of medicinal powder

After the air or gas is pressurized in the nozzle, the fast fluid jet is used to cause strong impact, shear, collision, and friction. These occur between the particles, between the gas and the particles, and between the particles and the wall and other parts. Also, the centrifugal force of the airflow separates the coarse and fine particles. This achieves ultra-fine crushing.

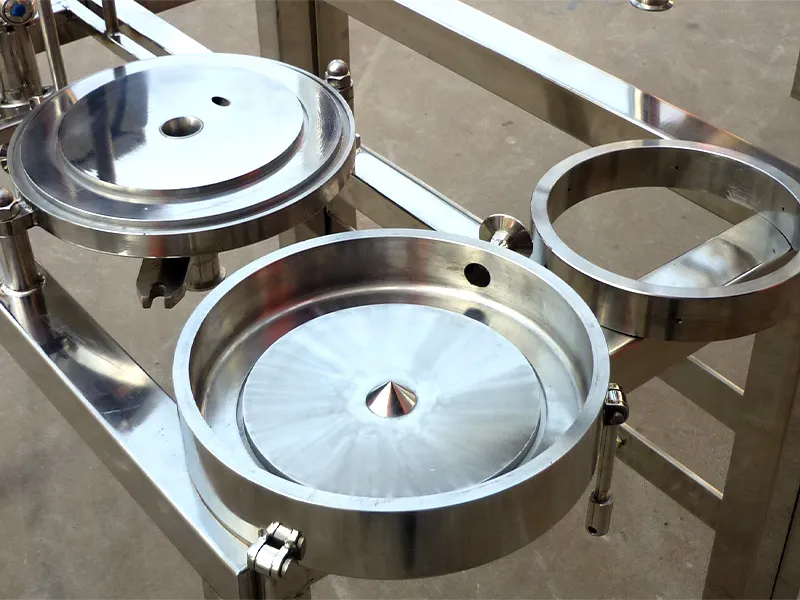

Types of jet mills

Jet pulverizer equipment can be divided into types by machine type. These types are: flat jet pulverizer, counter-jet jet pulverizer, target jet pulverizer, circulating tube jet pulverizer, fluidized bed (opposite jet), and grinder.

Characteristics of airflow crusher for drug crushing

(1) The range of particle sizes is narrow. The average size is small. High-pressure airflow crushes the particles. Airflow rotation and the force of the precision classifier sort the particles by size. The resulting product has a narrow particle size range. It has a fine average particle size and a D50 size. Between 5~10μm.

(2) The powder has good shape and high purity. The jet mill makes it spherical, smooth, and regular. It disperses well and has little wear during crushing.

(3) Suitable for low melting point and heat-sensitive drugs: The airflow pulverizer is powered by compressed air. The high-speed jet pneumatic produces the Joule Thomson effect. The pneumatic collides at the nozzle, reducing the system’s temperature. This offsets the effects of drug collision and friction. heat. The chamber’s temperature can reach tens of degrees Celsius. This is good for making low melting point and heat-sensitive drugs.

(4) The pulverizer seals well and is not polluting. Its good sealing makes the product yield high. Crushing happens under negative pressure. There is no leakage, no pollution, and it can be operated aseptically.

(5) The crushing is continuous. It uses closed-circulation and automatic control. The operation is simple.

(6) The jet mill can crush, mix, and dry drugs online. It can also modify drug powder at the same time. For example, some drugs are sprayed with liquid during the crushing process, covering and modifying the particles.

Controlling the Particle Size of Pharmaceutical APIs

In airflow crushing, the crushing conditions are different for different materials. The material will crush differently. This happens under different crushing conditions and settings. Process parameters are often controlled during the crushing process. This control relies on empirical rules. Also, there is a lack of relevant experimental results. And, there is a lack of theoretical guidance. They are for controlling process parameters during crushing.

You use an airflow mill to control the size of pharmaceutical API particles. But, you need to understand the structure of the airflow powder. You also need to understand what affects it. These factors include: the better parts, the rest of the content, the properties of the starting material, and the gas. Various factors will have an impact. Select the appropriate hardware configuration to maintain stable quality standards effectively.