Modified calcium carbonate powder is a versatile material. Its improved properties make it better than natural calcium carbonate. So, it is widely used in many industries. This modified form is made by processes that change its surface, size, and chemistry. It is now suitable for use in plastics, paints, paper, and pharmaceuticals. The changes can improve the material’s dispersibility and compatibility. They can boost their performance in different formulations. This will enhance product quality and efficiency. Surface-treated calcium carbonate is now a key additive. It is cheap and helps make manufacturing processes more sustainable. Its ability to boost strength and cut pollution makes it popular. Manufacturers want to optimize their products.

Surface modification is key to enhancing calcium carbonate’s performance. It improves its use and expands its market. In the future, calcium carbonate will focus on functionalization and specialization. There will be a growing demand for various surface-modified special calcium carbonates.

We must base the surface modification of calcium carbonate powder on its mechanism. It must also consider the substrate, formula, and the needs of organic polymers in the final products. After careful thought, a surface modifier is selected. The process and equipment for surface modification are then determined. This will produce qualified active calcium carbonate products.

After surface modification, calcium carbonate will be better used in the following fields:

Modified calcium carbonate powder for polyvinyl chloride (PVC)

Modified calcium carbonate has evenly distributed particles. They are in their original, unagglomerated state. This is better than ordinary calcium carbonate. It has excellent compatibility and dispersibility with PVC resin. It is easy to plasticize, does not stick to rollers, and processes well. It also improves processing efficiency. Also, the product’s breaking strength and elongation are much better. Its physical and mechanical properties are good.

Modified calcium carbonate powder for polypropylene (PP)

A coupling agent, PTHF, modified the surface of light calcium carbonate. PTHF is a tetrahydrofuran homopolyether. This reduced calcium carbonate’s oil absorption value to 22% and its contact angle to 68.6°. The modified calcium carbonate powder was filled into polypropylene and dispersed well in it. This improved the tensile strength to some degree. The composite’s elongation at break reached 28.47%, and its impact strength was 6.7 kJ/m².

High-density polyethylene (HDPE)

An aluminate coupling agent mechanochemically modified heavy calcium carbonate. Aluminate coupling agent bonded to the surface of calcium carbonate particles. Its use improved their dispersibility. More Surface-treated calcium carbonate in HDPE reduced the composite’s wear and friction work. It improved its anti-friction performance. At 8phr, the composite material had the best properties. The tensile and impact strengths increased by 4.46% and 24.57%, respectively.

Low-density polyethylene (LDPE)

Using 1.5% stearic acid and 0.5% DL-411 aluminate, the modified calcium carbonate’s activation index is 99.71%. Its oil absorption value is 46.19mL/100g. The final sedimentation volume is 2.3mL/g. The viscosity of a mixture of 10g of the Surface-treated calcium carbonate and 100 mL of liquid paraffin is 4.4Pa·s. The modified calcium carbonate is filled into low-density polyethylene (LDPE). The composite material has good mechanical properties at a 10% calcium carbonate content.

ABS plastic

After surface modification, nano calcium carbonate disperses better in organic media. Its surface changes from hydrophilic to lipophilic. Using it in ABS resin can improve its mechanical properties. They are impact strength, tensile strength, surface hardness, bending strength, and heat deformation temperature.

Modified calcium carbonate for polyester (PBAT)

The surface of calcium carbonate is modified by the double-layer coupling agent coating method. The modified calcium carbonate powder filling can reach 50%. The composite material products have good mechanical properties. The PBAT resin matrix fully coats the Surface-treated calcium carbonate particles in the composite. There is no dissolution. This improves their mutual fluidity.

Radiation cross-linked EPDM

We modified the calcium carbonate in situ using titanate coupling agent 105. It has unsaturated functional groups. This improved its dispersibility. In the radiation cross-linked EPDM, the modified calcium carbonate’s surface reacted with EPDM. This was due to the oleic acid group. This allowed the calcium carbonate to join the EPDM’s cross-linking network. The composite’s tensile strength, 100% elongation stress, and Shore A hardness improved. Thus, the calcium carbonate reinforced the radiation cross-linked EPDM.

Polylactic acid (PLA)

Coupling agents can modify the surface of calcium carbonate. This increases its specific surface area and contact area with the matrix. Under stress, more silver streaks and deformed areas will form. They will absorb a lot of energy, toughening and strengthening the material.

PVC coated fabric

Modified heavy calcium carbonate can improve the compatibility of PVC paste resin compounds. Using it in the same amount as ordinary heavy calcium carbonate can achieve a low viscosity. It will boost adhesion to polyester cloth, cut adhesive use, and improve the coating’s feel. A 40% increase in usage has no adverse effects. It does not harm the material’s performance, properties, or thermal welding.

Polyvinyl chloride (PVC) fire hose

Modified calcium carbonate is better than ordinary calcium carbonate. Its particles are evenly distributed and do not agglomerate. Some of them exist in the state of nanoparticles. Therefore, filling them in PVC fire protection pipes can improve the system’s performance. It will also toughen and strengthen the products. This will improve their physical and mechanical properties.

PVC cable materials and flame retardant masterbatch

Heavy calcium carbonate is modified by aluminate, titanate, and stearic acid. This composite filler makes high-performance PVC cables and flame-retardant masterbatches. A trend in developing heavy calcium carbonate is to use composite modifiers for its surface modification.

Polyetheretherketone

Using sulfonated hyperbranched polyaryletherketone to modify calcium carbonate whiskers can improve their dispersibility in the matrix. It can improve the interaction between the two phases. It will also reduce the composite’s melt viscosity at the processing temperature. At the same time, the composite’s Young’s modulus, flexural modulus, and toughness are improved.

Plastic film

Calcium carbonate is widely used in thin films. After treatment, calcium carbonate mostly combines with the base resin. This is via surface adsorption, physical entanglement, and van der Waals forces. It results in a more uniform dispersion and better film performance.

Food plastic packaging

Nano calcium carbonate is an ultra-fine material for plastic filling. It can greatly improve product performance. Studies show that nano food packaging materials have barrier, antibacterial, and fresh-keeping properties. They have been used to package beer, beverages, fruits, vegetables, and dairy products. To get a filling state with good dispersion and small particles, we must reduce the nano action energy. Now, mechanical dispersion is common. Or by adding dispersants, drying, etc.

Modified calcium carbonate for breathable membrane

The breathable film is made by adding about 50% of special calcium carbonate to PE or PP carriers. Then, it is directionally stretched at a certain ratio after extruding it into a film. It is widely used in pharmaceutical films, surgical gowns, medical gloves, sanitary napkins, baby diapers, disposable sheets, cling film, composite films, and cooked food packaging bags. The surface-modified calcium carbonate has improved hydrophobicity. It has excellent dispersion and thermal stability. It can be used to make breathable films.

Room temperature vulcanizing (RTV) one-component silicone rubber sealant

A silane coupling agent modified the surface of ultrafine calcium carbonate. The modified calcium carbonate greatly reinforced the sealant. It had a tensile strength of 0.57MPa and a max elongation of 159.60%.

Polyurethane sealant

Calcium carbonate was modified by copolymerizing methyl methacrylate (MMA) and a silane coupling agent, KH570. The water contact angle of the Surface-treated calcium carbonate was 60°, and the sedimentation value was 1.36 ml/g. It mixed well with polyurethane and became thixotropic. The mechanical properties of polyurethane improved more than those of unmodified calcium carbonate.

Modified calcium carbonate for silicone glue

Nano calcium carbonate can partly replace white carbon black in silicone adhesive. It is the main raw material for the production of silicone adhesive. Nano calcium carbonate, as a filler in silicone adhesive, can cut costs. It improves processing and boosts the adhesive’s tensile and tear strength. By controlling the crystal form, particle size, and surface treatment of nano calcium carbonate, we can make products with superb thixotropic and anti-sagging properties.

Rubber products

Surface-modified activated calcium carbonate boosts rubber’s strength. Its performance matches that of white carbon black. It is often used to reinforce white and colored rubber products. It can be used to make tire cushion rubber, inner tubes, bicycle tubes, transmission belt covering rubber, hoses, rubber products and shoes. It is also suitable for natural rubber, SBS and latex. It has a significant reinforcing effect in SBS and has good coloring performance.

Natural rubber vulcanizate

Calcium carbonate was modified by resorcinol and hexamethylenetetramine. The Surface-treated calcium carbonate vulcanizate had much better properties than the unmodified version. Natural rubber vulcanizate had a 130% higher tensile strength and a 70% higher tear strength than unmodified calcium carbonate. Its tensile strength was also 101% higher.

Styrene Butadiene Rubber (SBR)

The CPB-modified vulcanized rubber outperforms unmodified calcium carbonate by 60%. It is 70% better in 300% elongation stress and 30% better in tear strength.

Semi-steel radial tire inner liner

Adding 40 parts of modified calcium carbonate to the airtight layer of a semi-steel radial tire can improve the rubber’s airtightness. It has little effect on the rubber’s anti-flexing and processing performance. Tests show that using 40 parts of Surface-treated calcium carbonate in the airtight layer improves its airtightness by 30% over the ordinary layer. The cost is also 3.65 yuan/kg lower, with no impact on the tire’s high-speed or durability performance.

Modified calcium carbonate powder for papermaking filler

Starch-coated modified calcium carbonate is used as papermaking filler. The Surface-treated calcium carbonate has strong shear resistance and a high retention rate. This improves the paper’s strength and slows its decline.

Reconstituted tobacco

Sodium hexametaphosphate and citric acid modified calcium carbonate (1:1 ratio). The Surface-treated calcium carbonate in the tobacco had 8.25% more ash than commercial calcium carbonate. The smoke indicators and sensory tests were better than the commercial calcium carbonate.

Modified calcium carbonate powder for powder coating

Surface-treated calcium carbonate is a skeleton in powder coatings. It increases coating thickness and improves wear resistance and durability. Modified calcium carbonate powder is cheaper than other inorganic fillers. So, it can lower the cost of powder coatings and increase their powdering rate and spray area.

Latex paint

Modified nano-calcium carbonate made latex coatings with a PVC of 43%. The coatings with modified nano-calcium carbonate had a smooth, dense surface. Their stain, scrub, and aging resistance were greatly improved. Of the additives, the best at improving tensile strength was a mix of stearic acid and sodium sulfonate-modified nano-calcium carbonate. The stearic acid and titanate-modified nano-calcium carbonate boosted stain and scrub resistance.

Electrophoretic paint

Calcium carbonate is modified by hydrated fluorosilicic acid. A mix of amorphous silicon and calcium fluoride coats the surface of the calcium carbonate. This forms a dense film that greatly improves its acid resistance. It can be used for weakly acidic anodic electrophoretic paint.

PVC car chassis anti-stone impact primer

Calcium carbonate, with a particle size of 40-80nm, is modified with fatty acids or their salts. It has good thixotropy and is used in a PVC anti-stone impact primer for car chassis. The primer has good thixotropy and yield value.

Ink

The ink made with modified calcium carbonate has many benefits. It has a good body and viscosity. It prints well, dries quickly, and has no side effects. Its small particles give it excellent qualities for ink products. It disperses well, is transparent, and has a great gloss and hiding power. It also absorbs ink and dries quickly. So, the printed products are delicate, and the dots are complete. Since the rise of resin binders in inks, Surface-treated calcium carbonate has almost replaced other fillers. It is very stable.

Toothpaste

Guangdong Lafang Personal Care Products Co., Ltd. It uses silica to coat micron-sized, spherical calcium carbonate particles. This modifies the surface of calcium carbonate, a toothpaste abrasive. The modified calcium carbonate is more compatible with fluoride than the same-wear toothpaste.

Daily necessities

Adding active nano-scale calcium carbonate to cosmetics makes them smooth. As an additive, it can be made into setting powder. It will dim the foundation powder, help it stick to the skin, and absorb some oil and sweat. It can be used in smooth powder, as it does not irritate the skin, has a uniform color, and provides some coverage.

Artificial granite

Surface-treated calcium carbonate has low oil absorption. It is a key raw material for artificial stone.

Composite conductive powder

Coating and modifying calcium carbonate improves its acid resistance. Then, it is compounded with polyaniline to make a conductive composite powder. This gives calcium carbonate good conductivity. It also overcomes the difficulty of processing and shaping pure polyaniline. The result has great application potential.

lubricating oil

Adding modifiers to produce active nano-calcium carbonate during digestion can reduce the harm that surfactants cause to lubricating oils. It can also improve the dispersion stability of the nano-calcium carbonate in the oils. This, in turn, enhances their anti-wear and friction-reducing properties.

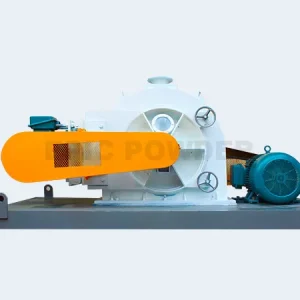

4 types of Calcium Carbonate Surface Coating Machine

A surface coating machine modifies the surface of calcium carbonate powder. As a result, the property of the ground calcium carbonate powder will be changed. Coated calcium carbonate powder has unique traits. So, it can be used in many areas.

Different types of powder coating machine

Our EPIC Powder Machinery company offers clients various mineral powder coating machines. They are a vortex mill, a coating mill, a three-roller coating machine, and a high-speed mixing coating machine.

The vortex mill coating machine has a conical rotor and stator. It controls fineness and output by adjusting their clearance. Its strong eddy current flow field crushes the material instantly. So, it stays in the cavity for a short time, without heating.

A new vortex mill coating machine with a classifier is the best coating solution for calcium carbonate in China.

A three-roller coating machine can coat powder surfaces. It does this by changing the cyclone vortex with three moving rotors. It can generate heat from friction. So, it doesn’t need a heater. This will save you money.

The high-speed mixing coating machine is for modifying materials. It can use silane and other additives. They require high temperatures and long reaction times.

Choose a right modified powder machine

There are various of powder coating manufacturing machine for your selection. So you need to compare these different machines to pick out a suitable one. Here is a chart to give you a quick overview of their respective advantages.

| Coating Machine Type | Coating Rate | Features |

| Vortex Mill Coating Machine | 98% | Continuous production,high coating rate, low stearic acid comsumption.suitable for large scale pro-duction and produce high-end product. it is alwaysused to equip with ball mill plant production |

| Three-roller Coating Machine | 95% | Continuous production,which is suitable for largescale production with less investment lt is alwaysused to equip with micro powder roller mill plantproduction. |

| Pin Mill Coating Machine | 99% | It has large output, high efficiency and high coverage rate, and is suitable for the production of high-end modified calcium carbonate. |

The vortex mill and three-roller coating machines can modify continuously. While the pin mill coating machine is the most efficient.

In addition, their coating rates are different. The coating rate of vortex mill coating machine can reach 98%, and the pin mill coating machine can reach 99%. At the same time, the coating rate of three-roller coating machine can reach 95%.

On the other hand, they have different capacity. You need a rough estimate of how many finished products you need per hour or per day.

If you don’t know much about powder surface grinding coating machines, please message us. We can provide you with our coating machine brochure and our engineers also can solve your problems.