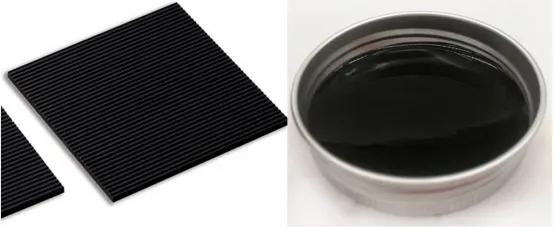

Conductive carbon black is a typical type of specialty carbon black. It offers high electrical and thermal conductivity. Moreover, it has low production cost and good oxidation stability. It also features low density, enhancing material performance. As a result, it is widely used in conductive plastics. Additionally, it plays a key role in conductive rubber. It is also applied in conductive inks for electronics. Furthermore, it is used in battery electrodes and supercapacitors.

The conductivity of conductive carbon black is typically 10⁻¹ to 10⁻² S/cm. It is a typical type of specialty carbon black. It shows high electrical and thermal conductivity. Moreover, it has low cost, oxidation stability, and low density. Compared to metal powders or fibers, it offers clear advantages. Meanwhile, it is easy to process and mold into composites. It also reinforces materials, enhancing mechanical strength. Therefore, it is an ideal conductive filler. As a result, it is widely used in conductive plastics. In addition, it is used in conductive rubber and inks. It also finds use in battery electrodes and supercapacitors.

Battery field

Lithium-ion battery

Conductive carbon black is a key additive in lithium-ion battery electrodes. It enhances the conductivity of electrode materials effectively. As a result, it improves charge-discharge performance and cycling stability. This helps increase the energy density and lifespan of batteries.

Nickel-metal hydride batteries: used in the negative electrode. Conductive carbon black acts as an electron carrier and conductive additive. It helps the anode material perform electrochemical reactions more efficiently. This reduces electrode polarization during charging and discharging. As a result, it enhances battery performance and cycle life. It also minimizes gas generation and other side reactions.

Nickel-cadmium batteries: used in the negative electrode. Conductive carbon black improves conductivity of anode materials. It helps reduce internal resistance of the battery. As a result, it enhances high-current discharge capability. It also improves charge-discharge efficiency. Moreover, it reduces energy loss and heat generation.

Rubber and plastic products

Antistatic products

Used to produce anti-static rubber products, such as mats and conveyor belts. Also applied in anti-static rubber soles and medical rubber goods. It effectively prevents the generation and buildup of static electricity. This helps avoid damage to equipment and harm to personnel. Produce conductive plastic products, such as conductive films, conductive fibers, conductive leather products, etc., which have important applications in electronic packaging, electromagnetic shielding and other fields.

Ordinary rubber and plastic products: It can improve the conductivity of rubber and plastic. It makes them have certain antistatic properties and reduces the impact of static electricity on products. At the same time, it can also improve the mechanical properties and processing properties of materials. For example, adding conductive carbon black to products such as automobile tires, rubber seals, and plastic pipes can improve their performance and quality.

Cable material

Power cable shielding materials

Electromagnetic interference shielding:

Conductive carbon black is added to cable shielding layers. It effectively blocks external electromagnetic interference. This ensures stable and accurate power signal transmission. For example, urban power grids require strong EMI protection. It helps prevent interference from nearby electronics and signals.

Electric field homogenization:

Uneven electric fields in cables can cause partial discharges. These discharges reduce cable safety and lifespan. Conductive carbon black improves conductivity across the shielding layer. As a result, it helps evenly distribute the electric field. This reduces field concentration and lowers discharge risk.

Semi-conductive cable materials

Semiconductive shielding layer:

In medium- and low-voltage cables, it is used in semiconductive shielding layers. Conductive carbon black is mixed with rubber or plastic base materials.

This forms a semiconductive composite for cable shielding. It provides a buffer between the conductor and insulation layer. This prevents electric field concentration caused by surface defects.

As a result, it protects the insulation from electrical damage.

Improved processing performance:

Adding conductive carbon black enhances material processability. It makes cable materials easier to extrude and shape. This improves production efficiency and product quality. Additionally, it increases mechanical strength and wear resistance. Thus, it extends the cable’s service life.

Electronic printing and coating industry

Conductive inks and coatings:

Adding conductive carbon black gives inks and coatings conductive properties. It is used for printing circuit boards (PCBs), electronic displays, and electromagnetic shielding coatings. For example, in mobile phones and computers, conductive inks enable circuit connections and conductivity.

In sensitive environments, such as communication stations, MRI rooms, and military equipment,

electromagnetic shielding coatings are used to block or reduce external interference. They also prevent internal electromagnetic signal leakage. Conductive carbon black enhances the shielding performance of these coatings. Its conductive network absorbs and reflects electromagnetic waves, providing effective shielding.

Electronic printing:

Conductive carbon black can be used to manufacture anti-static clothing and smart textiles. In environments where static control is needed, wearing anti-static clothing helps prevent damage to electronic devices and harm to the human body.

Additionally, conductive carbon black can be used in screen printing inks. It enables the printing of conductive patterns or text on various materials, such as plastic, paper, and metal. Screen printing offers fast printing speed, high precision, and versatility.

When combined with conductive carbon black, it allows the production of a wide range of conductive printed products.

Other fields

Seals:

Adding conductive carbon black to automotive door and window seals gives them some conductivity. This helps prevent static buildup from friction, which could attract dust. It also improves the aging resistance and sealing performance of the seals.

Brake Pads:

Adding conductive carbon black to brake pad friction materials enhances their conductivity and thermal conductivity. This allows the brake pads to dissipate heat more effectively during braking. As a result, it lowers braking temperatures and improves braking performance and safety.

Conclusion

In conclusion, conductive carbon black plays a vital role across various industries, from enhancing the performance of electronic devices and automotive components to improving the functionality of materials used in environmental protection and safety. Its ability to provide conductivity, electromagnetic shielding, and improved mechanical properties makes it an invaluable additive in products such as conductive plastics, anti-static materials, brake pads, and coatings. As technology continues to evolve, the applications of conductive carbon black are expected to expand, offering even greater opportunities for innovation and performance improvement across diverse sectors.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !