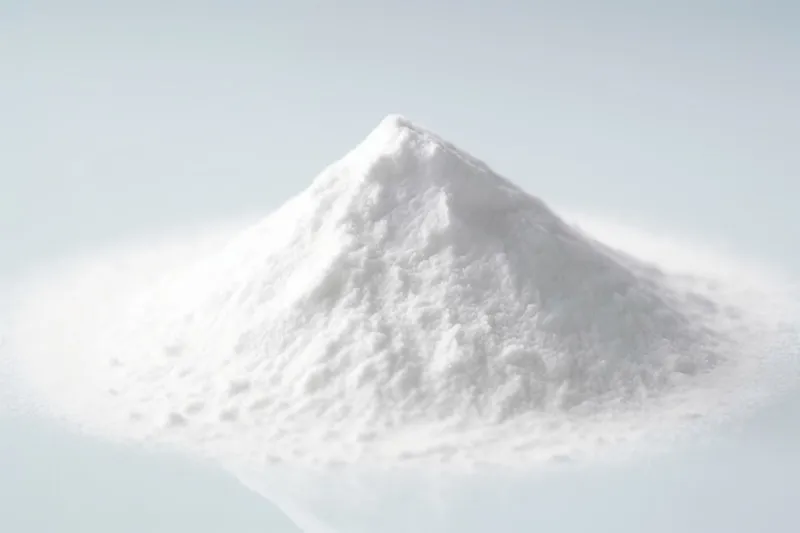

Calcium carbonate powder is widely used in industrial production and has many common applications and effects.

Calcium carbonate powder is a powder, block.

These industries include rubber, plastic, paint, and water-based coatings. Also, the construction (dry mortar, concrete), and fireproof ceiling industries.

Product parameters: CaCO3 calcium carbonate: 98.8% whiteness 88-96 sieve residue (30.8um) “PH value 9 + 0.5 Fe2O3 iron oxide “0.03 siO2 silicon dioxide “0.04 MgO magnesium oxide <0.1 Ai2O3 aluminum oxide “0.01 burnt amount 43.5 moisture 0.05 calcium oxide 55

Calcium carbonate powder application scope and efficacy:

1. Heavy calcium carbonate powder for rubber industry Rubber – heavy calcium carbonate powder for rubber: 400 mesh, whiteness: 93%, calcium carbonate: 96%.

2. Plastic industry with heavy calcium value: plastic-plastic masterbatch, color masterbatch with heavy calcium carbonate powder (bicarbonate powder) 400 mesh.

3. Paint industry with heavy calcium powder: paint – latex paint with heavy calcium carbonate (heavy calcium powder) 800 mesh or 1000 mesh, whiteness: 95%, calcium carbonate: 96%) Calcium carbonate in the paint industry is also a large amount, for example, in the thick paint in the dosage of more than 30%.

4. Heavy Calcium Powder for Water-based Coating Industry comes in 800 or 1000 mesh. It has 95% whiteness and 96% Calcium Carbonate. Calcium Carbonate is widely used in water-based coatings. It stops paint from settling, makes it easy to spread, and gives it a good shine. The dosage in water-based coatings is 20-60%.

5. Paper industry with heavy calcium powder: paper with heavy calcium carbonate (heavy calcium powder): 325 mesh, whiteness requirements: 95%, calcium carbonate content: 98% of the important role of calcium carbonate in the paper industry. It can ensure the strength and whiteness of paper, and the cost is low.

6. The construction industry uses heavy calcium powder in dry mortar and concrete. It needs dry mortar with heavy calcium carbonate. The calcium carbonate must be 325 mesh, have 95% whiteness, and 98% calcium carbonate content. Calcium carbonate is important in concrete. Not only can reduce production costs, but also increase the toughness and strength of the product.

7. Heavy calcium carbonate is for the fireproof ceiling industry. It is 600 mesh. It must be 95% white and have 98.5% calcium carbonate. The production process of fireproof ceilings needs it. It improves the product’s whiteness and brightness. It also increases fire resistance.

8. The artificial marble industry uses heavy calcium powder. The powder is 325 mesh, 95% white, and has 98.5% calcium carbonate. It is pure and unadulterated. Calcium carbonate is widely used to make artificial marble.

9. Floor tile industry with heavy calcium powder. This heavy calcium powder is 400 mesh. It must be at least 95% white and have 98.5% calcium carbonate. It must also be pure. Calcium carbonate is used in floor drilling. It increases product whiteness and strength. It also makes the product tougher and cheaper to make.