The airflow classifier is a widely used equipment in the metal powder industry. By classifying the size of powder particles, it can effectively improve product quality and market competitiveness. This article will introduce the working principle of air classifiers. It will also cover their application areas and advantages.

working principle

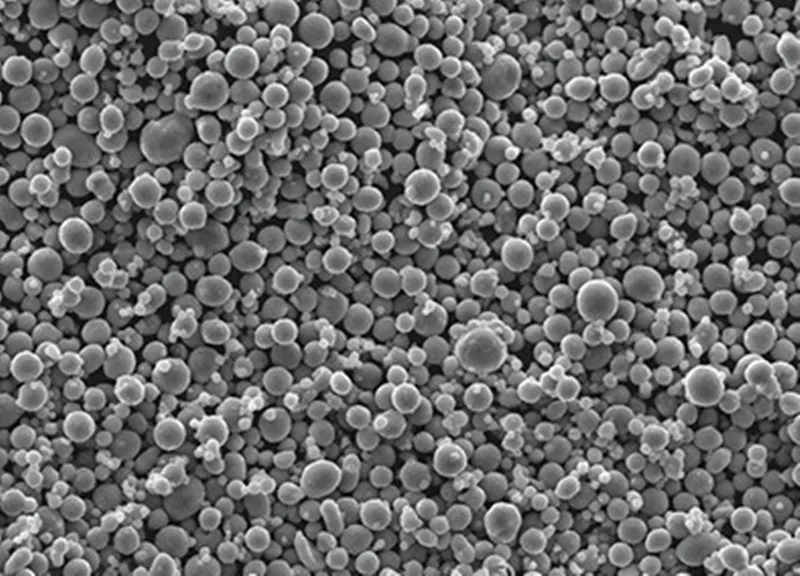

Air Jet Sieve uses the principle of gas flow to classify metal powder. The equipment suspends the powder on the sieve holes by blowing high-speed gas. This divides the powder into different size classes based on differences in size and shape. This classification method is very important in the metal powder industry. The particle size directly affects the powder’s performance and use.

Application areas

1. In metal powder production, an air flow classifier can remove particles that do not meet the specs. It does this through classification. This ensures the quality and consistency of the product.

2. Powder metallurgy uses metal powder. An airflow classifier can separate particles of the right size. This achieves the needed raw material ratio and process requirements.

3. In metal 3D printing, the size of the powder particles is important. It affects the printing and product quality. Classify metal powder with an airflow classifier. This gets a more even particle size. It improves printing quality and success rate.

4. In the coating industry, air flow classifiers can classify and filter metal powder coatings. They ensure the evenness and stability of the coating during application. This process improves the coating’s quality.

Advantage

1. The airflow classifier has an automated grading system. It can grade continuously and automatically. This greatly boosts production efficiency.

2. The airflow classifier can achieve precise classification with the right settings. It can meet particle size needs in different fields.

3. The airflow classifier can adjust its specifications and parameters. It does so according to the product’s requirements. It can adapt to the classification needs of powders of different sizes and shapes.

4. The airflow classifier is reliable. It uses advanced technology and design. It has stable performance and can run for a long time. This cuts downtime and maintenance costs.

Airflow classifiers have been widely used in the metal powder industry. By categorizing powders, we can enhance product quality and market competitiveness. The metal powder industry is experiencing rapid growth. Air classifiers will continue to play a crucial role in it. They will also continue to improve to meet the needs of different industries.